Thermosetting acrylic paint for metal products and preparation method thereof

A metal product, thermosetting technology, applied in the direction of coating, can solve the problems of high temperature sensitivity, poor solvent resistance, insufficient plumpness, etc., and achieve the effects of good environmental protection, convenient construction and various colors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Example 1: Get 40 parts of methyl methacrylate, 40 parts of ethyl methacrylate, 30 parts of polyvinyl alcohol, 35 parts of styrene, 2 parts of talcum powder, 2 parts of quartz powder (174 μm), 1 part of ammonium persulfate 13 parts of emulsifier Dowfax2A, 10 parts of methyl hydroxypropyl cellulose (5% aqueous solution), 2 parts of sodium bicarbonate, 2 parts of lauryl mercaptan, 1 part of NaOH, 1 part of calcium stearate, 1 part of zinc oxide , 60 parts of xylene. The preparation method comprises the following steps: weighing xylene according to the formula ratio, heating to 100° C., adding other materials, and stirring for 30 minutes to obtain the product.

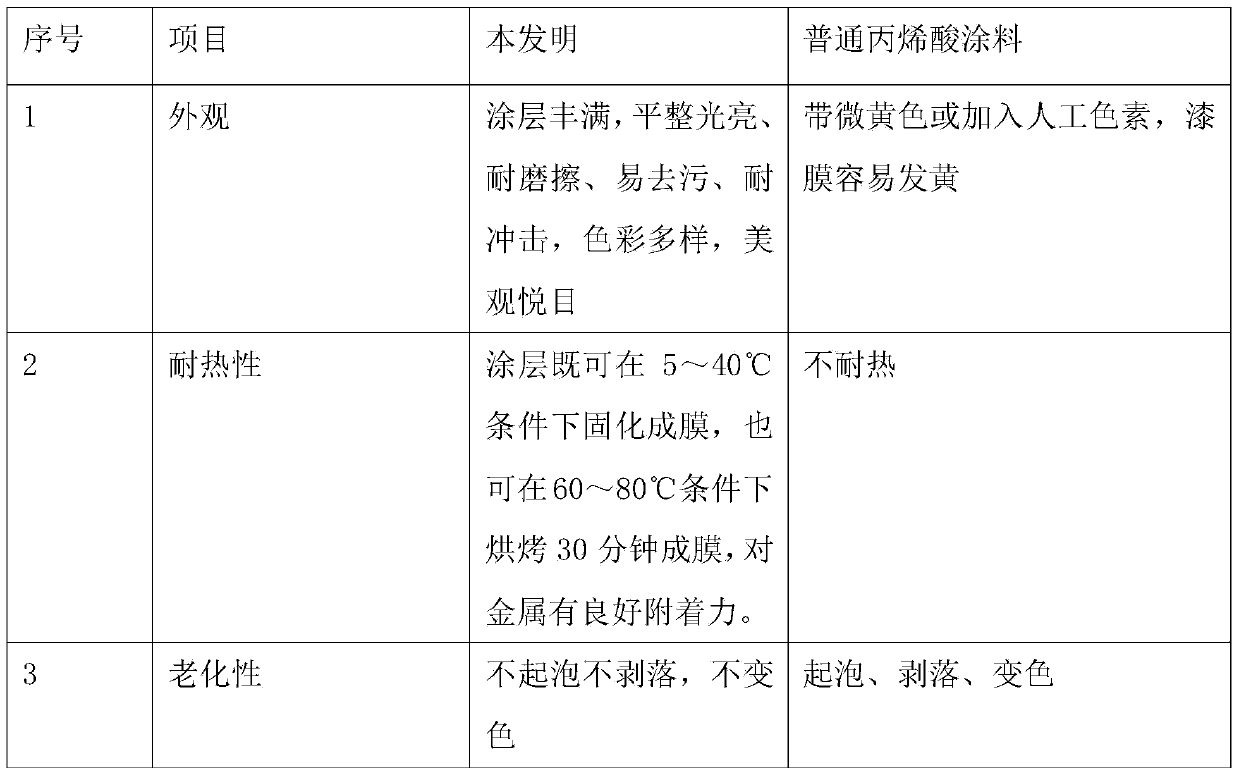

[0011] The main properties of the thermosetting acrylic paint for metal products prepared in this embodiment are as follows.

[0012]

[0013] It shows that the thermosetting acrylic paint for metal products of the present invention has excellent heat resistance and water resistance, good storage stability, goo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com