A modular multi-level photovoltaic grid-connected system and its control method

A modular multi-level, control method technology, applied in photovoltaic power generation, control/regulation systems, and electrical variable adjustment, etc., can solve problems such as output efficiency drop, array power mismatch, low photovoltaic module power, etc., to reduce capacitance The effect of stress, increasing capacity and reducing the harmonic content of inverter output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with accompanying drawing and embodiment the present invention will be further described;

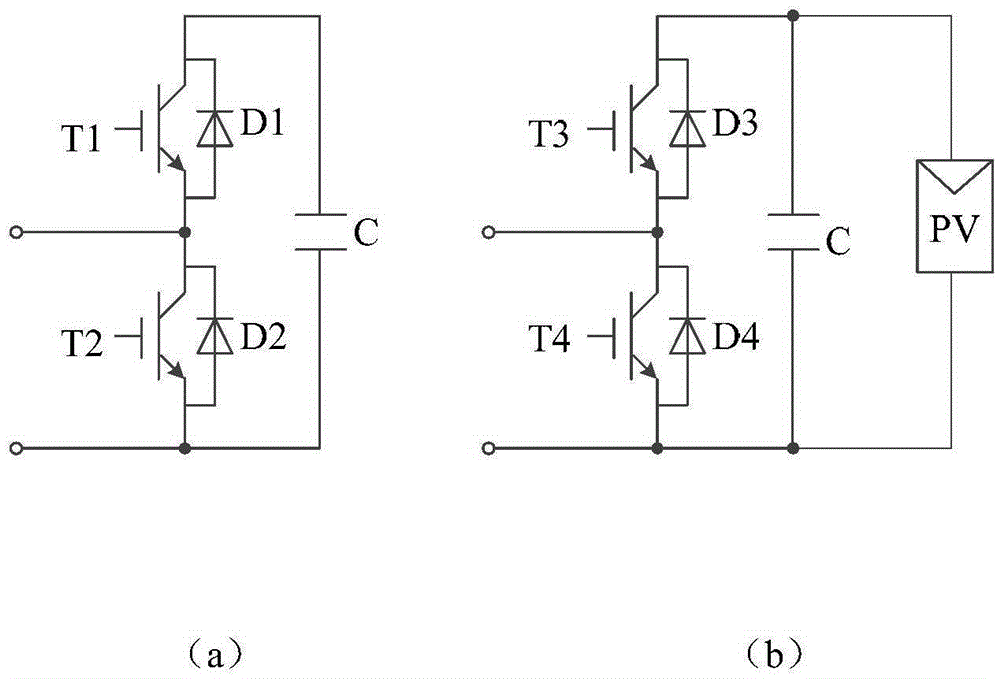

[0045] Such as figure 1 (a) is the SM submodule. The SM consists of two IGBT tubes T1~T2, two diodes D1~D2 and a capacitor C; among them, the emitter of the IGBT tube T1 is connected to the collector of the IGBT tube T2 and constitutes the positive end of the SM, and the collector of the IGBT tube T1 The positive electrode of the electrode capacitor C is connected, and the emitter of the IGBT tube T2 is connected to the negative electrode of the capacitor to form the negative terminal of the SM; D1 is connected in antiparallel with T1, and D2 is connected in antiparallel with T2. The gates of the IGBT tubes T1-T2 all receive switching signals provided by external devices. When the photovoltaic module is in the shade, the half-bridge module generates a compensation voltage to maintain a stable DC voltage.

[0046] Such as figure 1 (b) is the PM submodule. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com