A kind of preparation method of 3d porous cobalt tin molybdenum trimetallic catalyst

A technology of three metals and catalysts, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of cumbersome synthesis steps, achieve simple synthesis steps, improve catalytic efficiency, and increase electrical conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

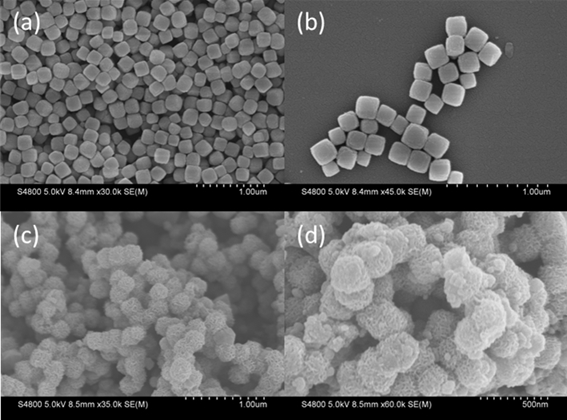

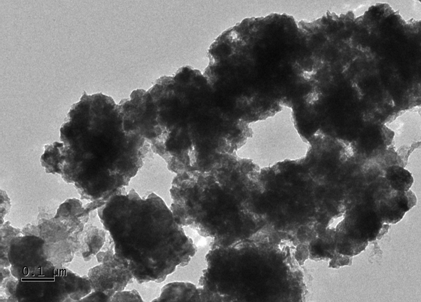

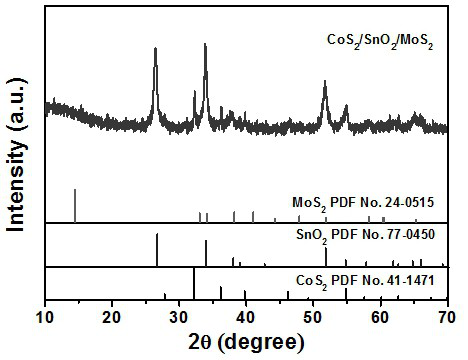

Embodiment 1

[0030] Dissolve 1 mmol cobalt chloride hexahydrate and 0.5 mmol sodium citrate dihydrate in 35 mL deionized water and stir for several minutes. A 5 mL ethanol solution containing 1 mmol of tin chloride pentahydrate was added thereto and stirred until the solution was fully mixed. Subsequently, 30 mL of 2 M sodium hydroxide solution was added dropwise. The reaction was stirred at room temperature for 0.5 h. Finally, the final pink precipitate was collected by centrifugation, washed several times with deionized water and absolute ethanol, respectively, and then vacuum-dried at 50 °C for 12 h to obtain cubic CoSn(OH) 6 Precursor. Add 50 mg of the above cubic CoSn(OH) 6 The precursor and 25 mg of ammonium tetrathiomolybdate were dispersed in 30 mL of deionized water. After the solution was fully dispersed, it was packaged in a polytetrafluoroethylene reactor, and centrifuged and washed after hydrothermal reaction at 160 °C for 8 h. , Vacuum drying. The obtained dried product ...

Embodiment 2

[0032] Dissolve 1 mmol cobalt chloride hexahydrate and 0.75 mmol sodium citrate dihydrate in 35 mL deionized water and stir for several minutes. Then add 5 mL of ethanol solution containing 1 mmol of tin chloride pentahydrate and stir until the solution is fully mixed. Subsequently, 25 mL of 2 M sodium hydroxide solution was added dropwise. The reaction was stirred at room temperature for 0.5 h. Finally, the final pink precipitate was collected by centrifugation, washed several times with deionized water and absolute ethanol, respectively, and then vacuum-dried at 50 °C for 12 h to obtain cubic CoSn(OH) 6 Precursor. Add 50 mg of the above cubic CoSn(OH) 6 The precursor and 25 mg of ammonium tetrathiomolybdate were dispersed in 30 mL of deionized water. After the solution was fully dispersed, it was packaged in a polytetrafluoroethylene reactor, and centrifuged and washed after hydrothermal reaction at 160 °C for 10 h. , Vacuum drying. The obtained dried product was kept a...

Embodiment 3

[0034] Dissolve 1 mmol cobalt chloride hexahydrate and 1 mmol sodium citrate dihydrate in 35 mL deionized water and stir for several minutes. Then add 5 mL of ethanol solution containing 1 mmol of tin chloride pentahydrate and stir until the solution is fully mixed. Subsequently, 20 mL of 2 M sodium hydroxide solution was added dropwise. The reaction was stirred at room temperature for 0.5 h. Finally, the final pink precipitate was collected by centrifugation, washed several times with deionized water and absolute ethanol, respectively, and then vacuum-dried at 50 °C for 12 h to obtain cubic CoSn(OH) 6 Precursor. Add 50 mg of the above cubic CoSn(OH) 6The precursor and 50 mg of ammonium tetrathiomolybdate were dispersed in 30 mL of deionized water. After the solution was fully dispersed, it was packaged in a polytetrafluoroethylene reactor, and centrifuged and washed after hydrothermal reaction at 160 °C for 6 h. , Vacuum drying. The obtained dried product was kept at 450...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com