Polyamide fiber

A technology of polyamide fibers and polyamides, which is applied in the field of polyamide fibers, can solve the problems such as the dispersion method of boron nitride inorganic particles without any instructions, and achieve good strength and elongation, good thermal conductivity, and effective mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

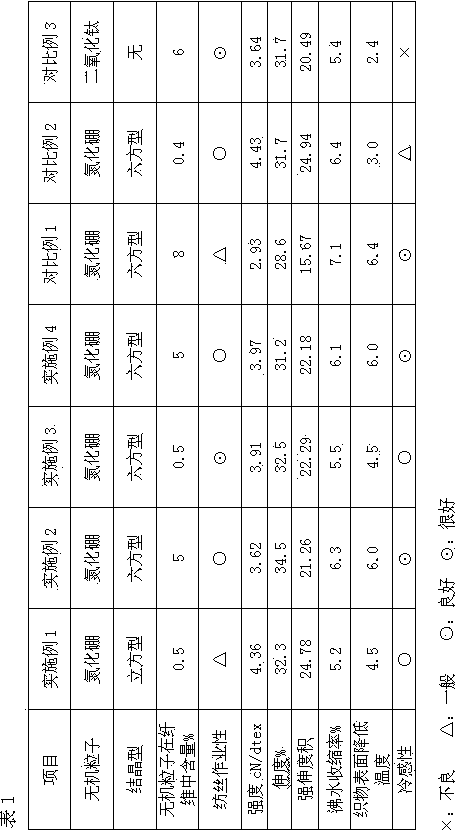

Examples

Embodiment 1

[0040] Dry the nylon 6 slices until the water content is below 300ppm, feed the masterbatch containing 20% cubic boron nitride inorganic particles into the small silo, set the masterbatch addition amount to 2.5wt%, and enter the screw extrusion after being mixed by the mixer The inlet of the machine is melted in the screw extruder, and the discharge volume is controlled by the metering pump. The primary fiber is spun through the spinning assembly under the temperature control of the spinning box, cooled and solidified under the side blowing, and then passed through the oil nozzle. Oil the fibers evenly to bundle them and reduce friction. The fibers that have been oiled and bundled pass through the spinning shaft, enter the first roller (1GR), and then enter the coiler after being wound around the second roller (2GR) to obtain pre-oriented yarn POY.

[0041] The obtained pre-oriented yarn POY is processed on a false twisting machine, and the false twisted yarn DTY monofilamen...

Embodiment 2

[0043] Dry the nylon 6 slices until the water content is below 300ppm, feed the masterbatch containing 20% hexagonal boron nitride inorganic particles into the small silo, set the masterbatch addition to 25wt%, and enter the screw extruder after being mixed by the mixer Imported, melted in the screw extruder, the discharge volume is controlled by the metering pump, the primary fiber is spun through the spinning assembly under the temperature control of the spinning box, cooled and solidified under the side blowing, and then passed through the oil nozzle The fibers are evenly oiled to bundle the fibers and reduce friction. The fibers that have been oiled and bundled pass through the spinning shaft, enter the first roller (1GR), and then enter the coiler after being wound around the second roller (2GR) to obtain pre-oriented yarn POY.

[0044]The obtained pre-oriented yarn POY is processed on a false twisting machine. The monofilament fineness of the false twisted yarn DTY is ...

Embodiment 3

[0046] Dry the nylon 6 slices until the water content is less than 300ppm, feed the masterbatch containing 20% hexagonal boron nitride inorganic particles into the small silo, set the masterbatch addition to 2.5wt%, and enter the screw extrusion after being mixed by the mixer The inlet of the screw extruder is melted in the screw extruder, and the discharge volume is controlled by the metering pump. The primary fiber is spun through the spinning assembly under the temperature control of the spinning box, cooled and solidified under the condition of side blowing, and then fed The oil nozzle evenly oils the fibers to bundle the fibers and reduce friction. The fibers that have been oiled and bundled pass through the spinning shaft, are entangled by the pre-interlacer, enter the first hot roll 1HR, and are wound on the first hot roll for 6~7 laps, and then pass through the second hot roll 2HR. Wrap 6~7 laps on it, and the stretched fiber between the first hot roller and the seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Monofilament denier | aaaaa | aaaaa |

| Average dispersed particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com