Turbine multi-stage air seal structure

A turbine and air seal technology, applied in the direction of preventing leakage, engine components, machines/engines, etc., can solve problems such as restricting the application of radial turbines and compressors, affecting the reliability of thrust bearings, and difficulty in sealing, achieving a compact structure, Ease of assembly and improved sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

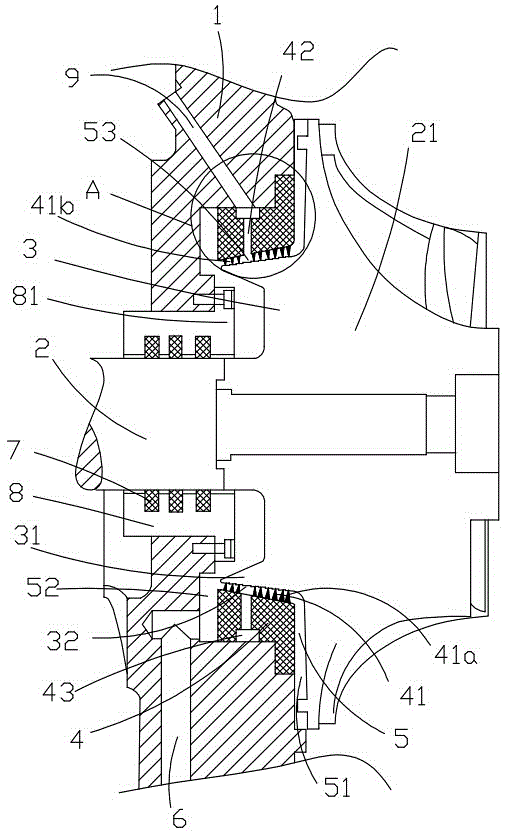

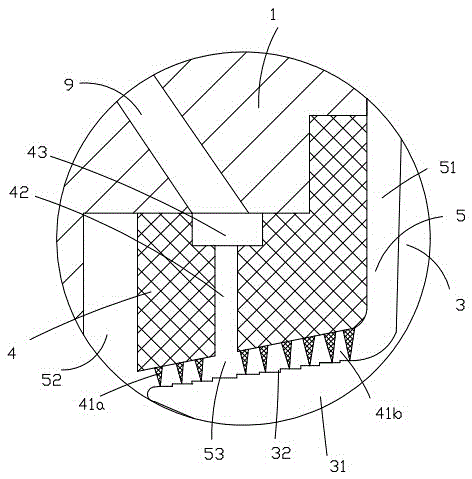

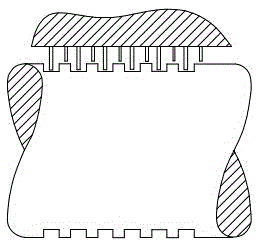

[0027] Figure 1 to Figure 2 Shown is the structural representation of the present invention. Figure 3 to Figure 4 It is a schematic diagram of a comb-teeth labyrinth seal and a multi-stage labyrinth seal in the background technology.

[0028] The reference signs are: housing 1, shaft 2, impeller 21, balance disc 3, disc convex body 31, balance piston 32, stepped seal 4, comb teeth 41, seal teeth 41a, seal cavity 41b, medium pressure Connecting cavity 42, gas collecting ring 43, isolation gap 5, high pressure gap 51, low pressure gap 52, medium pressure gap 53, low pressure air induction pipe 6, sealing floating ring 7, sealing body 8, connecting flange 81, medium pressure air induction pipe 9 .

[0029] The turbine multi-stage air seal structure of the present invention includes a casing 1 and a shaft 2 passing through the casing 1, an imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com