Semi direct drive permanent magnet wind turbine generator bearing lubrication system

A technology for lubricating wind turbines and bearings, which is applied to the lubrication of engines, bearing components, shafts and bearings, etc., and can solve problems such as rising bearing temperature and poor grease discharge channels, so as to increase power generation, reduce heat generation, reduce The effect of economic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

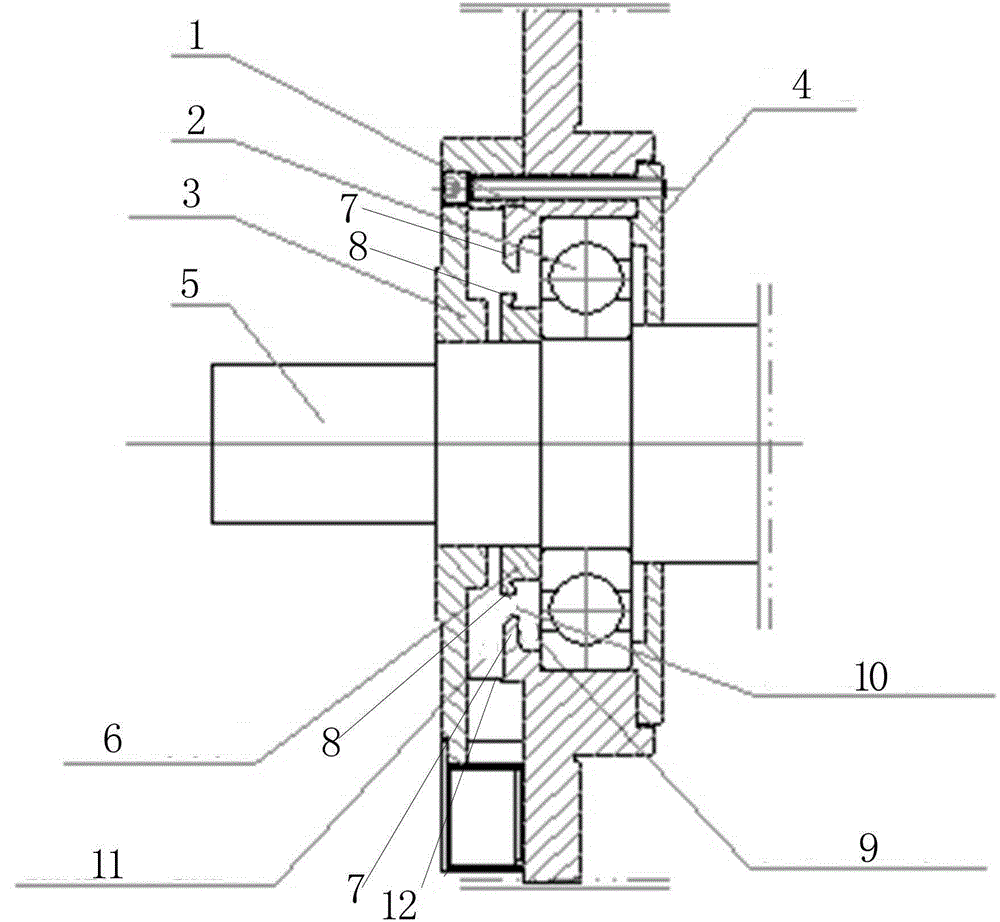

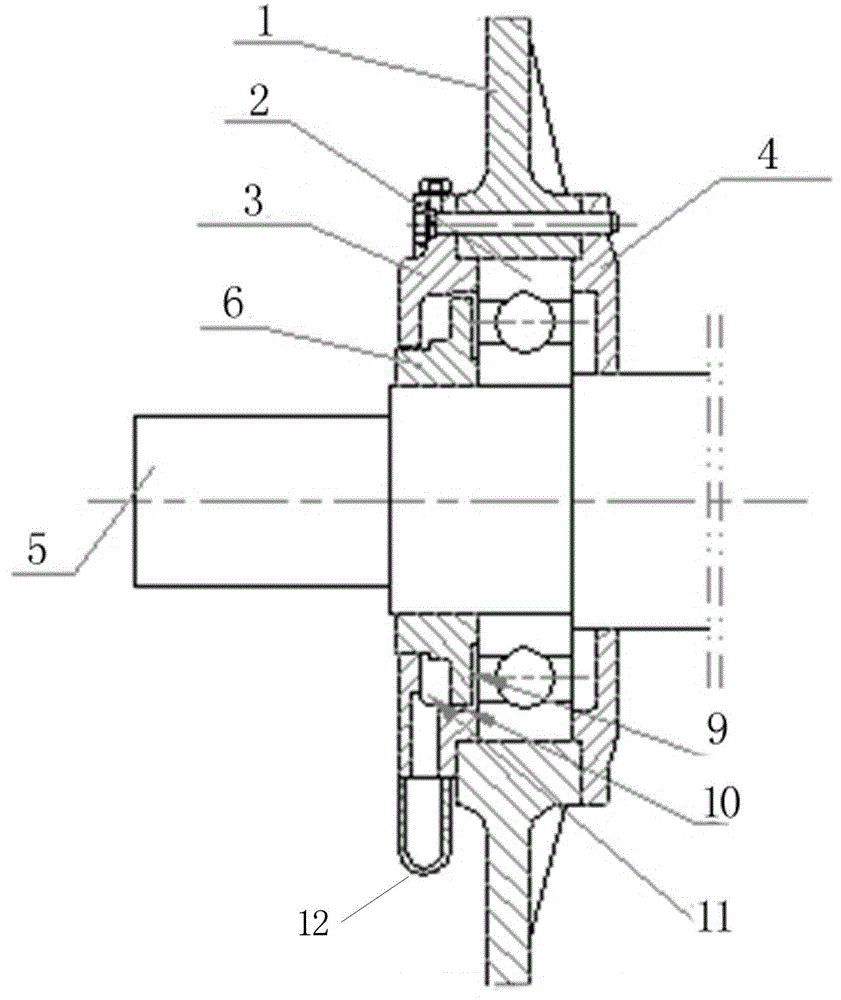

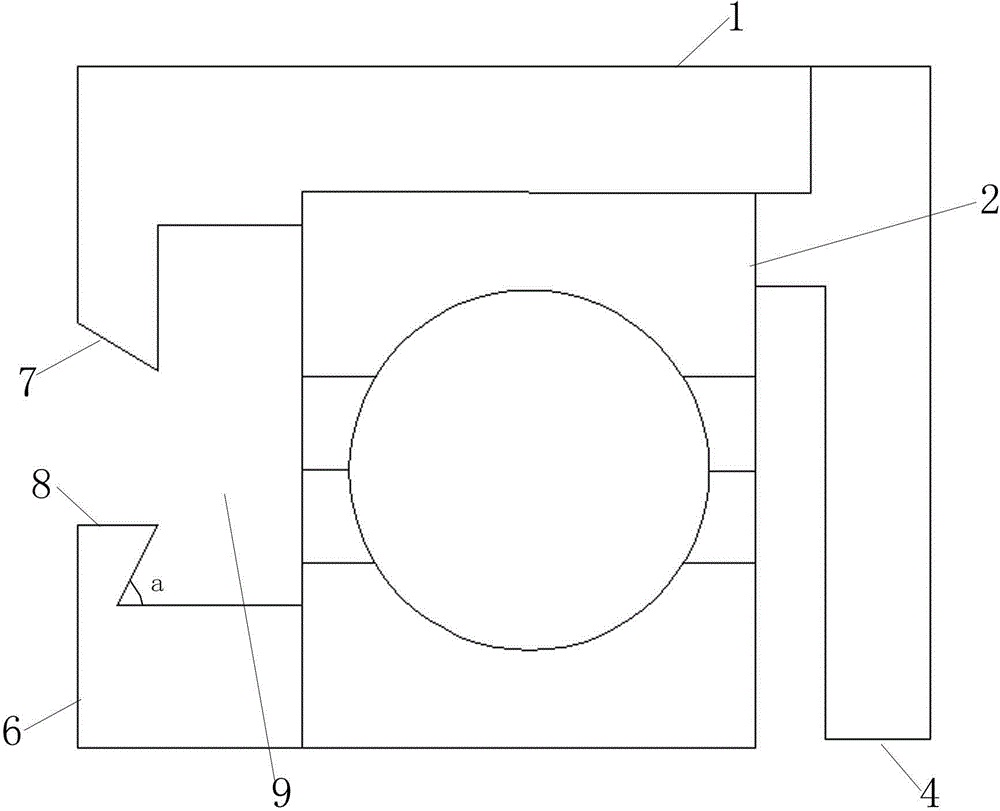

[0030] A bearing lubrication system for a semi-direct drive permanent magnet wind power generator, comprising an end cover 1 with a bearing chamber, a bearing 2 arranged in the bearing chamber of the end cover 1, and bearing outer covers respectively arranged on both sides of the bearing chamber of the end cover 1 3 and the bearing inner cover 4; the rotating shaft 5 passing through the bearing 2 is provided with an oil seal 6 at the part located inside the bearing outer cover 3; the end cover 1 is located between the outer surface of the bearing 2 and the inner side of the bearing outer cover 3 toward the axis of the rotating shaft The oil deflecting ring 7 is protruded from the circle in the direction, and the position corresponding to the oil seal 6 and the oil deflecting ring 7 extends to the side away from the axial direction of the rotating shaft 5 to form an oil throwing ring 8; The waste grease storage space 9 corresponding to the position of the bearing ball is formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com