Method for preparing terpeneless dementholized peppermint oil through azeotropic distillation

A technology of peppermint oil and azeotropic distillation, applied in the direction of essential oil/spice, fat oil/fat refining, fat production, etc., can solve the problems of azeotropic distillation research literature and patents, etc., and achieve rich specifications and low system requirements , to avoid the effect of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This embodiment relates to a method for preparing terpene-free peppermint oil by azeotropic distillation, comprising the following steps:

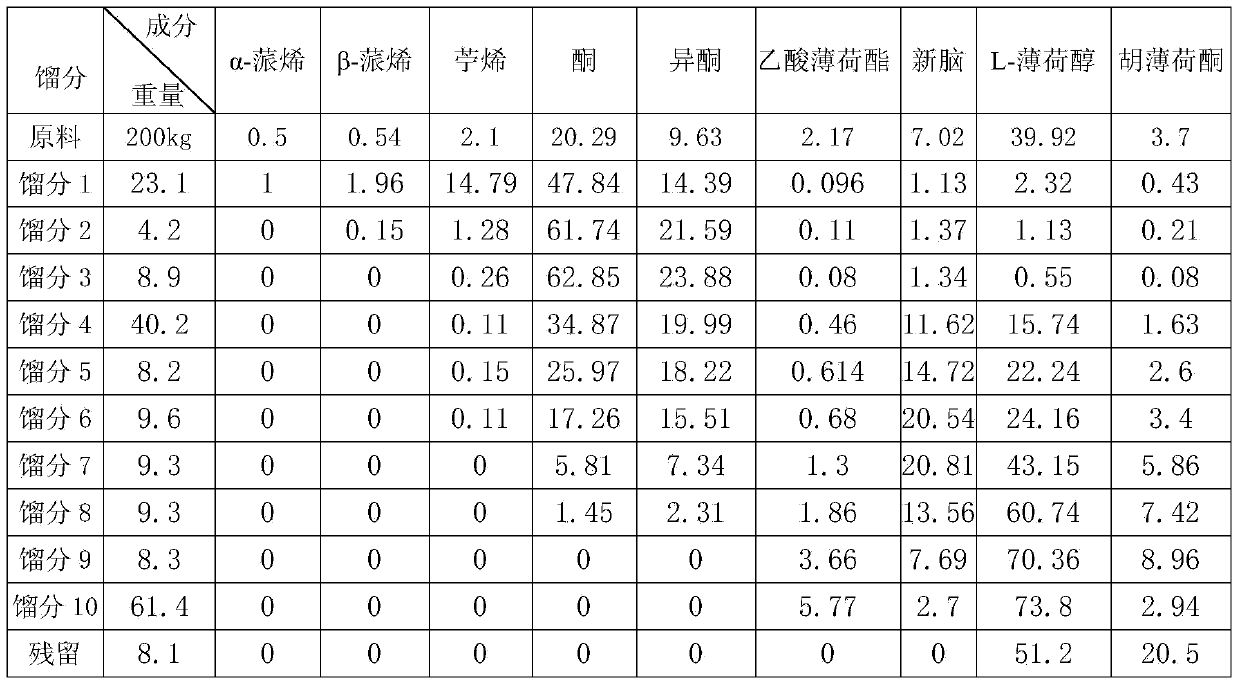

[0022] Step (1), under 0.095MPa, pump 200kg of peppermint oil into a rectification still equipped with a stainless steel θ ring rectification column (column diameter 0.25m, height 2m), the theoretical tray of the packing is 80, add a total of Boiling agent ethylene glycol 10kg, under the condition of temperature 40°C and reflux ratio of 1:1, receive cuts in sections (the main components of each cut are shown in Table 1), and stop rectification when basically no cuts flow out;

[0023] Step (2), after the fraction is washed with water to separate the entrainer, select a suitable fraction for deployment (the fraction used to prepare the terpene-free oil is shown in Table 2), and obtain the terpene-free mint oil (the content of its main components is shown in Table 3. shown).

[0024] Table 1 Main components of azeotropic distillation...

Embodiment 2

[0031] This embodiment relates to a method for preparing terpene-free peppermint oil by azeotropic distillation, comprising the following steps:

[0032] Step (1), under 0.04MPa, pump 200kg of mint oil into a rectification still equipped with a glass packing rectification column (column diameter 0.25m, height 0.4m), the theoretical plate of the packing is 10, add Entrainer ethanol 100kg, at temperature 75 DEG C, reflux ratio is 3:1 condition, section receives cut (the main component of each cut is as shown in Table 4), when substantially no cut flows out, stop rectification;

[0033] Step (2), after the fraction is washed with water to separate the entrainer, select a suitable fraction for deployment (the fraction used to prepare the terpene-free oil is shown in Table 5), and obtain the terpene-free mint oil (the content of its main components is shown in Table 6) shown).

[0034] Table 4 Main components of azeotropic distillation fraction

[0035]

[0036] Table 5 is use...

Embodiment 3

[0041] This embodiment relates to a method for preparing terpene-free peppermint oil by azeotropic distillation, comprising the following steps:

[0042] Step (1), under 0.065MPa, 200kg of mint oil is pumped into the rectification still equipped with triangular spiral packing rectification column (column diameter 0.25m, high 4m), the theoretical plate of packing is 50, add a total of Boiling agent glycerin 50kg, propylene glycol 50kg, under the condition of temperature being 110 DEG C, reflux ratio 20:1, receiving cuts in sections (the main components of each cut are shown in Table 7), when basically no cuts flow out, stop the rectification;

[0043] Step (2), after the fraction is washed with water to separate the entrainer, select a suitable fraction for deployment (the fraction used to prepare the terpene-free oil is shown in Table 8) to obtain the terpene-free mint oil (the content of its main components is shown in Table 9) shown).

[0044] Table 7 Main components of aze...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com