Split type methane oxidation-denitrification reactor and method thereof

A methane oxidation and reactor technology, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc. Low problems, to achieve the effect of maximizing utilization, reducing and removing nitrate, and avoiding the risk of explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

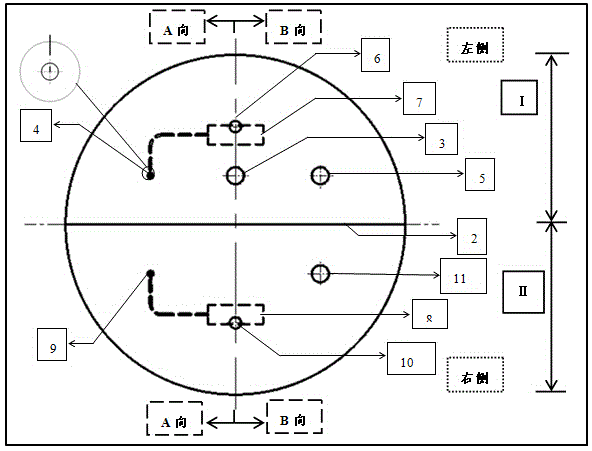

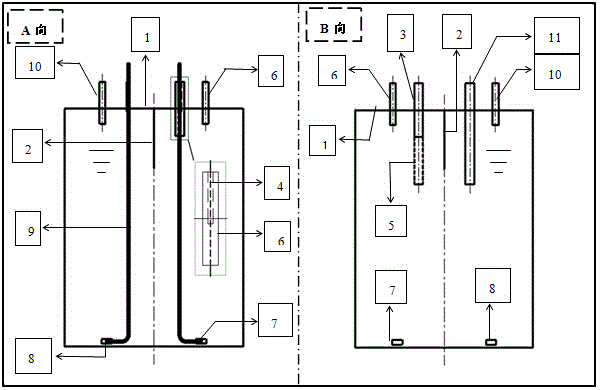

[0021] Such as figure 1 with 2 As shown, the divided methane oxidation-denitrification reactor includes a reactor body, the top of the reactor body is provided with a cover plate 1, and the center of the cover plate 1 is provided with a partition 2, which divides the reactor into two parts; the left side of the reactor is In the methane area I, the water inlet pipe 3 is provided in the center of the left side of the cover plate 1 close to the 1 / 3 of the partition plate 2, the methane inlet pipe 4 and the methane area outlet pipe 5 are arranged on the left side of the cover plate 1, and the left side of the cover plate 1 is close to the edge A methane overflow pipe 6 is set in the center of 1 / 3, a methane aeration head 7 is set in the center of the left bottom of the reactor, and is connected to the methane inlet pipe 4, and the right side of the reactor is the oxygen area II, which is equipped with an oxygen aeration head 8, oxygen The intake pipe 9, the oxygen overflow pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com