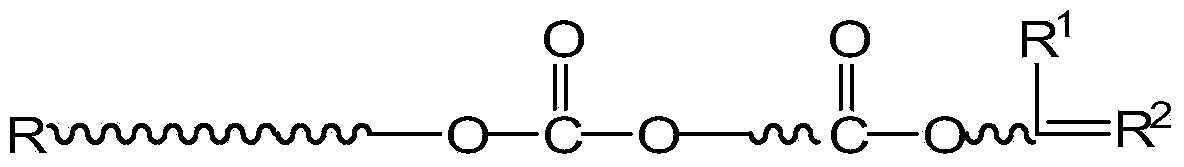

Preparation method of esterified macromer for polycarboxylate water-reducer

A technology of water reducing agent and macromonomer, which is applied in the field of preparation of ester compounds, and can solve the problem that esterified macromonomers do not have polymerization activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

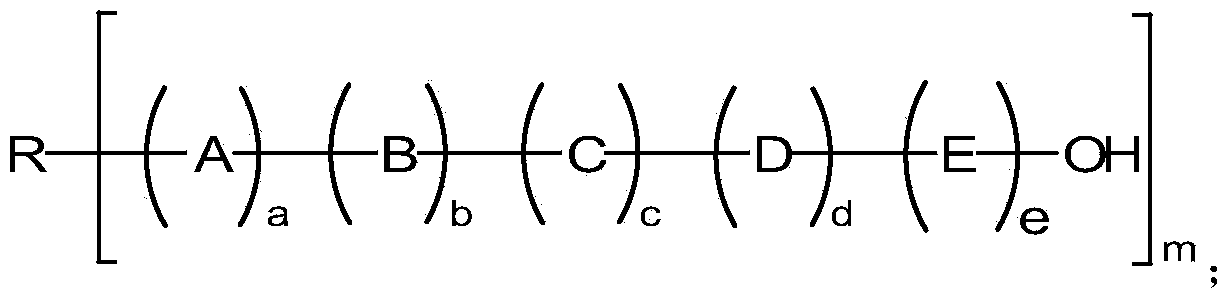

Method used

Image

Examples

Embodiment 1

[0052] Single-ended hydroxyl polyether, the synthetic initiator is methanol, the polymerized monomers are ethylene oxide and glycidyl furfuryl ether, the degree of polymerization of ethylene oxide is 5, the degree of polymerization of glycidyl furfuryl ether is 2, and the number average molecular weight is 560 g / mol. The molar ratio of single-end hydroxyl polyether / acid anhydride / small molecule alcohol is 1:1:0, and the amount of catalyst used is 0% of the mass of polyether. Weigh 1 mol (560 g) of single-terminated hydroxyl polyether and 1 mol of succinic anhydride, add the above-mentioned substances into a closed high-pressure reactor, raise the temperature to 100° C., and keep the temperature for 1 hour. NaOH was added to the reaction system to neutralize it. The volatile matter was removed under reduced pressure, and the insoluble matter was removed by filtration to obtain a polyether intermediate whose terminal group was carboxylate.

[0053] The molar ratio of single-en...

Embodiment 2

[0055] Single-terminated hydroxyl polyether, the synthesis initiator is ethanol, the polymerization monomer is epoxycyclohexane, the degree of polymerization is 20, and the number average molecular weight is 2006g / mol. The molar ratio of single-end hydroxyl polyether / acid anhydride / small molecule alcohol is 1:1.05:0.05, and the amount of catalyst used is 1% of the mass of polyether. Weigh 1 mol (2006 g) of single-terminated hydroxyl polyether, 1.05 mol of phthalic anhydride, and 20.06 g of catalyst p-toluenesulfonic acid. The above-mentioned substances were added into a closed high-pressure reactor, the temperature was raised to 110°C, and the reaction was kept for 2 hours. Then, 0.05 mol of methanol was added into the reactor, and the reaction was continued for 1 h while being kept warm. Add KOH to the reaction system to neutralize it. The volatile matter was removed under reduced pressure, and the insoluble matter was removed by filtration to obtain a polyether intermediat...

Embodiment 3

[0058] Single-terminated hydroxyl polyether, the synthesis initiator is 1-propanol, the polymerization monomer is propylene oxide, the degree of polymerization is 30, and the number average molecular weight is 1800g / mol. The molar ratio of single-end hydroxyl polyether / acid anhydride / small molecule alcohol is 1:1.1:0.1, and the amount of catalyst used is 1.2% of the mass of polyether. Weigh 1 mol (1800 g) of single-terminated hydroxyl polyether, 1.1 mol of formamide succinic anhydride, and 21.6 g of catalyst p-toluenesulfonic acid. Add the above-mentioned substances into a closed high-pressure reactor, raise the temperature to 120°C, and keep the temperature for 2.2 hours. Then, 0.1 mol of 1-propanol was added into the reaction kettle, and the reaction was continued for 1.5 h while keeping the temperature. Add LiOH to the reaction system to neutralize it. The volatile matter was removed under reduced pressure, and the insoluble matter was removed by filtration to obtain a po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com