Wire electrical discharge machine with anti-rust function

An electrical discharge machine and machining fluid technology, applied in electric machining equipment, metal machining equipment, circuits, etc., can solve problems such as insufficient current to achieve anticorrosion, shortened life of anticorrosion electrodes, and deterioration of workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

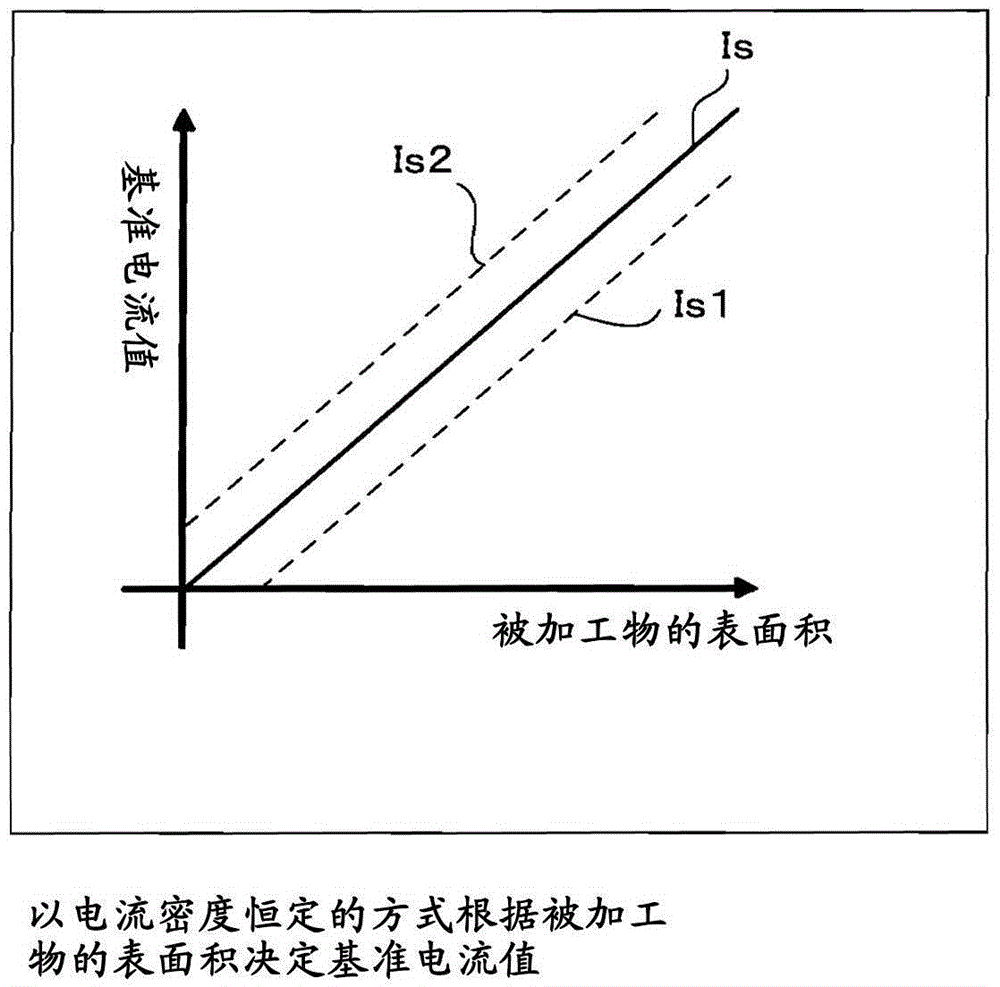

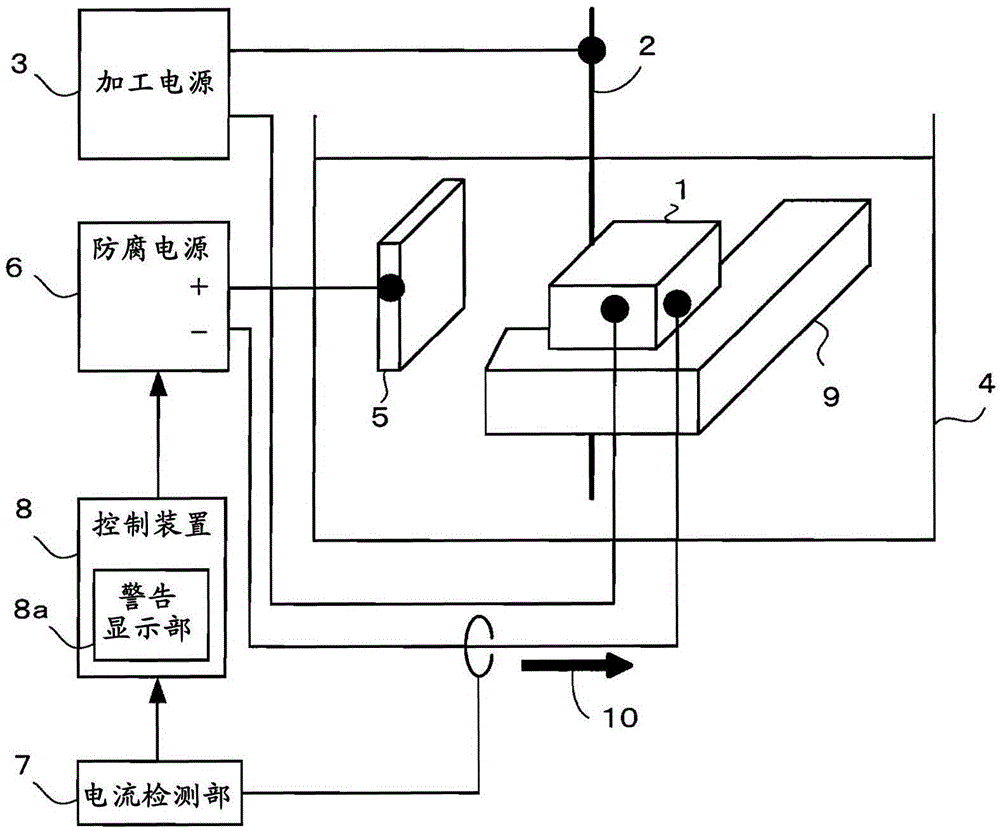

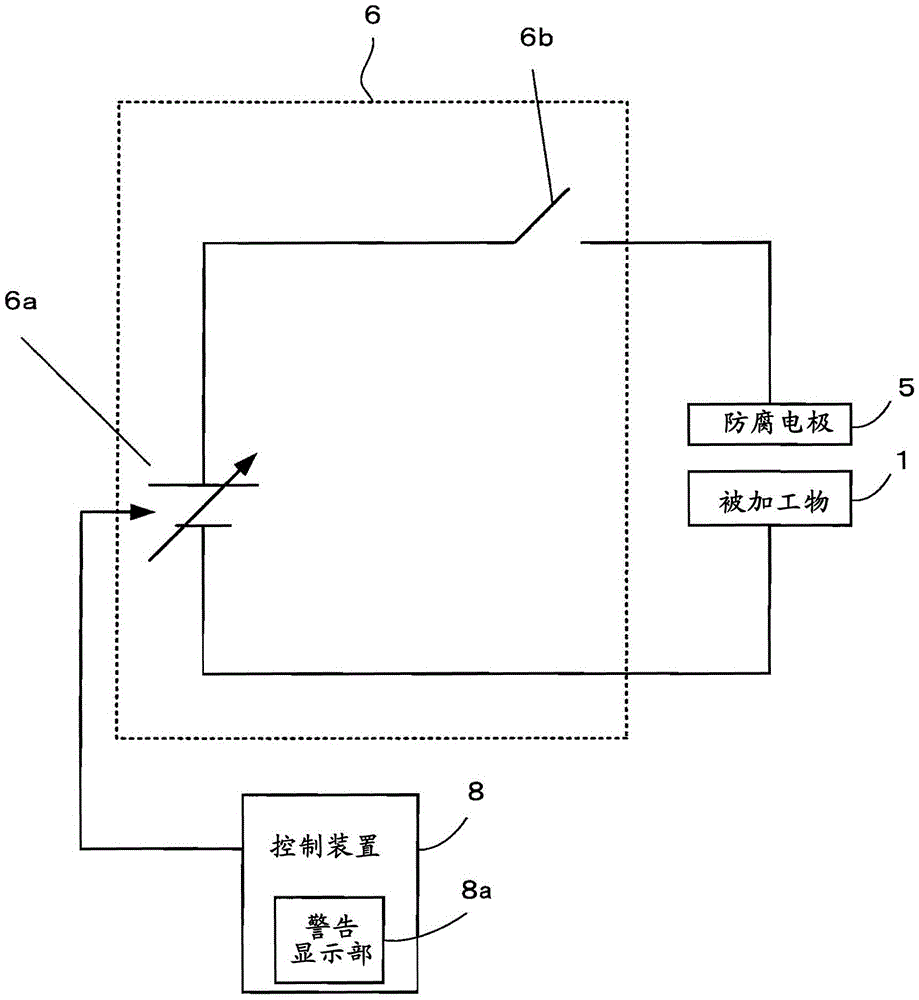

[0017] First, in the following embodiments, the current density is a value obtained by dividing the current value of the current supplied from the anticorrosion power supply by a physical quantity related to the surface area of the workpiece. When a voltage is applied to the workpiece and the anticorrosion electrode to prevent corrosion of the workpiece, when the current density of the workpiece is smaller than a predetermined value, there is a problem that the corrosion protection cannot be fully achieved. In addition, when the current density is too large, there is Shortened life of anti-corrosion electrodes or deterioration of workpiece due to hydrogen generation. Therefore, in electrical discharge machining, if the current density is not controlled in such a way that the current density for rust prevention supplied from the anti-corrosion power supply becomes constant by a predetermined value, the size of the workpiece, that is, the surface area, cannot sufficiently Anti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com