Roller coating conversion treatment agent for colored coated steel plate

A color-coated steel sheet and conversion treatment technology, which is applied in the direction of metal material coating technology, can solve the problems of poor corrosion resistance and high production cost, and achieve the advantages of convenient use, production cost control, excellent corrosion resistance and adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Preparation of conversion treatment agent:

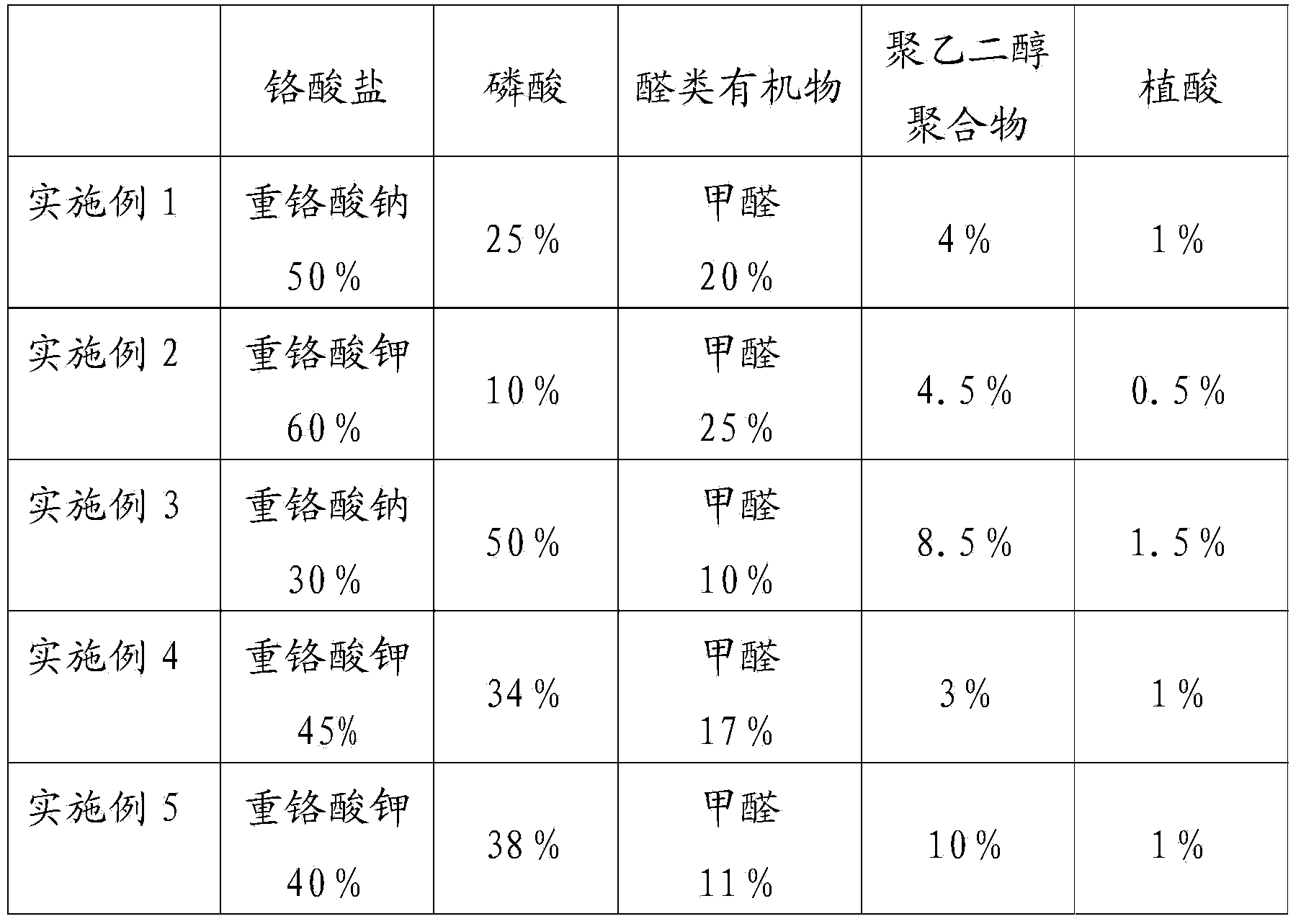

[0027] First, aldehyde organic matter is dissolved in part of deionized water to make an aldehyde type organic matter solution for subsequent use; then the chromate and phosphoric acid are dissolved in part of deionized water to make a solution containing chromate and phosphoric acid, and then the solution containing chromic acid Heat the solution of salt and phosphoric acid to 75-85°C, slowly add the aldehyde organic matter solution while stirring; then heat to 90±2°C and keep it for 120-130min, then stop heating, naturally cool to 50±2°C, add while stirring Phytic acid and polyethylene glycol polymer with a molecular weight of 10,000-60,000, then add the rest of deionized water according to the ratio of solute to deionized water weight ratio of 1:9-12, stir for 15-20 minutes, and cool to room temperature to obtain Conversion treatment agent 1-5. 1-5 conversion treatment agent does not contain Cr 6+ . Components and propor...

Embodiment 1

[0030] Example 1: When the machine speed is 90m / min and the roller coating pressure is 200kg, the conversion treatment agent 1 is evenly coated on the surface of the steel strip, and then dried. The drying temperature is 85°C, and the drying time is 15 seconds, the thickness of the converted layer is 1.5 μm, and the surface of the converted layer has no rust. Neutral salt spray test for 168 hours, no rust on the surface of the conversion layer. After the coating is applied, the coating adhesion is excellent: the T-bend value is 1T, the cupping value is 8.0mm, and the reverse impact energy is 10J.

Embodiment 2

[0031] Example 2: When the machine speed is 120m / min and the roller coating pressure is 250kg, the conversion treatment agent 2 is evenly coated on the surface of the steel strip, and then dried. The drying temperature is 90°C, and the drying time is 9 seconds, the thickness of the conversion layer is 1.8 μm, and the neutral salt spray test lasts 192 hours, and the conversion layer surface has no rust. After the coating is applied, the coating adhesion is excellent: the T-bend value is 2T, the cupping value is 7.5mm, and the reverse impact energy is 9J.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com