Servo motor with encoder function and position detection method of servo motor with encoder function

A technology of a servo motor and a detection method, applied in the field of servo motor research, can solve the problems that cannot be overcome at the same time, and achieve the effects of improving structural strength and reliability, simplifying protective structure and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

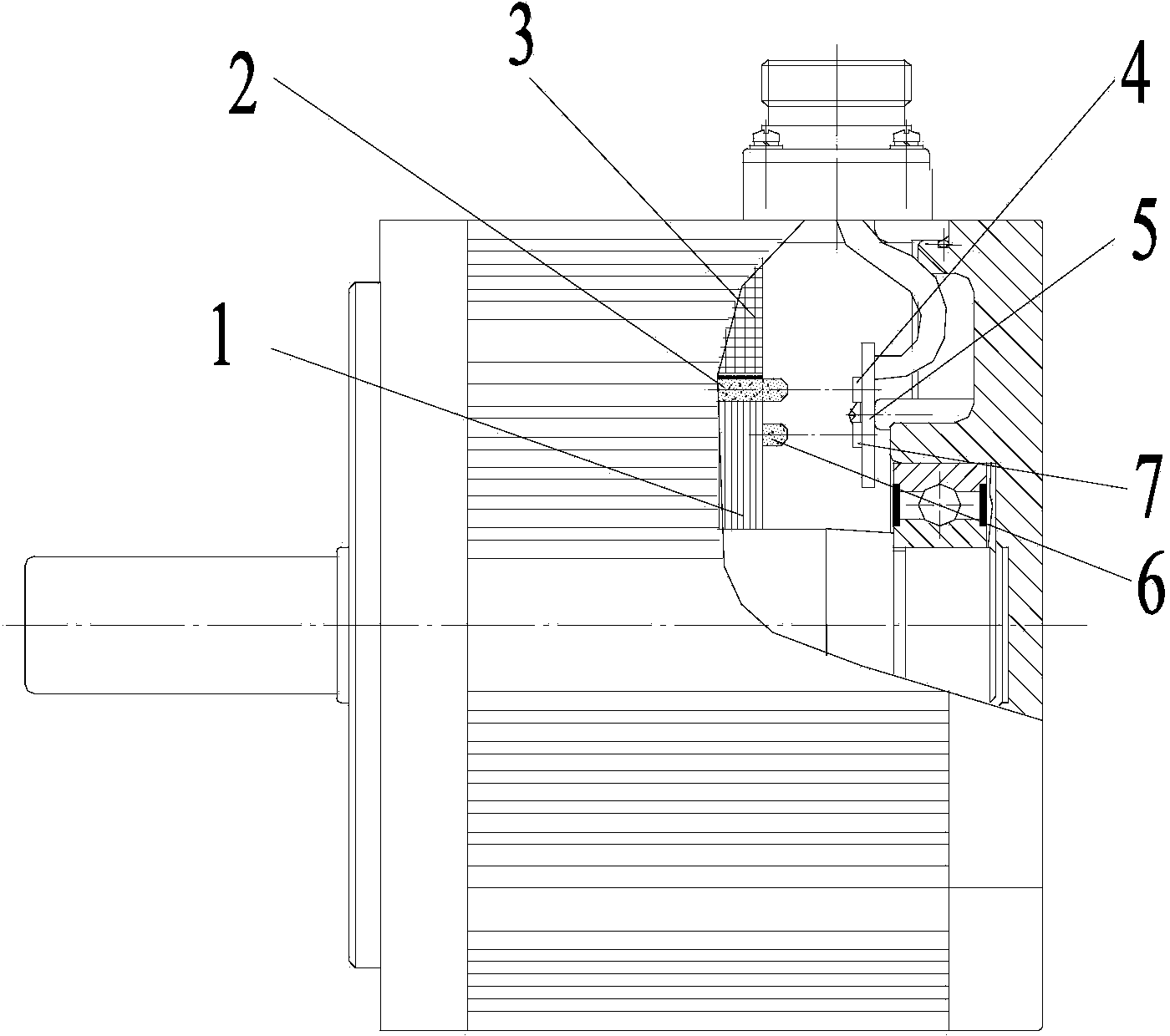

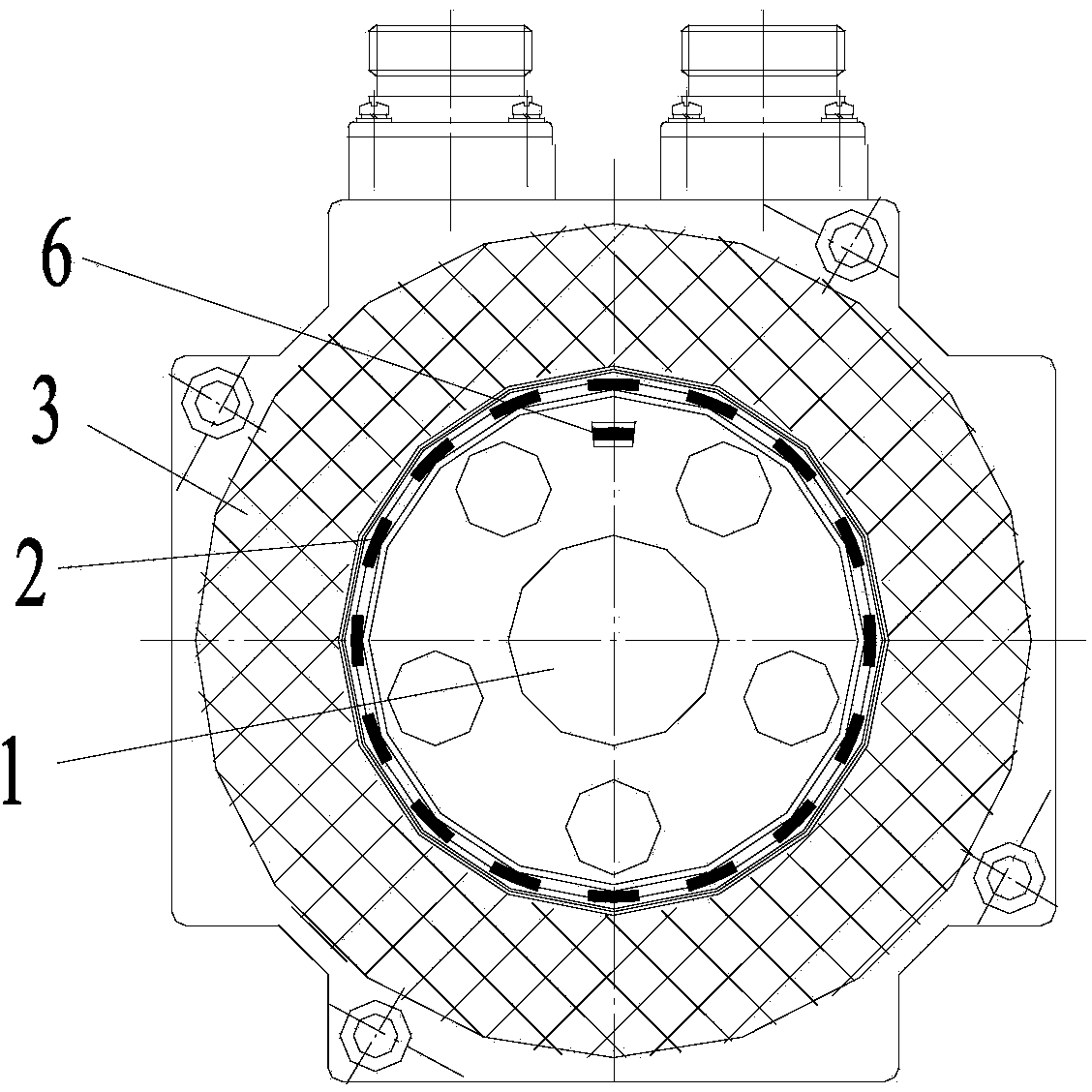

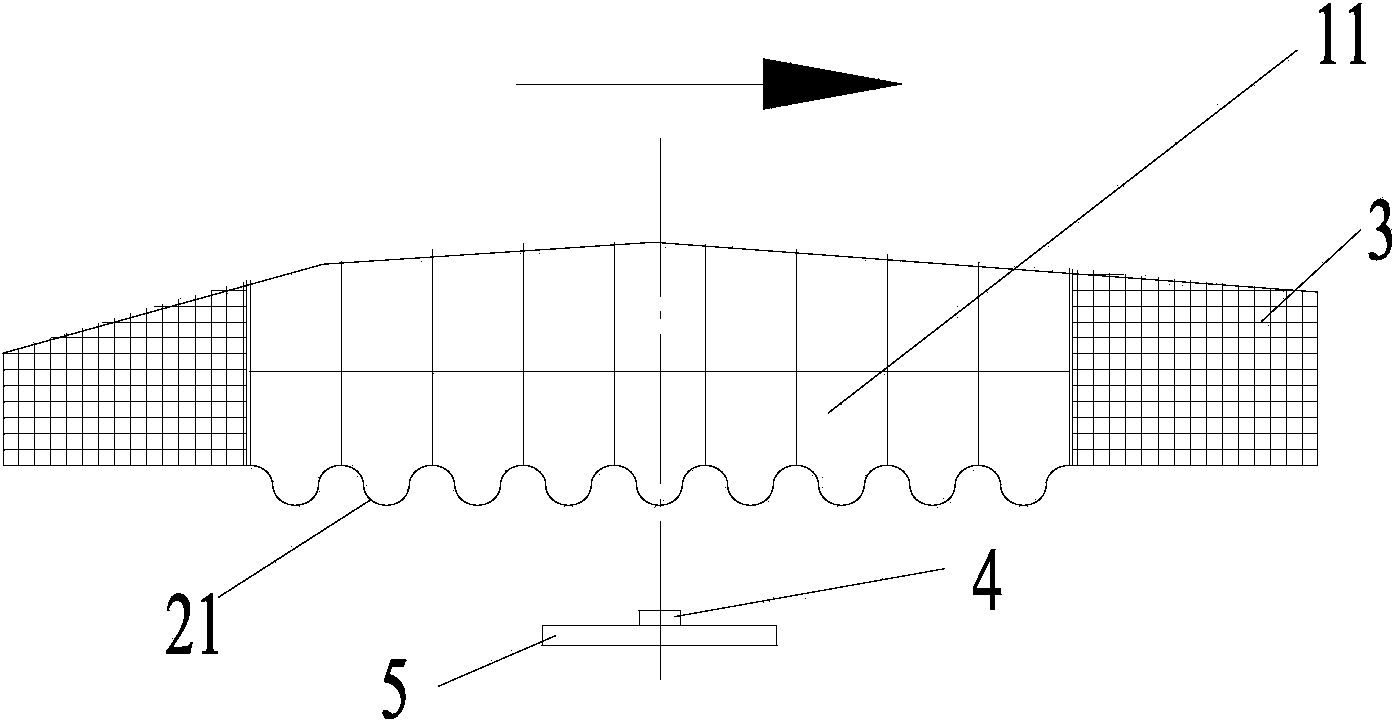

[0035] Such as figure 1 , 2 , 3, the servo motor with the encoder function described in this embodiment includes the rotor 1 and the stator 3 of the traditional motor. The present invention proposes to set the tooth structure 2 on the rotor magnetic tile 11. The tooth structure 2 of the present embodiment shape structure such as image 3 Shown in 21, it is arc-shaped. Here the toothed structure acts as the magnetic grid of the encoder.

[0036] The servo motor also includes a first Hall element 4 (Hall element A in this example), a second Hall element 8 (Hall element B in this example), a zero Hall element 7, a PCB circuit board 5 and a zero magnet 6 , wherein the first Hall element 4, the zero Hall element 7, the PCB circuit board 5, the zero magnet 6, and the positional relationship between the rotor magnetic tile 11 are as follows figure 1 , 2 , 3, the position of the zero point magnet 6 in the motor is as follows figure 2 shown.

[0037] Such as Image 6 As shown,...

example 1

[0053] Example 1: Assume that the current motor rotor rotates to the 14th magnetic grid period, and Figure 14 At point A, since point A is within the interval of 0 to T / 8, it is an increasing interval, so after AD samples sinθ and cosθ values, calculate |tanθ| value, |tanθ|=210, look up the table to get the subdivision 0X0F, the 14th magnetic grid cycle is converted to 0X0E of 16 progress, the magnetic grid cycle number is high, and the subdivision value is low, combined: 0X0E&0X0F=0X0E0F, so the current absolute position value of point A is 0X0E0F.

example 2

[0054] Example 2: Assume that the current motor rotor rotates to the 60th magnetic grid period, and Figure 14 At point B, because point B is within the interval of 5T / 8~3T / 4, it is a decreasing interval, so after AD samples the values of sinθ and cosθ, calculate |cotθ| value, |cotθ|=105, look up the table The score is 0XB6, the 60th magnetic grid cycle is converted to 0X3C with 16 progress, the magnetic grid cycle number is high, and the subdivision value is low, merge: 0X3C&0XB6=0X3CB6, so the current absolute position value of point B is 0X3CB6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com