A kind of sealing formation method of lithium ion battery

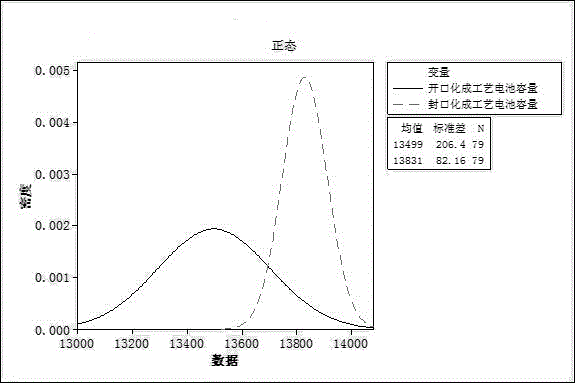

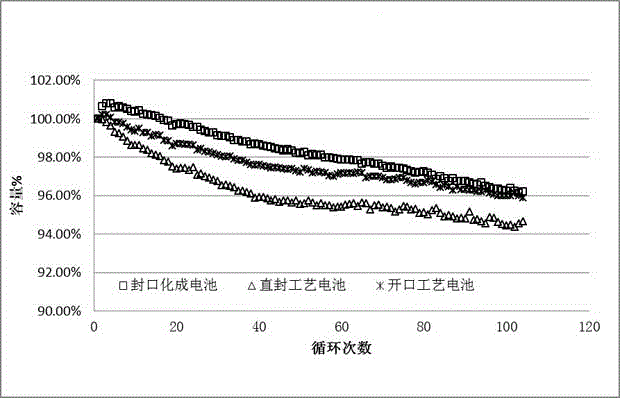

A technology of lithium-ion batteries and formation methods, which is applied in the manufacture of battery pack parts, non-aqueous electrolyte batteries, electrolyte batteries, etc. It can solve the problems of exhaust gas cannot be discharged, long process time, battery moisture absorption, etc., and achieve cycle performance improvement and process Shorter time, more consistent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment one: a kind of sealing formation method of lithium ion battery, it comprises the following steps:

[0028] (a) First reserve the vent hole 4 and the liquid injection port 3 on the battery case, then fill the battery with electrolyte according to the designed amount, and complete the weighing;

[0029] (b) sealing the battery liquid injection port 3 by laser welding;

[0030] (c) Clean the upper cover plate 1 of the battery, and let it stand at room temperature for 2.0 hours to 24.0 hours;

[0031] (d) After standing still, the battery is precharged;

[0032] (e) After the pre-charging is completed, let it stand at room temperature for 0.5 hours to 20.0 hours, open the vent hole on the battery case, and perform vacuum exhaust;

[0033] (f) After exhausting the exhaust gas inside the battery, seal the vent hole on the battery case with steel balls and reinforce it with glue;

[0034] (g) Leave the battery at room temperature and recharge the battery.

[003...

Embodiment 2

[0038] Embodiment two: a kind of sealing formation method of lithium ion battery, it comprises the following steps:

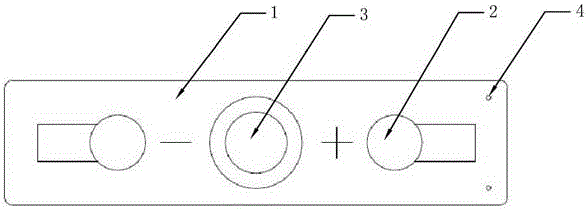

[0039] (a) First, install the upper cover plate 1 of the battery case (refer to the attached image 3 As shown), the vent hole 4 and the liquid injection port 3 are reserved, and then the battery is filled with electrolyte according to the designed amount, and the weighing is completed;

[0040] (b) Seal the battery liquid injection port 3 by welding a safety valve at the liquid injection port 3;

[0041] (c) if image 3 As shown, clean the battery pole 2 and the safety valve, put it in a vacuum box with a vacuum degree of -50 to 65KPa for 2-6 hours, and check the sealing of all welding positions;

[0042] (d) Stand for about 9.0-15.0 hours at a temperature of 30-50°C;

[0043] (e) After standing still, the battery is precharged;

[0044] (f) After the pre-charging is completed, let it stand at room temperature for 0.5-20.0 hours, open the vent hole on the ...

Embodiment 3

[0049] Embodiment three: a kind of sealing formation method of lithium ion battery, it comprises the following steps:

[0050] (a) First reserve the vent hole 4 and the liquid injection port 3 on the battery case, then fill the battery with electrolyte according to the designed amount, and complete the weighing;

[0051] (b) sealing the battery liquid injection port 3 by laser welding;

[0052] (c) Clean the upper cover plate 1 of the battery, and let it stand at room temperature for 2.0 hours to 24.0 hours;

[0053] (d) After standing still, the battery is precharged;

[0054] (e) After the pre-charging is completed, let it stand at room temperature for 8.0 hours to 36.0 hours;

[0055] (f) Leave the battery at room temperature and recharge the battery;

[0056] (g) After completing the recharging, open the exhaust hole on the battery case to vacuumize and exhaust;

[0057] (h) After exhausting the exhaust gas inside the battery, seal the vent hole on the battery case wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com