Slagging tube of fluidized-bed boiler

A technology of fluidized bed boiler and slag discharge pipe, which is applied in the direction of fluidized bed combustion equipment, fuel burned in molten state, combustion type, etc., can solve the problems of short service life, thermal deformation of slag discharge pipe, tearing weld seam, etc. Achieve the effects of reducing heat dissipation loss, reducing maintenance costs, and saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

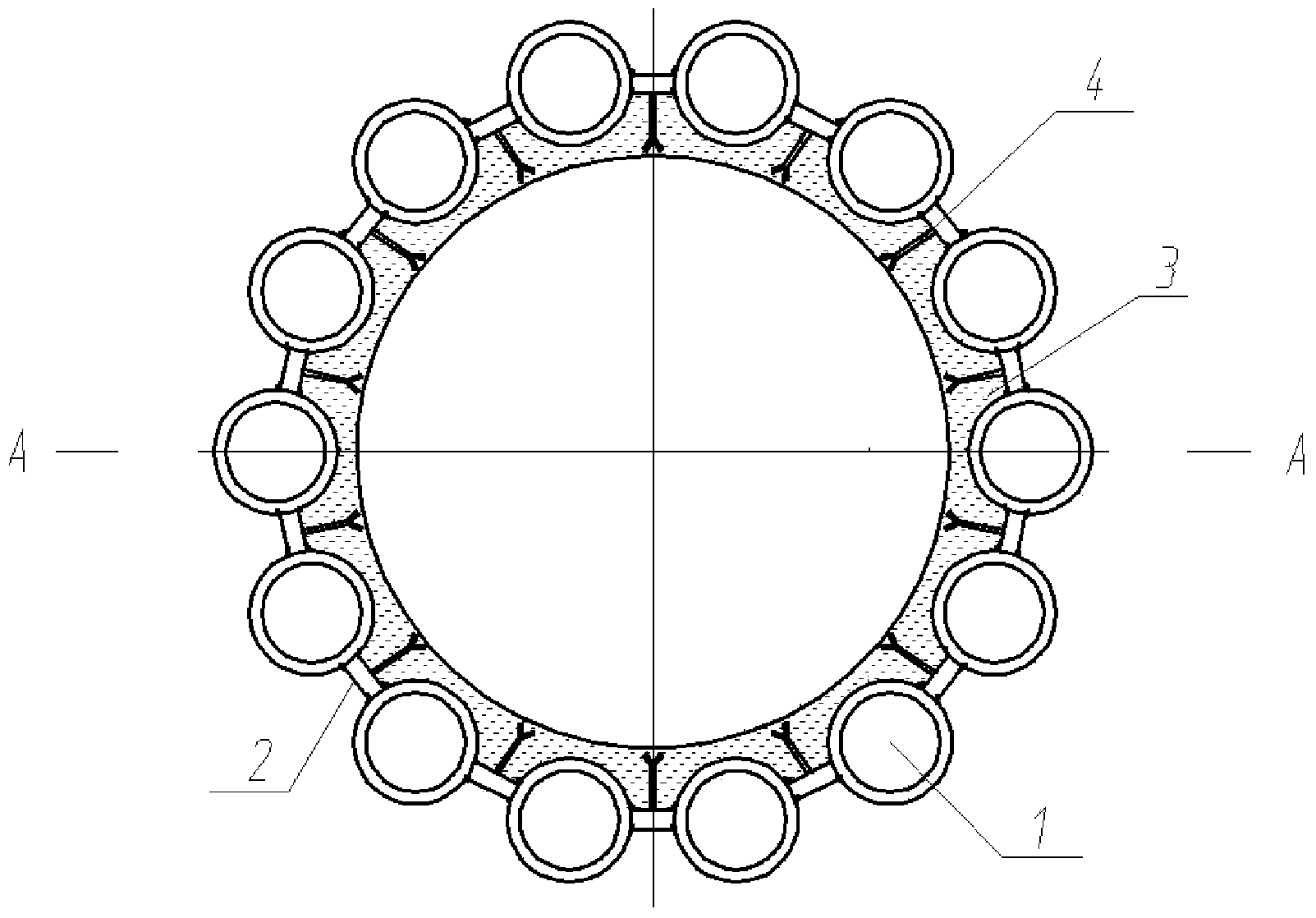

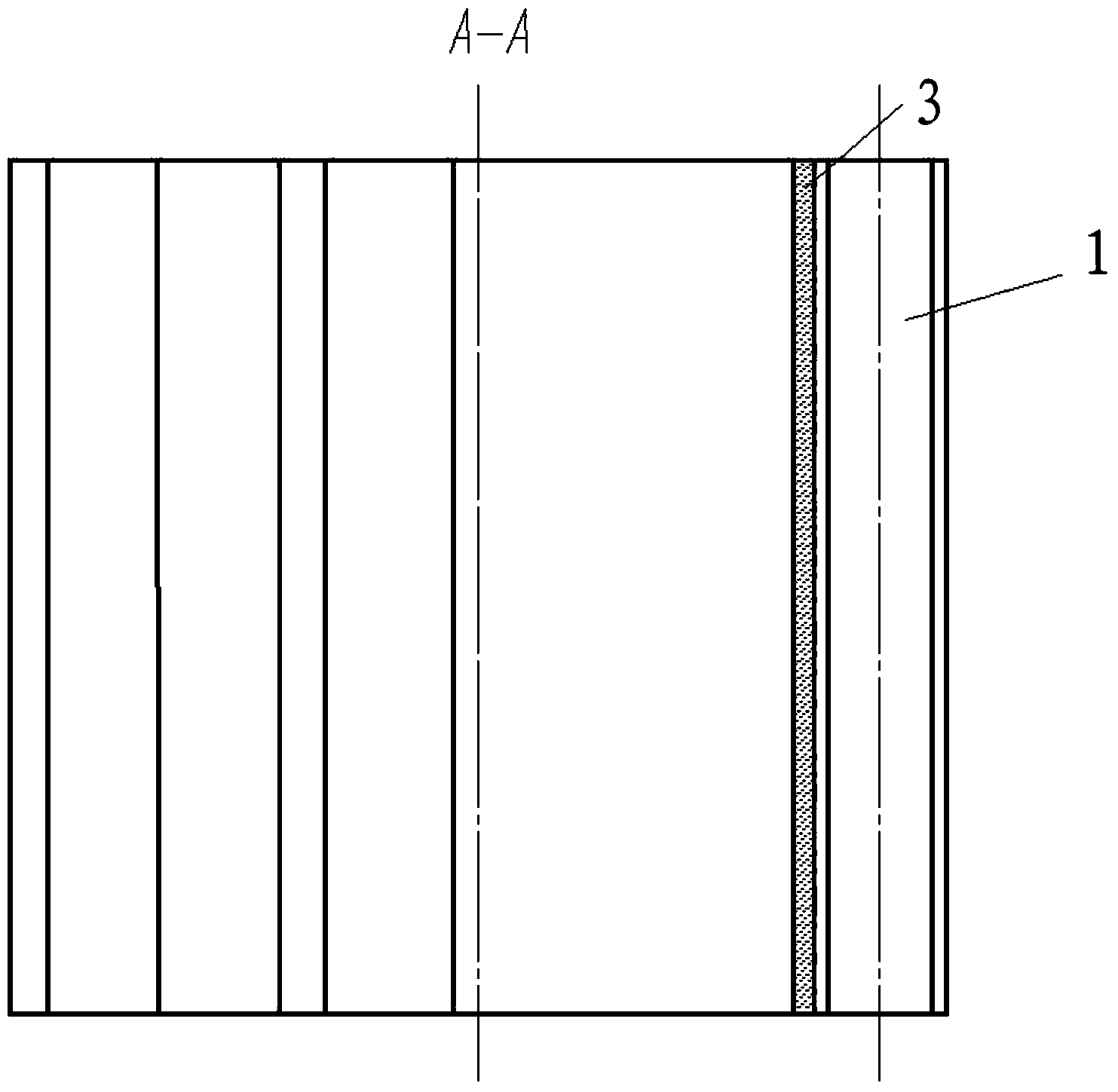

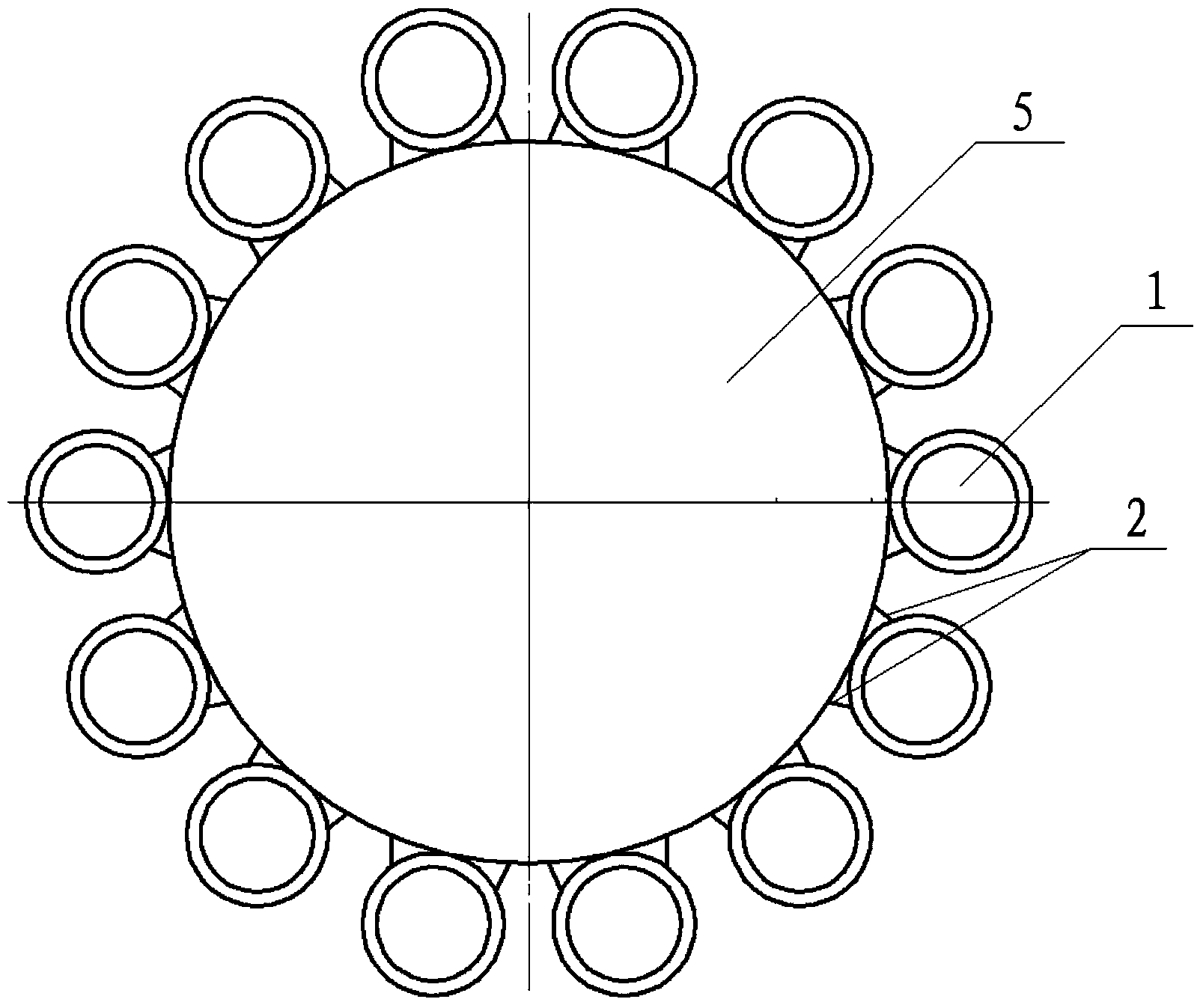

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0024] like figure 1 , 2 As shown in and 4, the first technical solution of the fluidized bed boiler slag discharge pipe of the present invention includes a plurality of cooling pipes 1 to form an annular cooling pipe group. Generally, this structure is called a film cooler, and each cooling pipe 1 adopts a cylindrical Shaped steel pipe or spiral steel pipe. The inner side of the annular cooling tube group is coated with wear-resistant and heat-resistant castable 3; the cooling tube 1 can be made of carbon steel and other materials, and the number of cooling tubes 1 can be reasonably arranged according to the slag amount and slag temperature. The wear-resistant and heat-resistant castable 3 can use materials with wear-resistant and heat-resistant properties such as phosphate and silicon carbide;

[0025] Each cooling pipe 1 is also connected with the jelly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com