Liquid removing device used outside water cooling type vertical condenser pipes

A condensing tube and water-cooled technology, which is applied in the field of liquid removal device, can solve the problems such as the decrease of the heat transfer effect of the condensing tube, the reduction of the condensation thermal resistance, and the weakening of the condensation efficiency, so as to improve the continuous working time, enhance the disturbance, and increase the heat transfer and the effect of condensation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

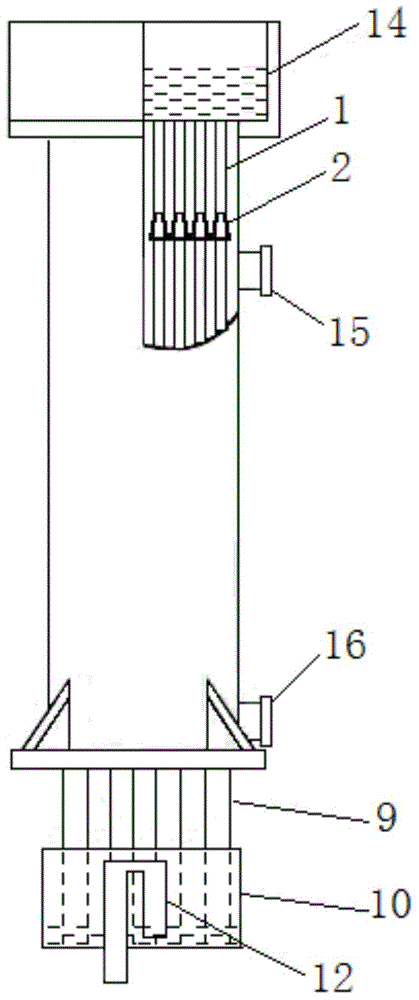

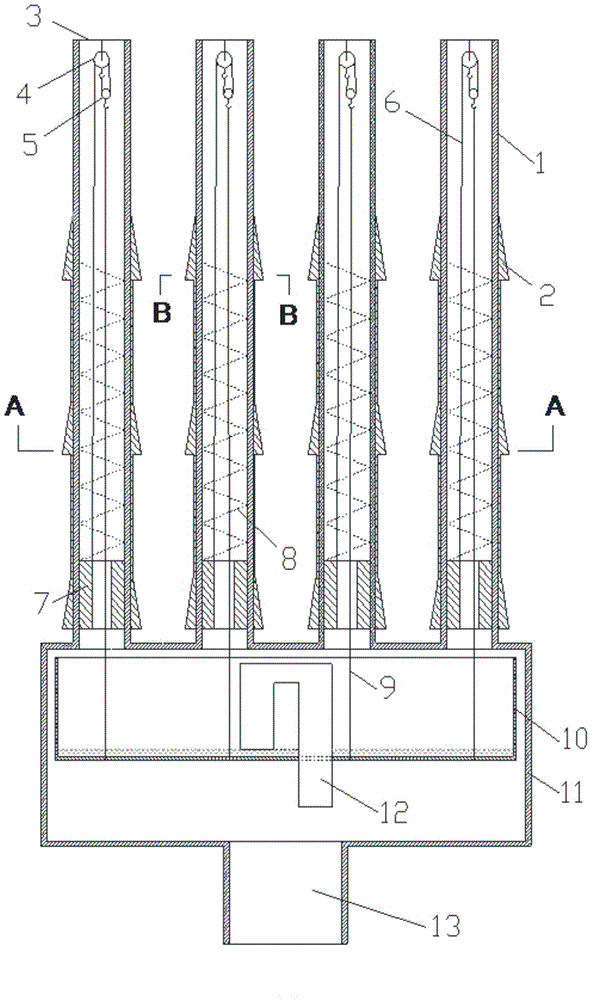

[0035] like Figure 1-Figure 5 As shown, the water-cooled vertical condenser tube external scraping device of the present invention consists of a condenser tube 1, a scraping device 2, a support frame 3, a fixed pulley 4, a movable pulley 5, a pulley line 6, a suspension ring magnet 7, a spring 8. Suspension line 9, suspension basin 10, thick pipeline 11, siphon 12, cooling water outlet 13. Cooling water enters in the condensation pipe 1 by the top water tank 14, and flows out from the bottom of the condensation pipe 1, flows into the suspended water receiving basin, and flows out from the siphon pipe 12 when reaching a certain liquid level in the water receiving basin. Refrigerant vapor enters the condenser from the condensed gas inlet 15 on the top of the wall, and flows out from the condensed liquid outlet 16 after being condensed into liquid on the outer wall of the condensing pipe 1 . The inside of the condensation pipe 1 is cooling water, and the space outside the pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com