Concentrated feed for piglets and processing method thereof

A technology for concentrated feed and piglets, which is applied in the field of concentrated feed for piglets and its processing, can solve the problems of poor resistance to bacteria and environmental changes, insufficient physiological functions of piglets, and incomplete immunity of the body, etc. The effect of palatability, guaranteed daily weight gain, and guaranteed feed intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

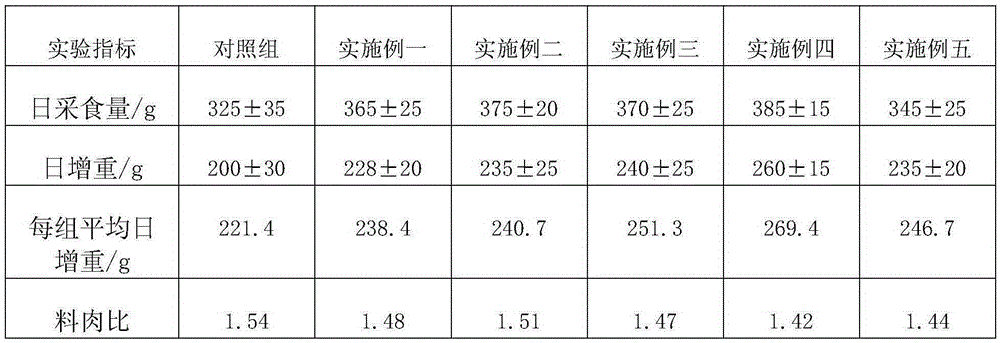

Examples

Embodiment 1

[0020] A concentrated feed for piglets, which is composed of the following raw materials in weight ratio: 15 parts of full-fat puffed soybeans, 10 parts of fermented soybean meal, 20 parts of puffed soybean meal, 10 parts of Peruvian super fish meal (cp67%), 8 parts of flour, and first-grade soybean oil 1.5 parts, 5 parts of premix, premix includes 0.5 parts of lactose, 1.5 parts of glucose, 3 parts of calcium powder, 0.5 parts of choline chloride, 5 parts of 98.5% lysine, 1 part of methionine, 1.5 parts of threonine , 1.5 parts of flavoring agent, 4.5 parts of ethoxyquinoline, 4.5 parts of acidifier, 6 parts of vitamins for suckling pigs, 1 part of trace elements for suckling pigs, 6 parts of sesame oil residue cake, 10 parts of ginkgo leaf powder, 5 parts of chestnut kernel powder 10 parts of peanut kernel powder, 10 parts of sweet potato powder, 5 parts of sweet potato vine, 20 parts of sweet potato leaf powder, 6 parts of potato powder, 6 parts of pig sprouts, 3 parts of pl...

Embodiment 2

[0026]A concentrated feed for piglets, consisting of the following raw materials in weight ratio: 30 parts of full-fat puffed soybeans, 20 parts of fermented soybean meal, 25 parts of puffed soybean meal, 20 parts of Peruvian super fishmeal, 15 parts of flour, 5 parts of first-grade soybean oil, 15 parts of mixed material, premixed material including 3.5 parts of lactose, 5 parts of glucose, 8 parts of calcium powder, 6.5 parts of choline chloride, 10.5 parts of 98.5% lysine, 6 parts of methionine, 5 parts of threonine, 6.5 parts of flavoring agent 8.5 parts of ethoxyquinoline, 10 parts of acidifier, 12 parts of vitamins for suckling pigs, 5 parts of trace elements for suckling pigs, 15 parts of sesame oil residue cake, 20 parts of ginkgo leaf powder, 7.5 parts of chestnut kernel powder, peanut kernels 15 parts of rice flour, 20 parts of sweet potato powder, 7.5 parts of sweet potato vine, 30 parts of sweet potato leaf powder, 15 parts of potato powder, 10 parts of pig sprouts,...

Embodiment 3

[0032] A concentrated feed for piglets, consisting of the following raw materials in weight proportions: 18 parts of full-fat puffed soybeans, 15 parts of fermented soybean meal, 22 parts of puffed soybean meal, 15 parts of Peruvian super fish meal, 12 parts of flour, 3 parts of first-grade soybean oil, pre- 10 parts of mixed material, premixed material including 2 parts of lactose, 3 parts of glucose, 5.5 parts of calcium powder, 3.5 parts of choline chloride, 7.5 parts of 98.5% lysine, 3.5 parts of methionine, 3 parts of threonine, 4 parts of fragrance 6.5 parts of ethoxyquinoline, 6 parts of acidifier, 9 parts of vitamins for suckling pigs, 3 parts of trace elements for suckling pigs, 10.5 parts of sesame oil residue cake, 15 parts of ginkgo leaf powder, 6.5 parts of chestnut kernel powder, peanut kernels 12 parts of rice flour, 15 parts of sweet potato powder, 6 parts of sweet potato vine, 25 parts of sweet potato leaf powder, 10.5 parts of potato flour, 8 parts of pig spro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com