Demulsification column, and apparatus using demulsification column and capable of realizing on-line automatic demulsification during extraction

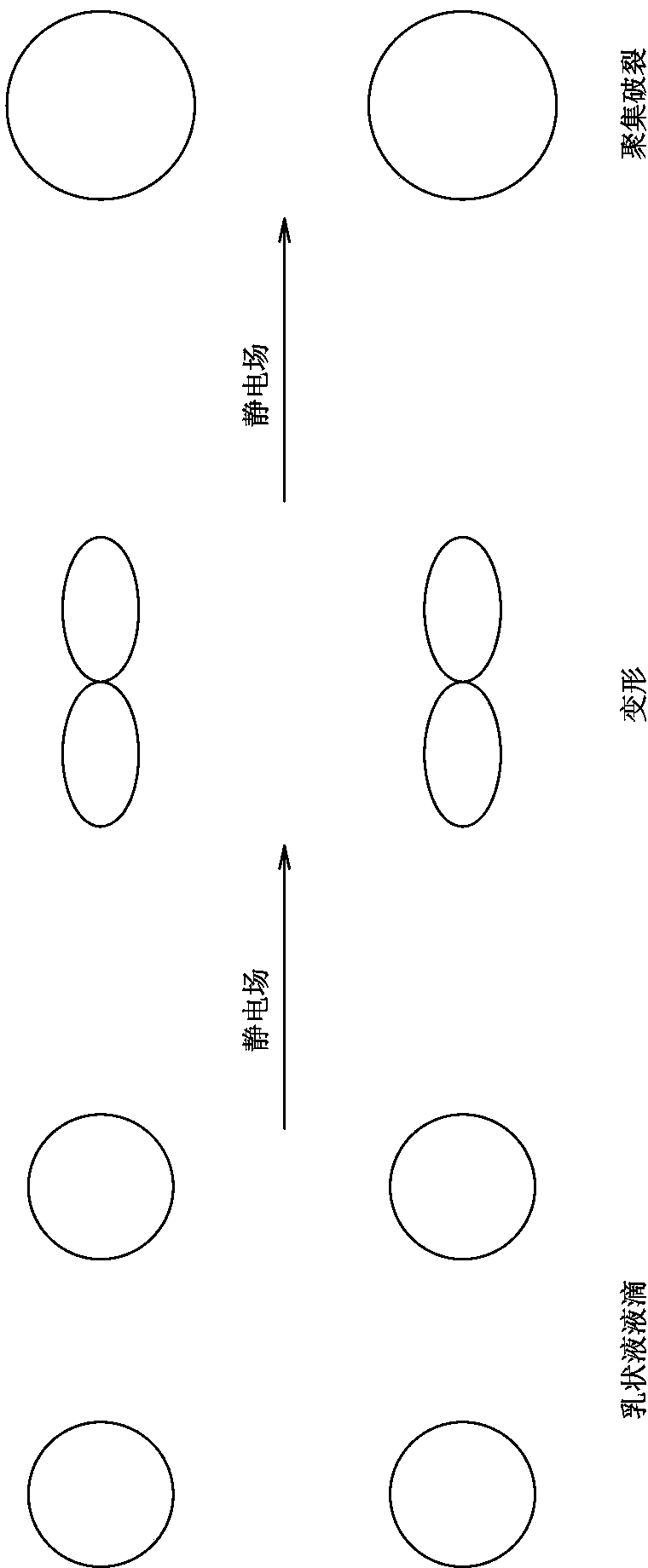

A milk column and demulsification technology, which is applied in the direction of solvent extraction of liquid solution, separation of immiscible liquid, separation of liquid by electricity, etc., can solve the problems of extraction efficiency and accuracy of detection results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

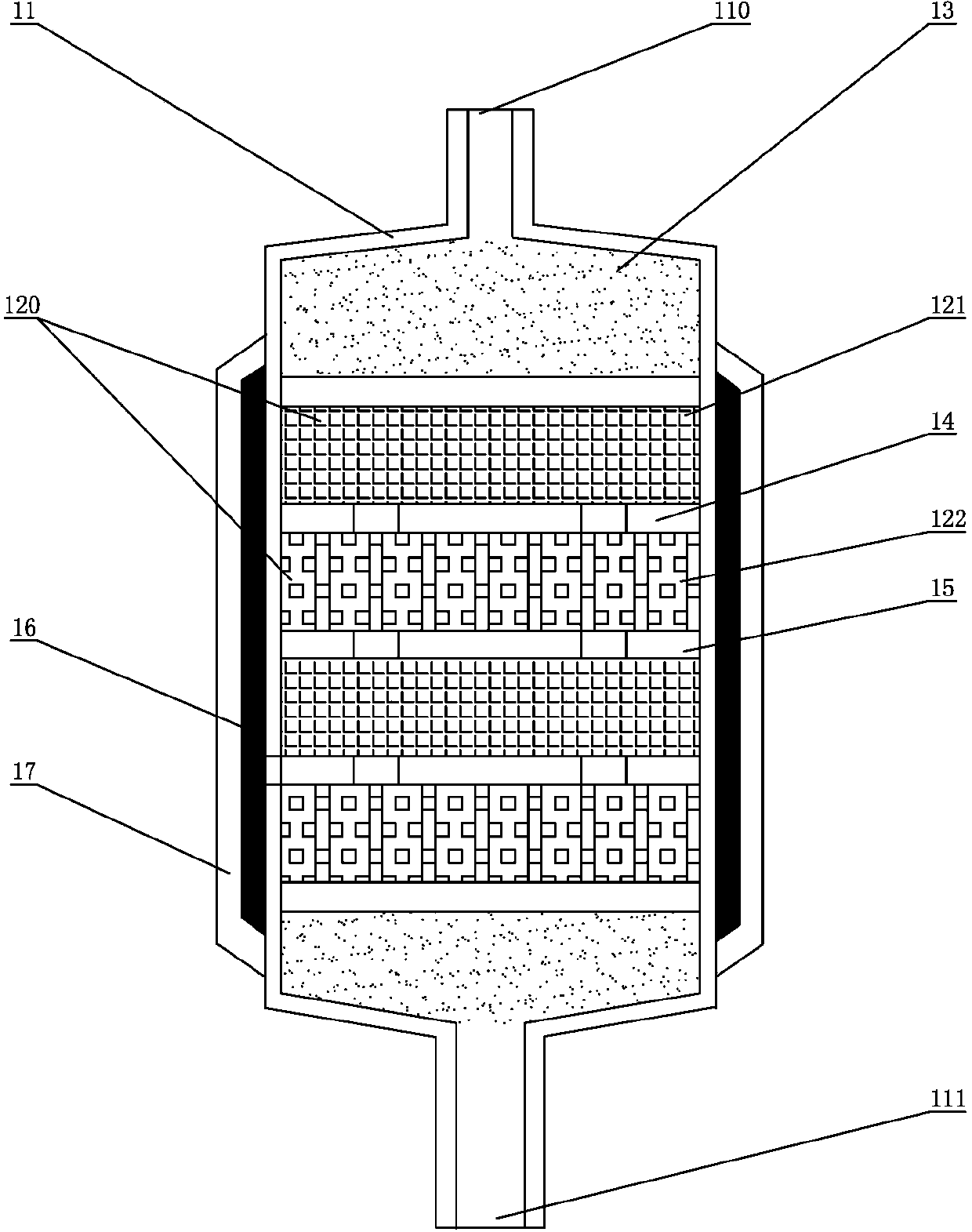

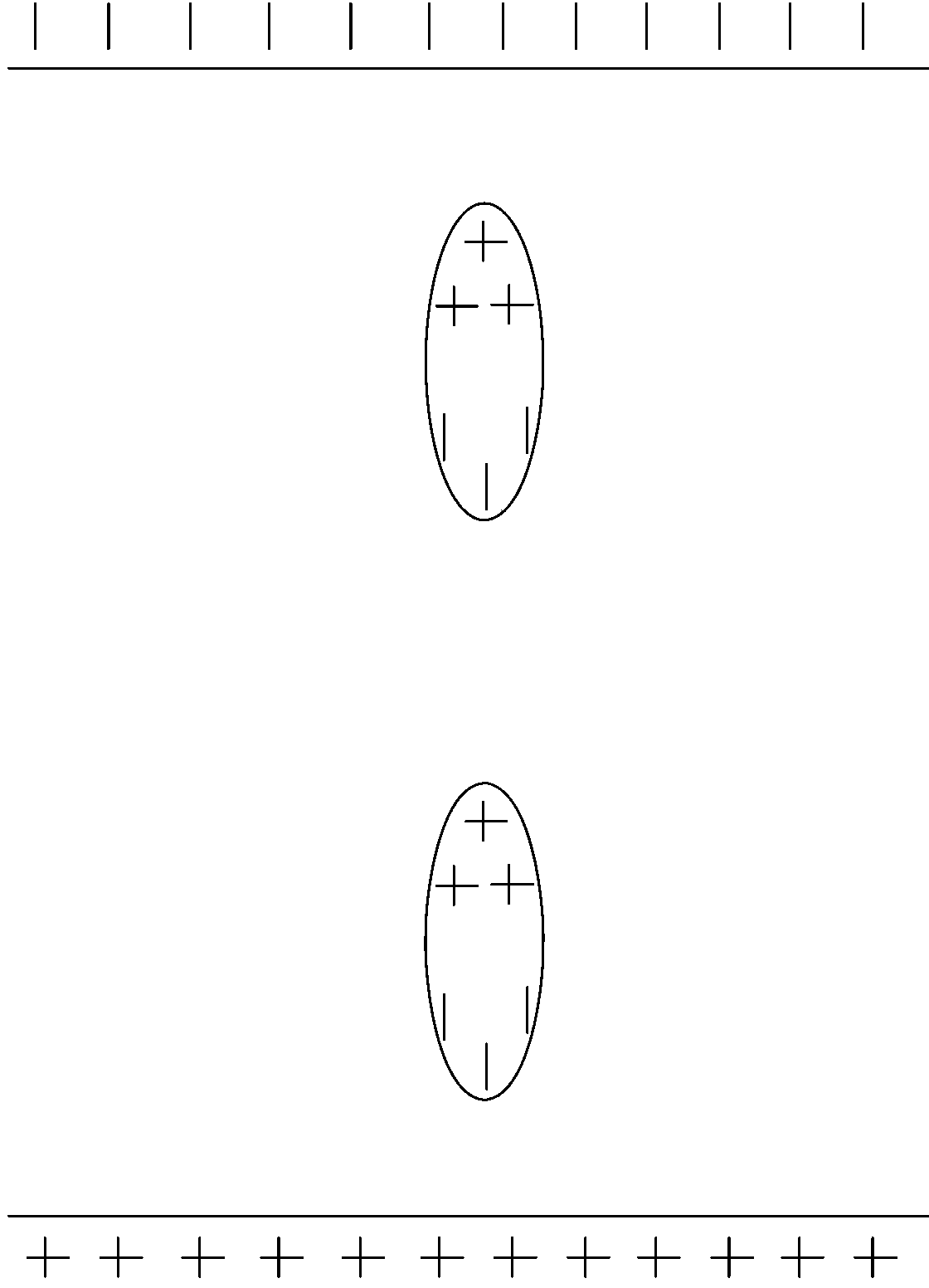

[0024] Such as figure 1 As shown, a demulsification column includes an insulating casing 11 and a primary battery 120 arranged in the insulating casing 11, the primary battery includes a positive electrode 121 of a primary battery and a negative electrode 122 of a primary battery, and the positive electrode 121 of the primary battery is a foam copper, and the negative electrode 122 of the primary battery is nickel foam. The two ends of the insulating shell 11 are provided with a first opening 110 and a second opening 111, and the demulsification column also includes an opening disposed in the insulating shell 11 close to the first opening 110 and the second opening 111. The filter mat 13 , the electret 16 wrapped on the insulating shell 11 and the envelope 17 wrapped outside the electret 16 . A first insulating support 14 is provided between the positive electrode 121 of the primary battery and the negative electrode 122 of the primary battery. The primary battery 120 is divi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com