Method for detecting initial position of sensorless permanent magnet synchronous motor

A permanent magnet synchronous motor, initial position detection technology, applied in the control of generator, motor generator control, electronic commutation motor control and other directions, can solve the problems of difficult identification signal detection, motor rotation defects, etc., to avoid motor rotation, Easy to achieve and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0017] Combine below Figure 1 to Figure 3 Describe the specific embodiment of the present invention, this embodiment comprises the following steps:

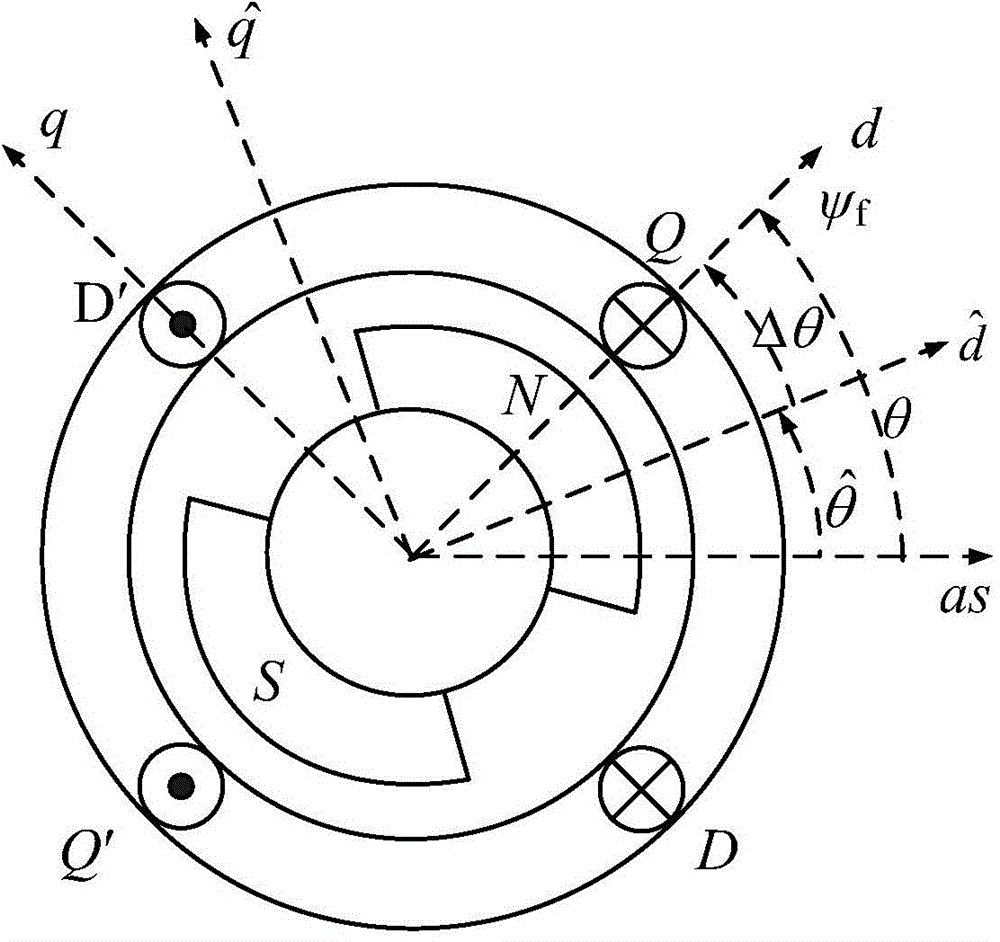

[0018] Step 1: If figure 1 As shown in the physical model diagram of the permanent magnet synchronous motor in the synchronous rotating coordinate system, the actual angle is defined as θ, and the estimated angle is And lagging behind θ, the estimated angle error is Δθ, the actual direct axis is the d axis, the actual quadrature axis is the q axis, and the estimated direct axis is axis, the estimated intersection axis is axis, the actual synchronous rotating coordinate system is d-q, and the estimated synchronous rotating coordinate system is Then, under the condition that the motor is in a static state, open-loop control is performed on the current to initialize the initial position of the rotor, that is, an initial position of the rotor is arbitrarily assumed first.

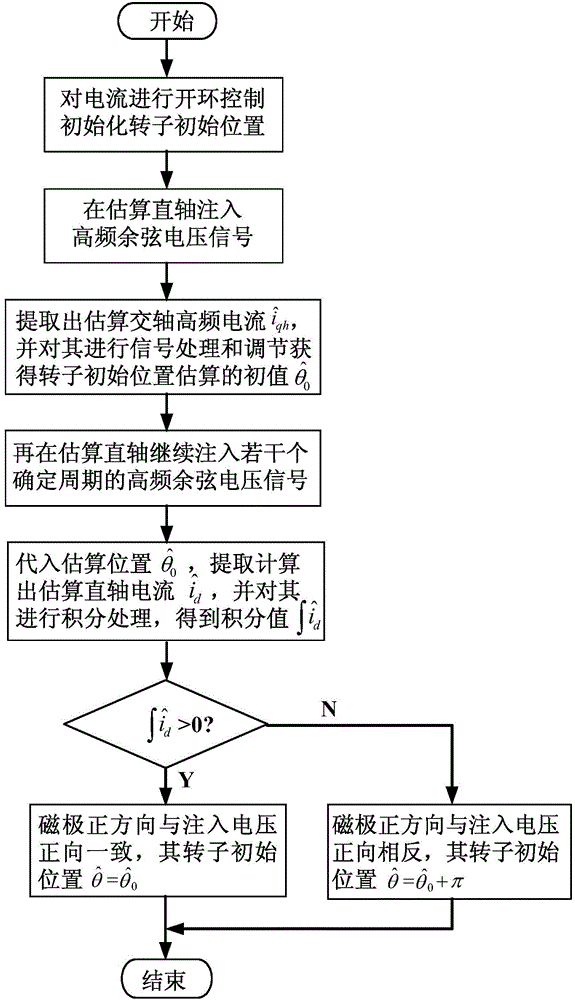

[0019] Step 2: If image 3 Shown in the flow chart...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com