Single-component polyuria preventive coating for agricultural irrigation concrete drainage channel and water duct, and preparation method of single-component polyuria preventive coating

A technology for protective coatings and agricultural irrigation, applied in the field of polyurea, can solve the problems of high cost of small-scale construction, hinder the development of polyurea materials, and complex environment, and achieve simple and convenient construction methods, prolong operation time, and reduce use costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

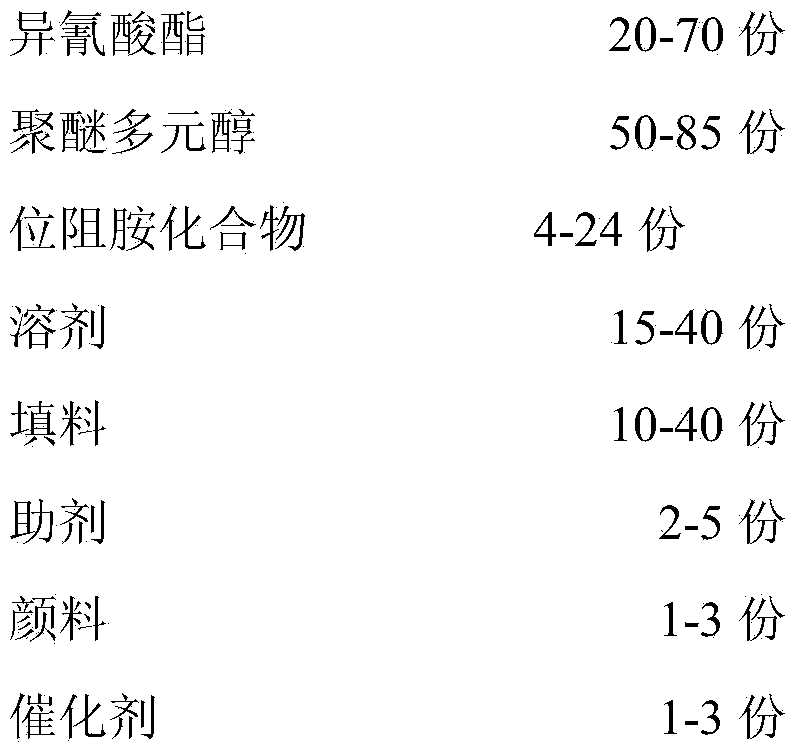

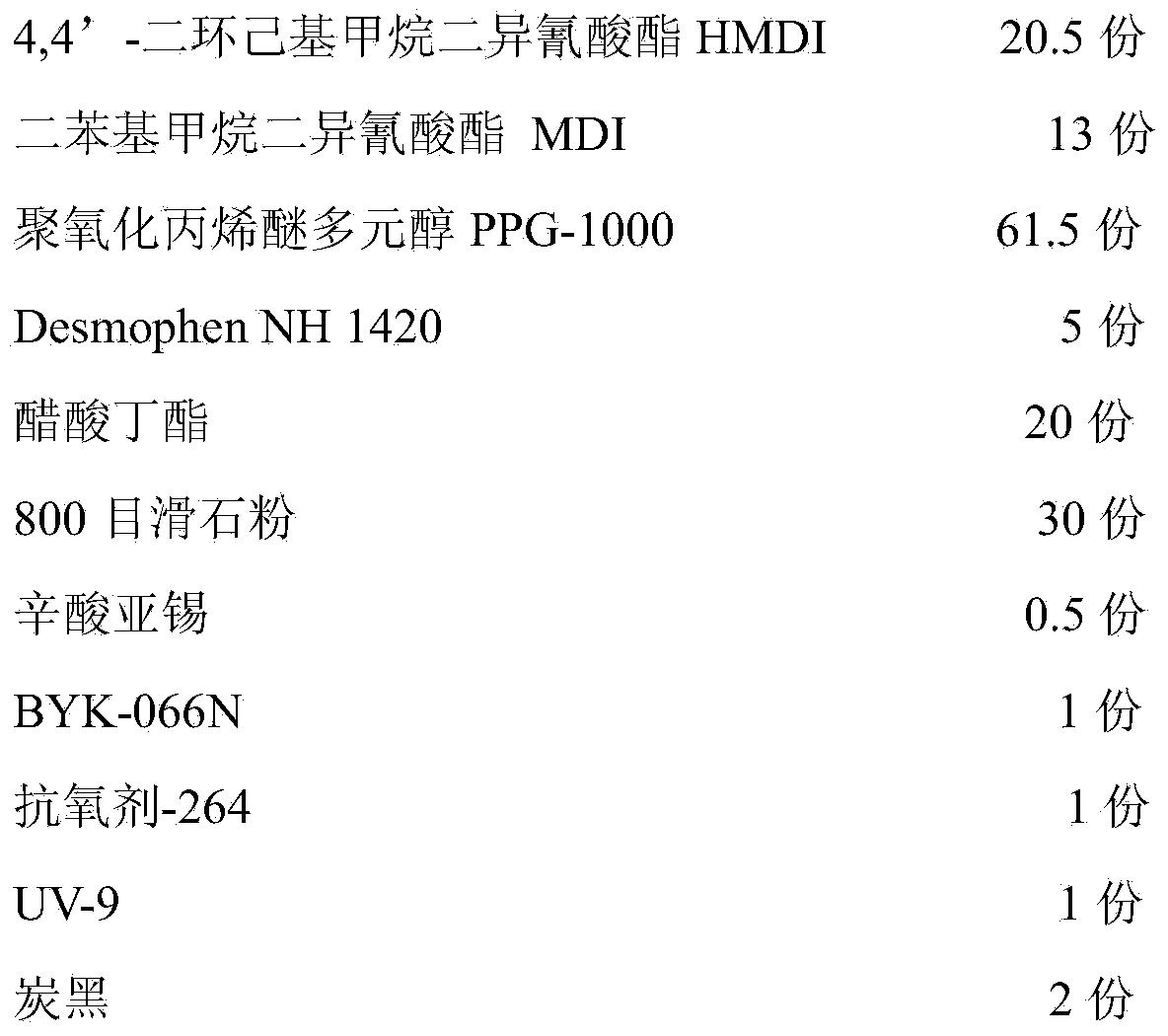

[0031] This embodiment discloses a single-component polyurea protective coating for agricultural irrigation concrete drainage channels and water pipes, including the following components in weight ratio:

[0032]

[0033] The one-component polyurea protective coating is prepared by the following steps:

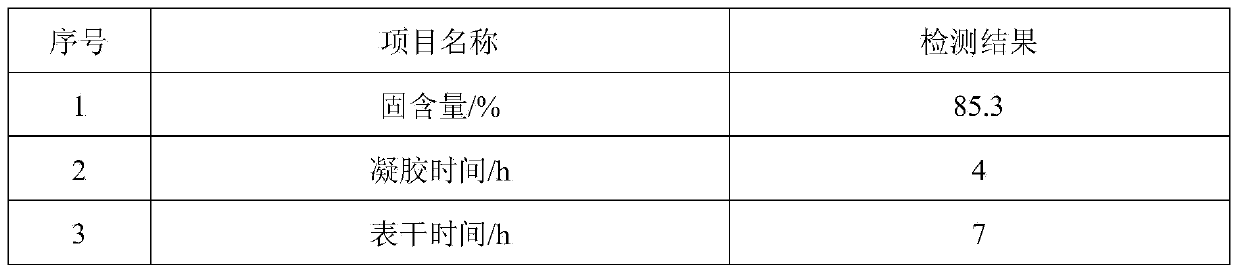

[0034] Add polyoxypropylene ether polyol PPG-1000, Desmophen NH1420, 800 mesh talc and carbon black into the container according to the above weight ratio, stir the liquid material at low speed for 5 minutes, heat it to 110-120°C, turn on the vacuum pump, The vacuum degree is -0.1~-0.08MPa, vacuum dehydration is 2h, the small amount of water contained in the raw material is removed, the water content is detected to be below three ten thousandths, and the liquid material temperature is about 25℃; then butyl acetate and HMDI are added Into the container, the temperature is raised to 50°C, and the reaction is stirred for 1 hour. After the exothermic reaction is over, add diphenylmetha...

Embodiment 2

[0041] This embodiment discloses a single-component polyurea protective coating for agricultural irrigation concrete drainage channels and water pipes, including the following components in weight ratio:

[0042]

[0043]

[0044] Add the polyoxypropylene ether polyol PPG-2000, Desmophen NH1420, 800 mesh talc and carbon black into the container according to the above weight ratio, stir the liquid at low speed for 5 minutes, then heat it to 110-120°C, turn on the vacuum pump, The vacuum degree is -0.1~-0.08MPa, and the vacuum dehydration is 2h to remove a small amount of water contained in the raw material. The detected moisture content reaches below three ten thousandths, and the liquid material temperature is cooled to about 25°C. Then add butyl acetate and hexamethylene diisocyanate trimer to the container, raise the temperature to 50°C, stir and react for 1 hour, after the end of the reaction exotherm, add MDI and dibutyltin dilaurate, and slowly raise the temperature to 70 ~8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com