Piston ring for an internal combustion engine

A technology for piston rings and internal combustion engines, applied in the field of piston rings, can solve the problems of increasing manufacturing costs and material costs, and achieve the effects of prolonging wear life and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

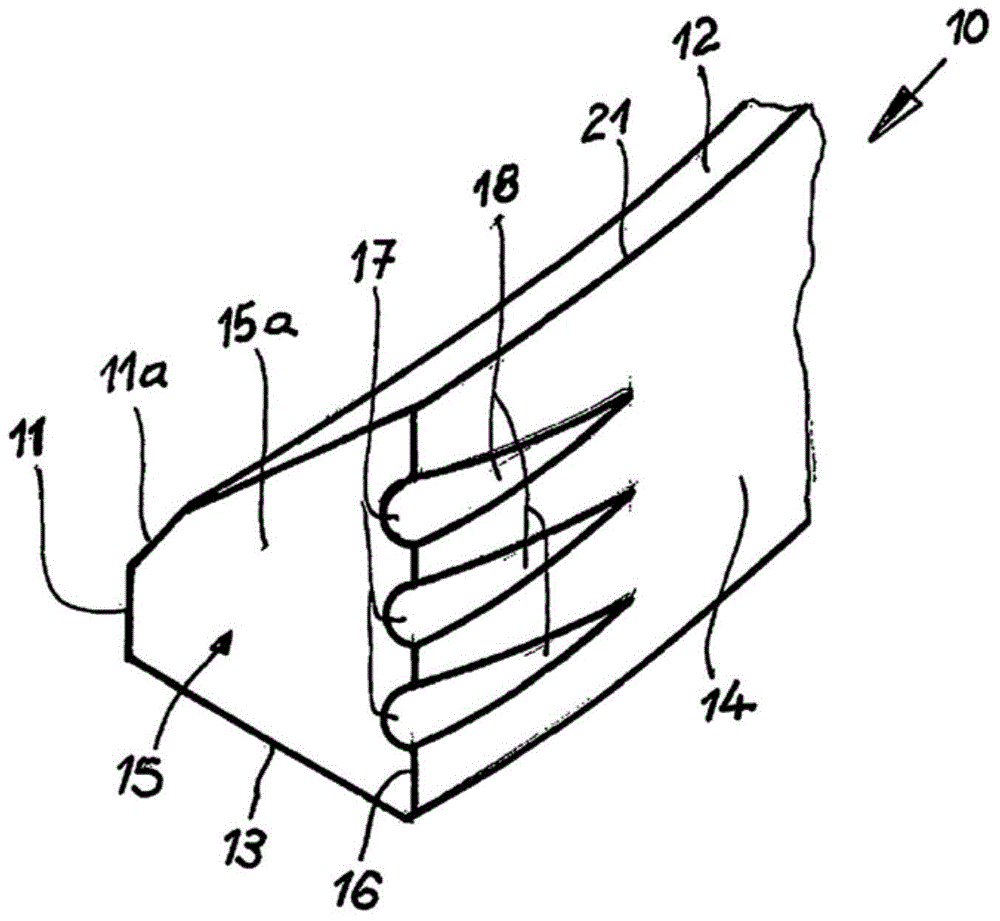

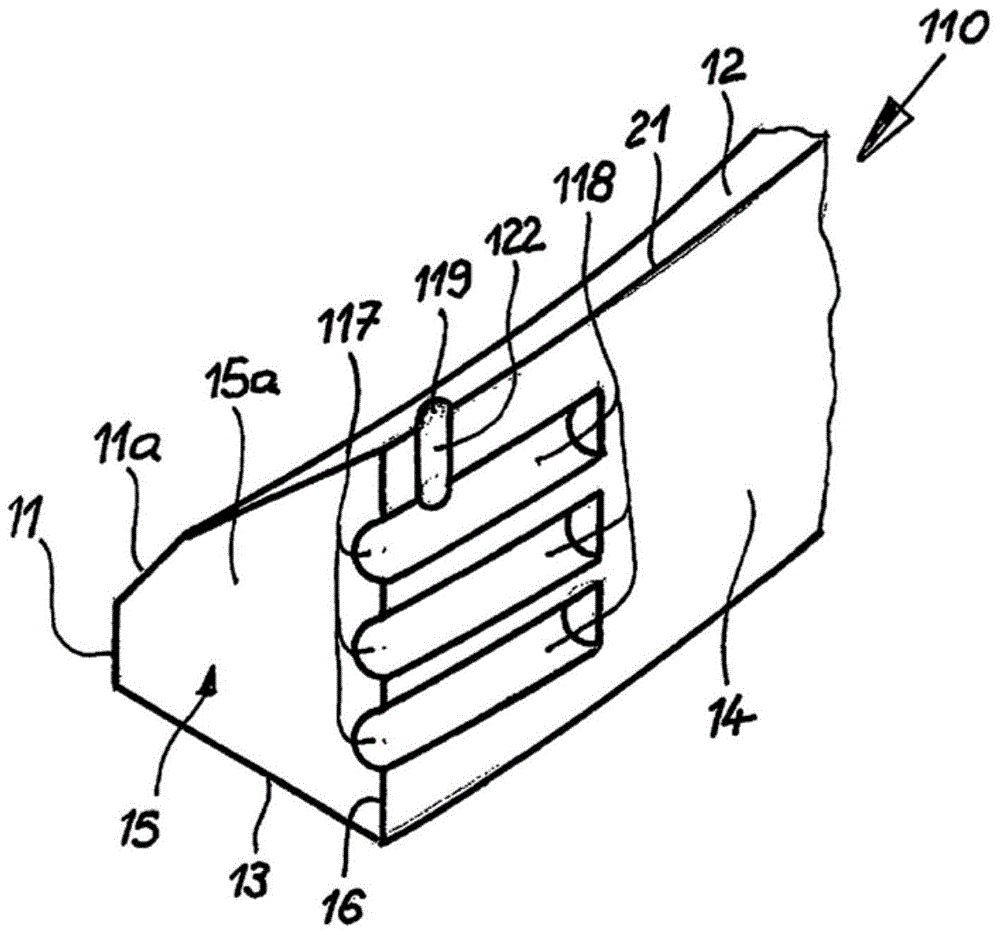

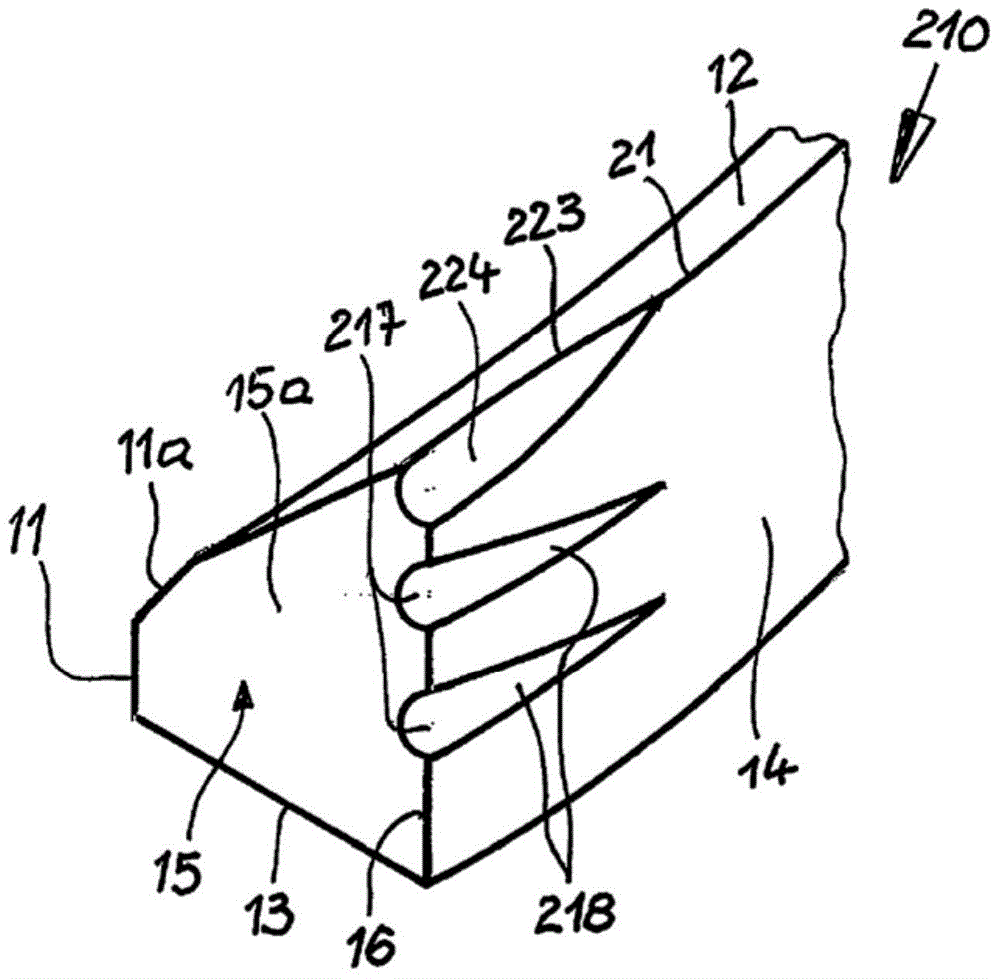

[0027] figure 1 A first embodiment of a piston ring 10 of the invention is shown. The piston ring 10 has, in a known manner, a ring back 11 provided with a bevel 11 a , an upper ring side 12 , a lower ring side 13 and a ring contact surface 14 . The ring contact surface 14 adjoins the upper ring side 12 via an edge 21 . The piston ring 10 also has two free ring butt ends which delimit a gap or ring seam in a known manner. figure 1 The ring butt end 15 is shown provided with an end face 15a. The end face 15 a adjoins the ring contact face 14 via an edge 16 . For the sake of clarity, the normally provided coating of the ring contact surface 13 , which is applied with a coating agent, in particular a friction-reducing layer, is not shown.

[0028] The piston ring 10 according to the invention has at least one opening which forms the fluid connection of the ring contact surface 14 to the ring back 11 . In the assembled piston-cylinder unit of an internal combustion engine, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com