Line leak detector and method of using same

A detector, pipeline technology, applied in the field of leak detection, which can solve the problems of increasing customer dissatisfaction, slow fuel, increasing dispensing time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

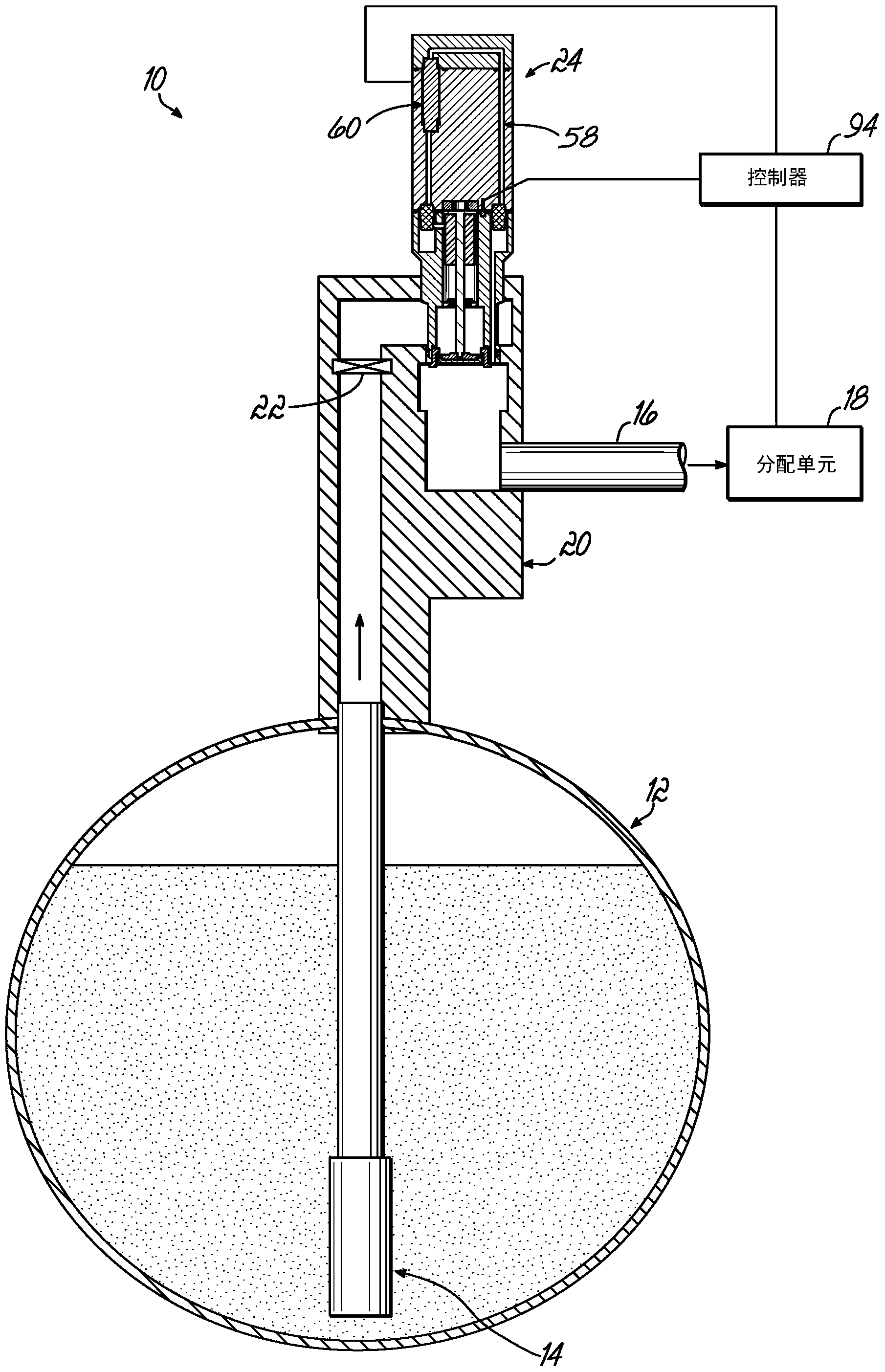

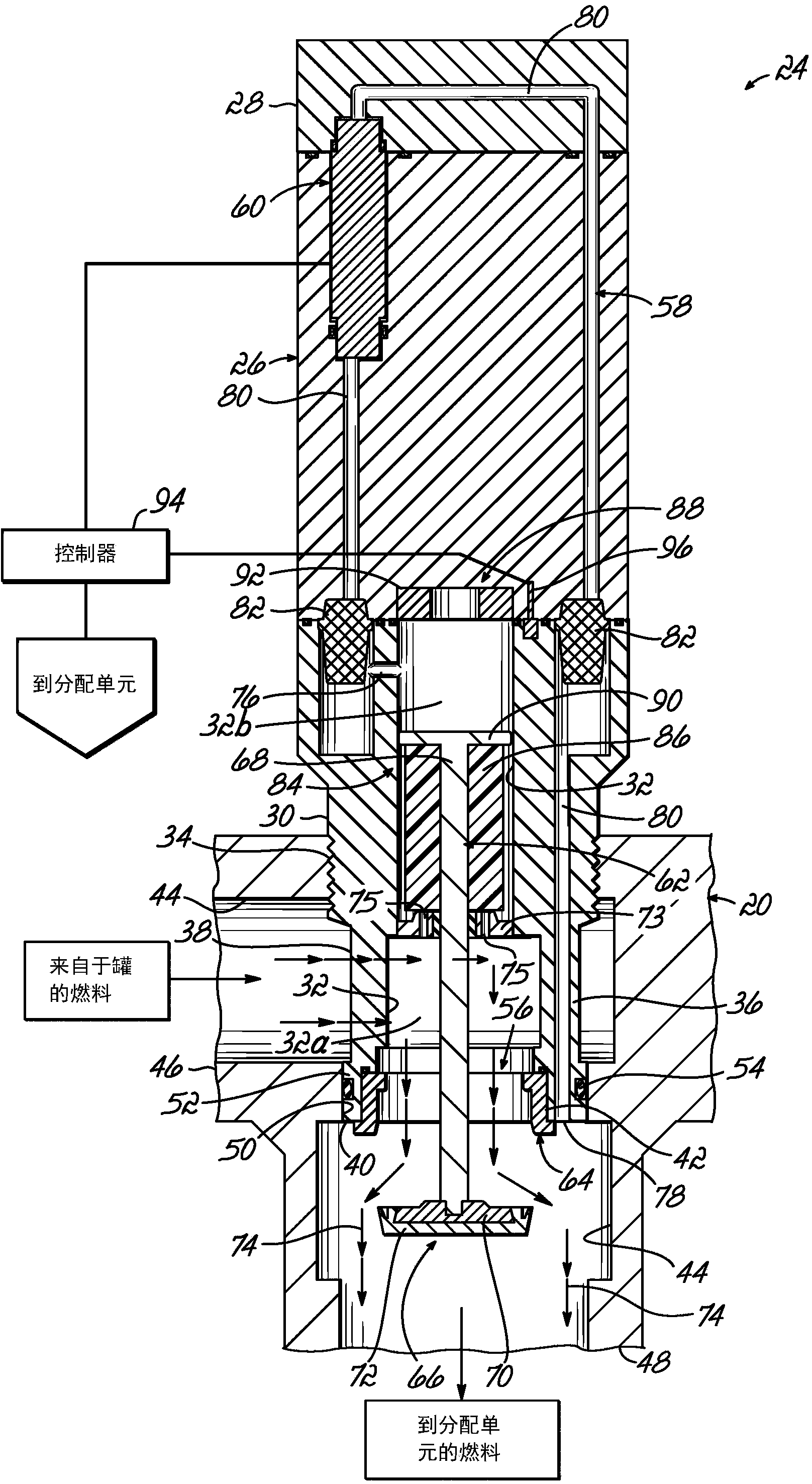

[0024] figure 1An exemplary fuel dispensing system 10 according to an embodiment of the present invention is shown in , and generally includes an underground storage tank ("UST") 12 for storing fuel, an immersion pump 14 located in the tank 12, and pressurized fuel The fluid conduit line 16 delivered to one or more distribution units 18, the one or more distribution units 18 in figure 1 is schematically shown in . Typically, fluid conduit line 16 is coupled to immersion pump 14 via a pump manifold 20, which is typically located outside tank 12, such as in a covered walkway (not shown). The pump manifold 20 may include a check valve 22 for preventing fuel from flowing back into the tank 12 . Since the check valve 22 prevents any fuel from flowing back into the tank 12 when the dispensing unit 18 is closed or closed thereby preventing fuel from flowing from the conduit line 16, the fluid conduit line 16 defines a closed system containing a quantity or volume of fuel , the clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com