A continuous vacuum ultraviolet light ozone surface cleaning and oxidation modification equipment and its application method

A vacuum ultraviolet light and surface cleaning technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of long process time, low degree of equipment automation, shortened process processing time, etc., to achieve safe and reliable equipment, The effect of sample cleaning and oxidation modification is good, and the effect of shortening the processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further illustrated and described in detail below in conjunction with the accompanying drawings and specific examples:

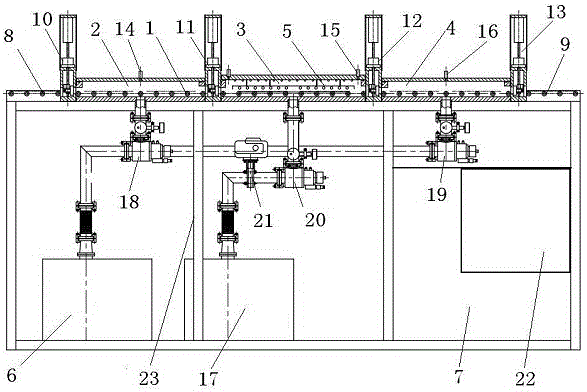

[0062] The structure of continuous vacuum ultraviolet light / ozone surface cleaning and oxidation modification equipment designed in the present invention is as follows: figure 1 shown. As can be seen from the figure, the equipment is mainly composed of a loading and unloading conveying system 1, a preheating chamber 2, a process chamber 3, a cooling chamber 4, an ultraviolet light source system 5, a vacuum system 6, and an automatic control and monitoring system 7.

[0063] The loading and unloading conveying system 1 includes five sets of conveying mechanisms, one set is located at the feed port 8, one set is located at the discharge port 9, and one set is located in the preheating chamber 2, the process chamber 3, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com