Spray packing tower for flue gas waste heat recovery

A technology of spraying packing and waste heat of flue gas is applied in the field of spraying and packing tower, which can solve the problems of serious corrosion of heat exchange between flue gas and refrigerant, low utilization efficiency of waste heat of spray cooling water, instability of waste heat utilization of the system, etc. Achieve excellent energy-saving benefits, increase the contact heat exchange area and contact time, and reduce the effect of spray water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

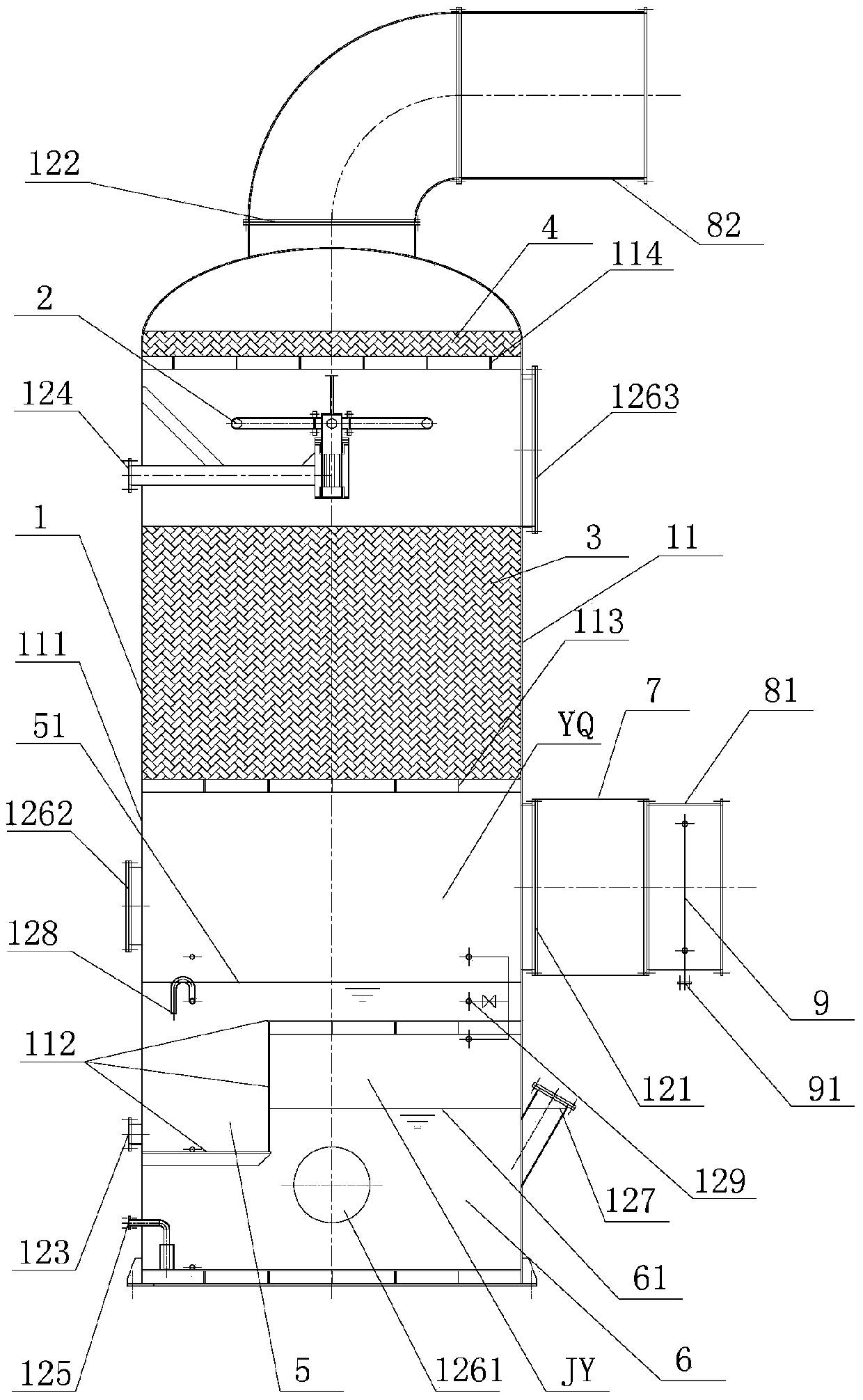

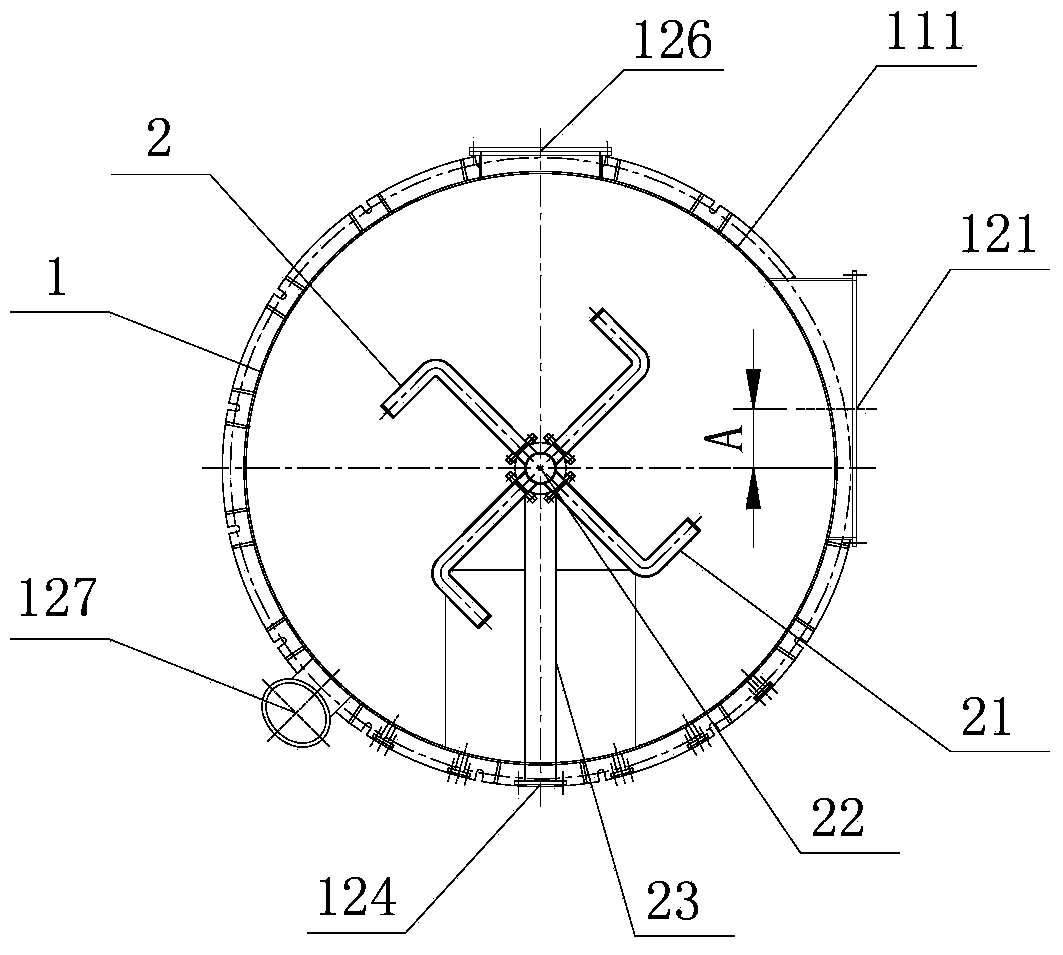

[0030] Such as figure 1 and figure 2 As shown, the present invention proposes a spray packing tower for flue gas waste heat recovery, which is characterized in that the spray packing tower for flue gas waste heat recovery includes: a spray packing tower main body 1, a spray assembly 2 , filler 3, water eliminator 4, fan 7, flue gas pipeline and oxidant distributor 9, among which:

[0031] The main body 1 of the spray packed tower comprises: the main body structural member 11 of the spray packed tower composed of the outer casing 111 of the spray packed tower, the middle partition plate 112 of the spray packed tower, the packing support plate 113 and the water eliminator support plate 114, and The main body interface of the spray packed tower arranged on the main structure part 11 of the spray packed tower;

[0032] The main interface of the spray packing tower includes: flue gas inlet 121, flue gas outlet 122, spray circulating water outlet 123, spray circulating water inle...

Embodiment 2

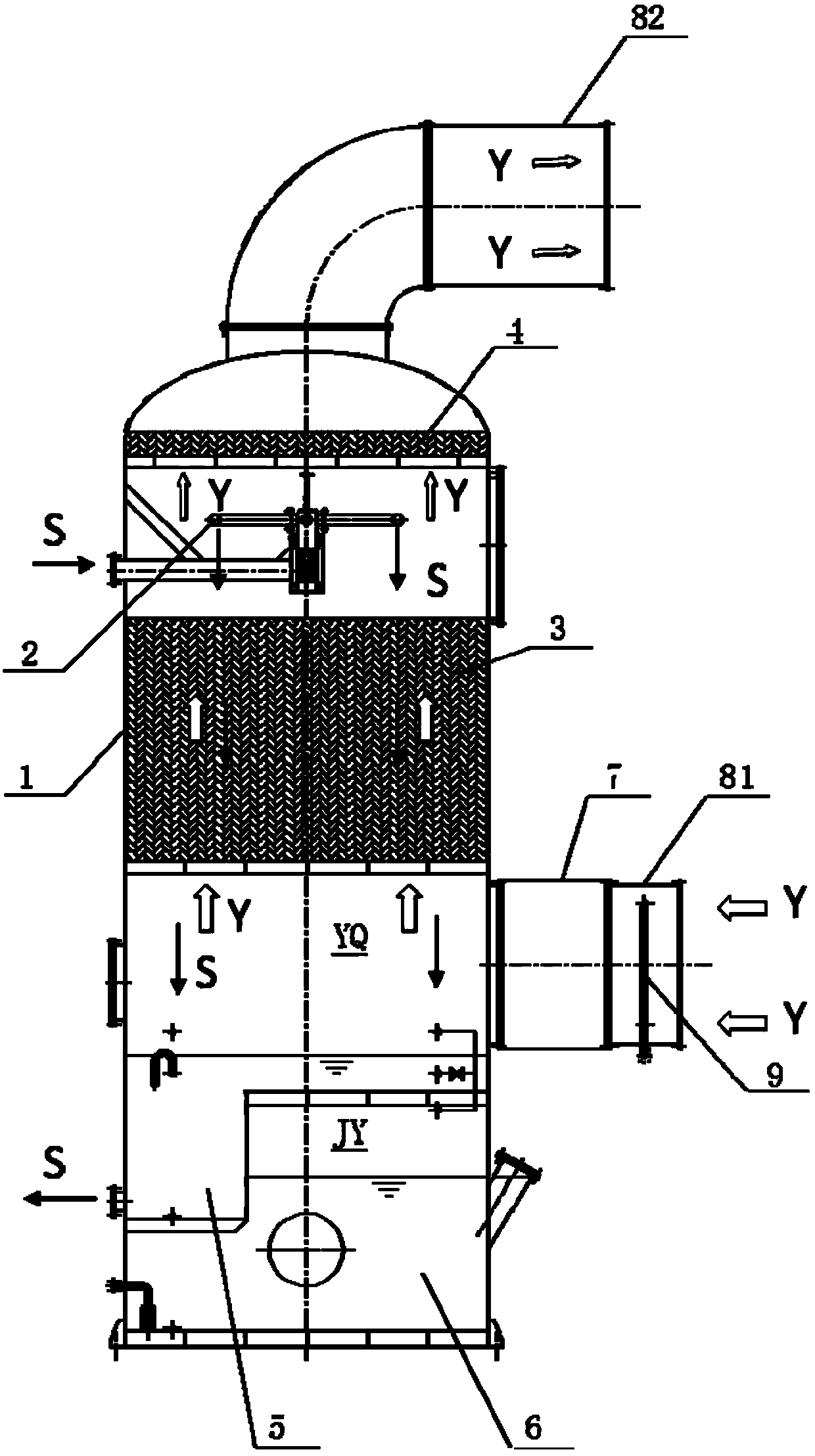

[0052] Figure 4 It is a schematic structural diagram of a spray-packed tower for flue gas waste heat recovery according to Embodiment 2 of the present invention. The difference between the second embodiment and the first embodiment is that the fan 7 of the first embodiment is connected with the pipe 81 where the flue gas enters the spray packed tower, while the fan 7 of the second embodiment is connected with the pipe 81 where the flue gas goes out of the spray packed tower 82 are connected. The temperature of the transported flue gas in the fan 7 of the first embodiment is relatively high but the flue gas has not yet reached saturation. The advantage is that the transported flue gas does not condense and has less corrosion. The efficiency will be reduced, and the high temperature will also bring some heat dissipation problems to the equipment that need to be considered. The temperature of the transported flue gas in the fan 7 of the second embodiment is relatively low but ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com