Implementation method of handheld industrial equipment itinerant detector allowing introduction of inspection path

A technology of inspection path and implementation method, which is applied to the input/output process of instruments, data processing, program control in sequence/logic controllers, etc., and can solve problems such as inability to design inspection path software and lack of intelligent detection functions , to facilitate digital management, improve detection efficiency, and optimize detection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

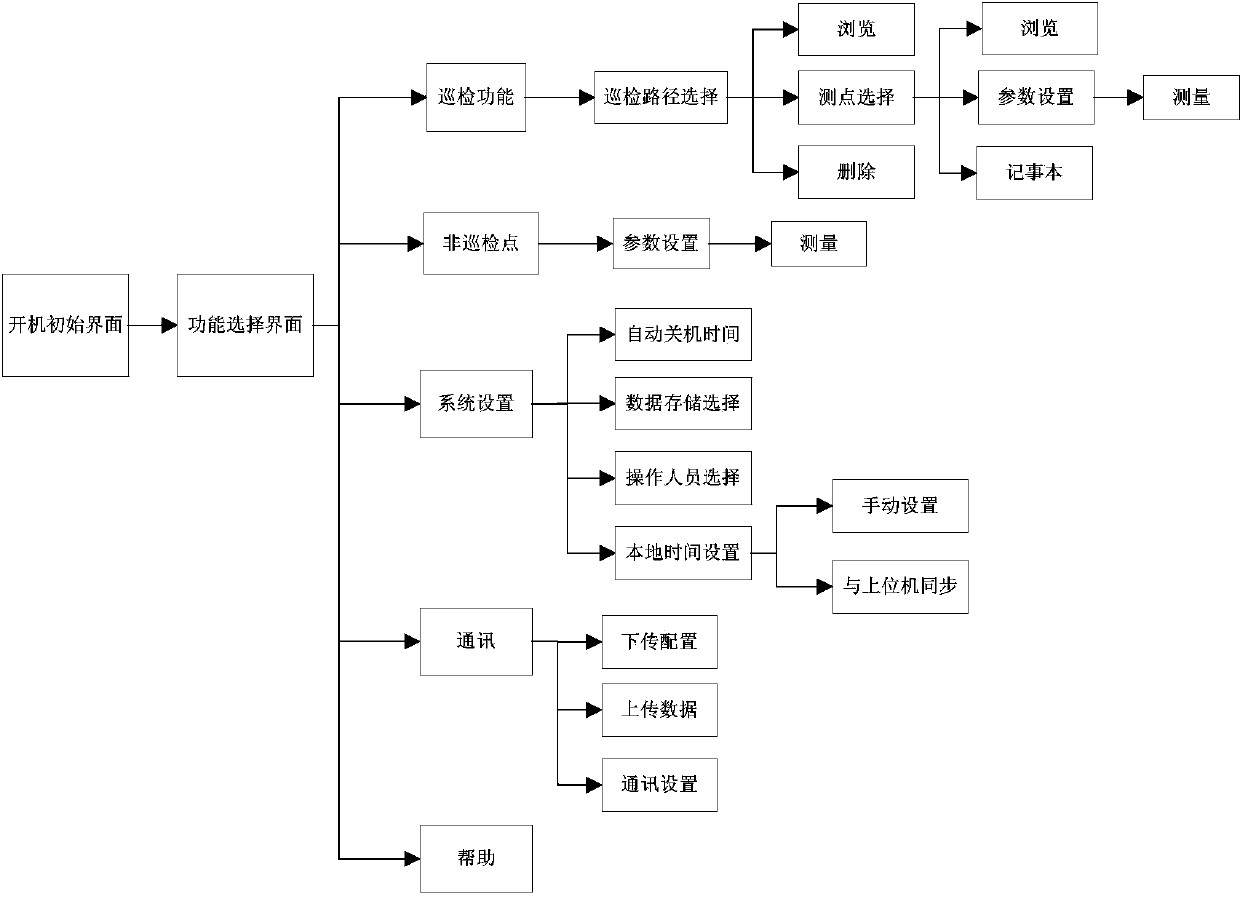

[0041] see figure 1 , Figure 7 .

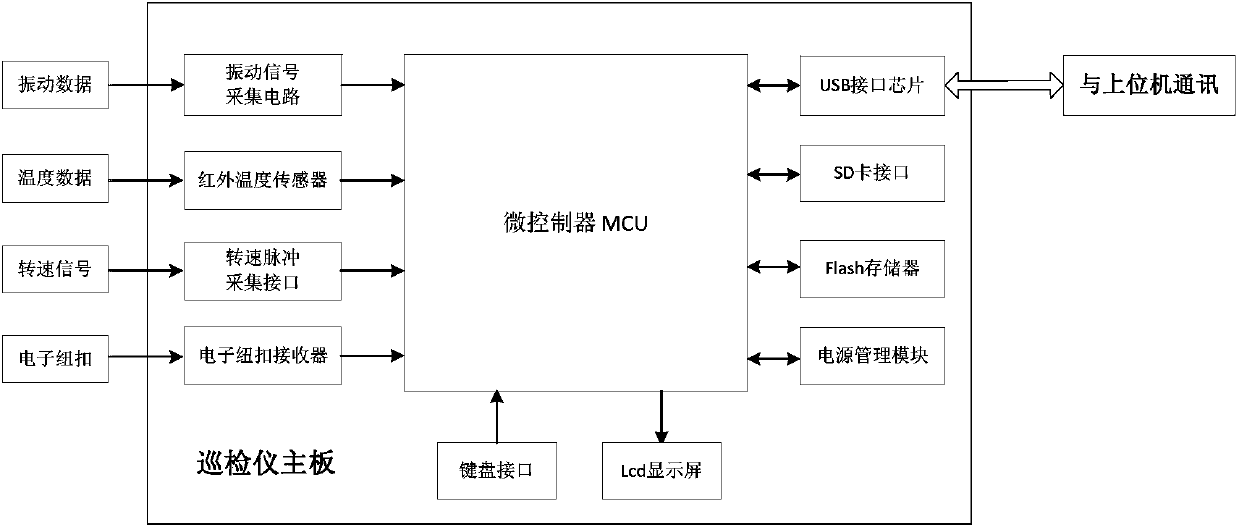

[0042]The inspection instrument used in the present invention is the same as the existing inspection instrument, and has a data processing unit, a signal collector, and a data memory. The data processing unit of the inspection instrument uses the microcontroller MCU as the central control unit, and two types of inspection path mode and non-inspection path mode are set on the microcontroller MCU, and the operator independently determines the mode type according to the needs. A USB interface is set on the periphery of the microcontroller MCU, and the USB interface is used to communicate with the host computer, upload and collect data and send inspection path files.

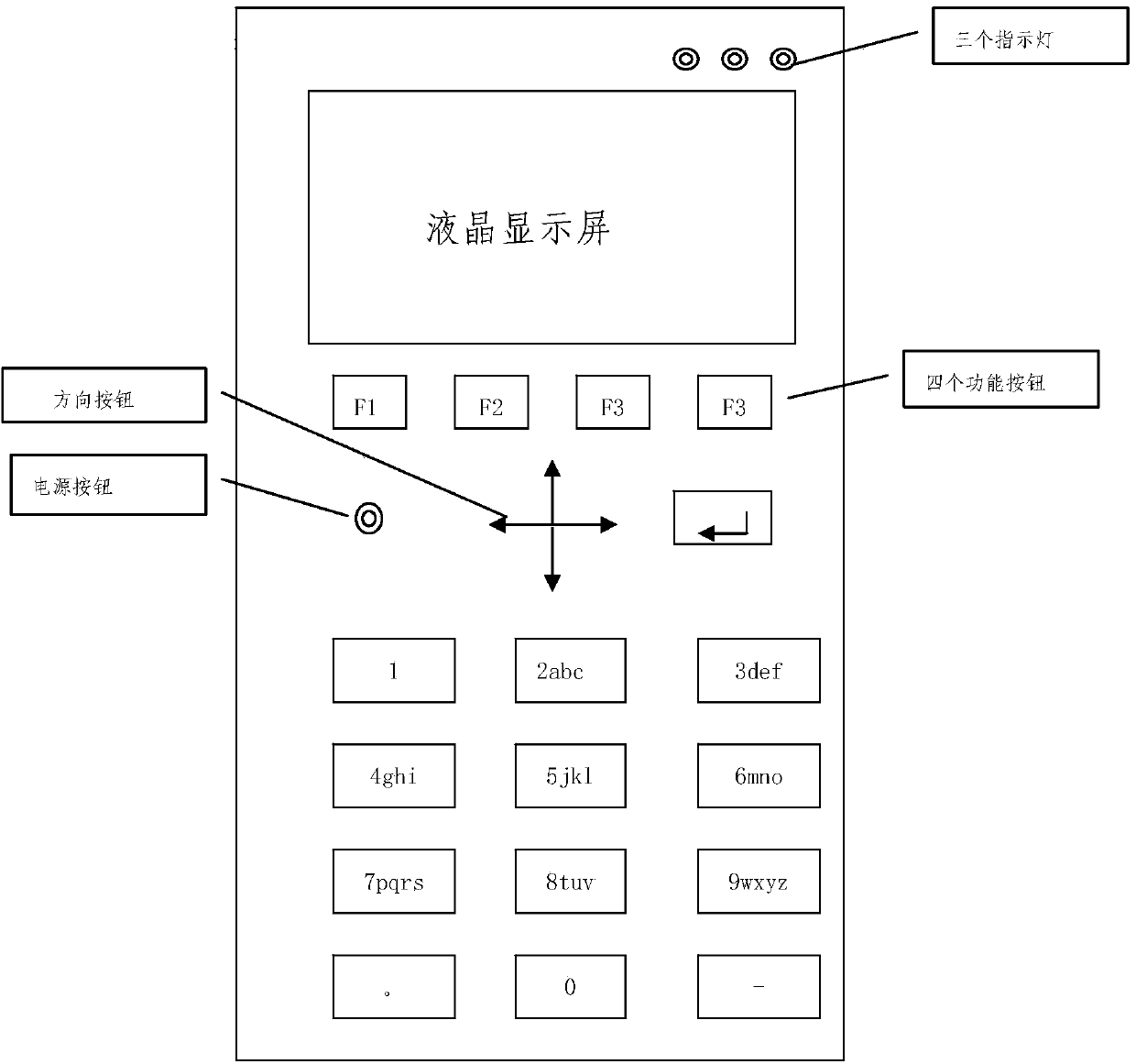

[0043] The inspection instrument adopts the CPU STM32F103Z microcontroller based on ARM cortex M3 core as the central control unit, the operating frequency is 72MHz, and the peripheral expansion has USB interface, SD card interface, flash memory chip, power management module, ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com