Detachable overhung steel beam pre-buried fixing device with horizontal fixing assembly

A technology for fixing components and fixing devices, which is applied to the accessories of scaffolding, scaffolding supported by building structures, buildings, etc., can solve the problems of affecting the stability of the outer frame system, not being able to play a fixed role, and not being able to repeatedly turn over profits, etc., to achieve Save labor input, fast installation speed, and ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

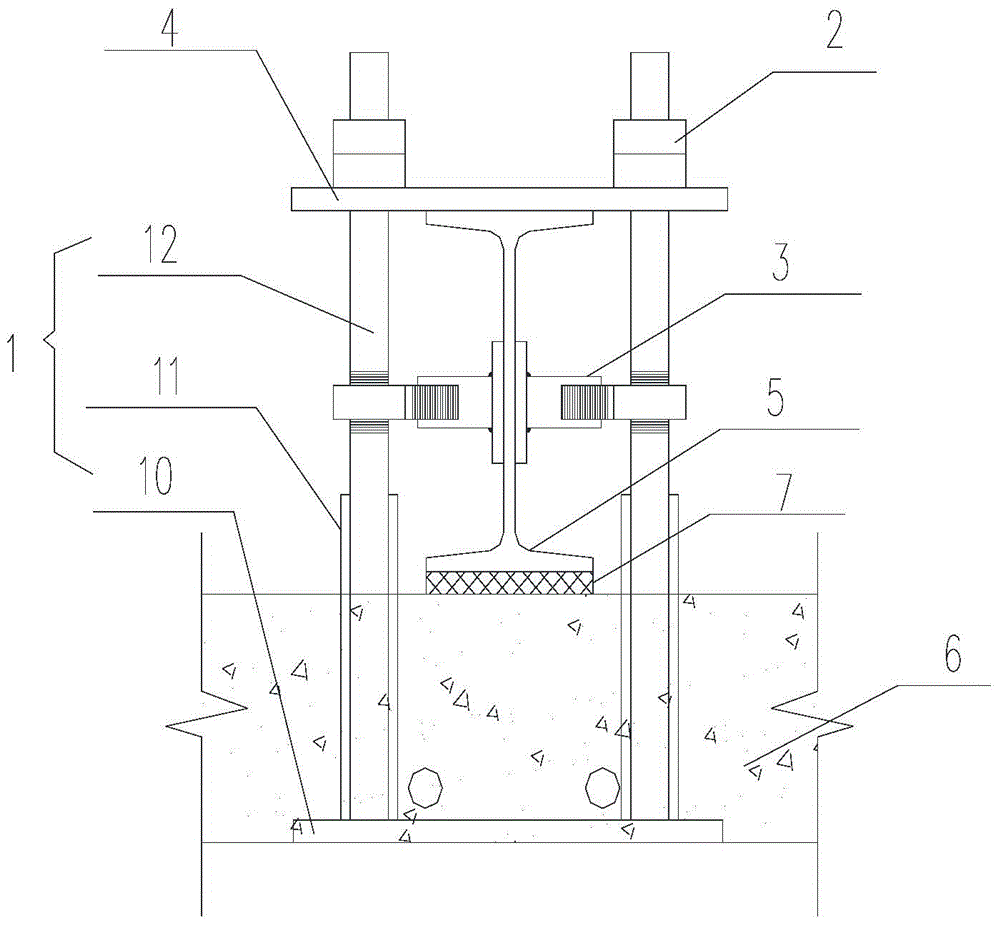

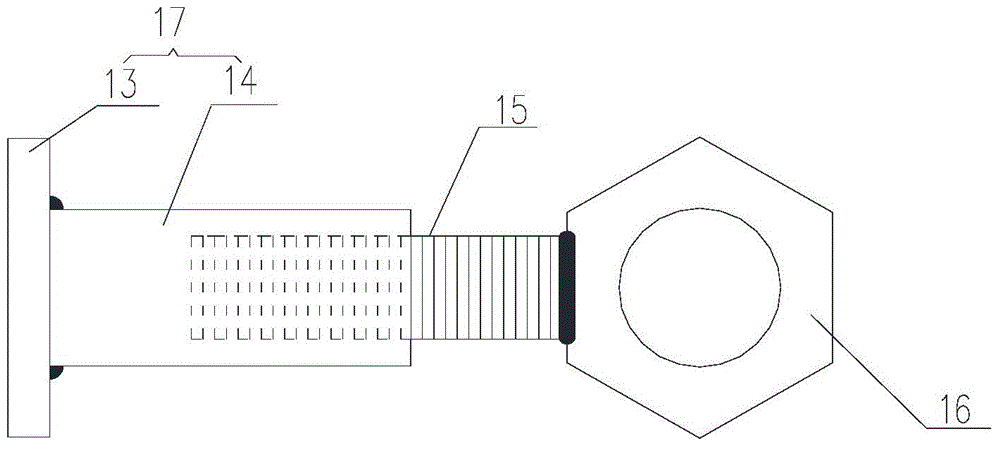

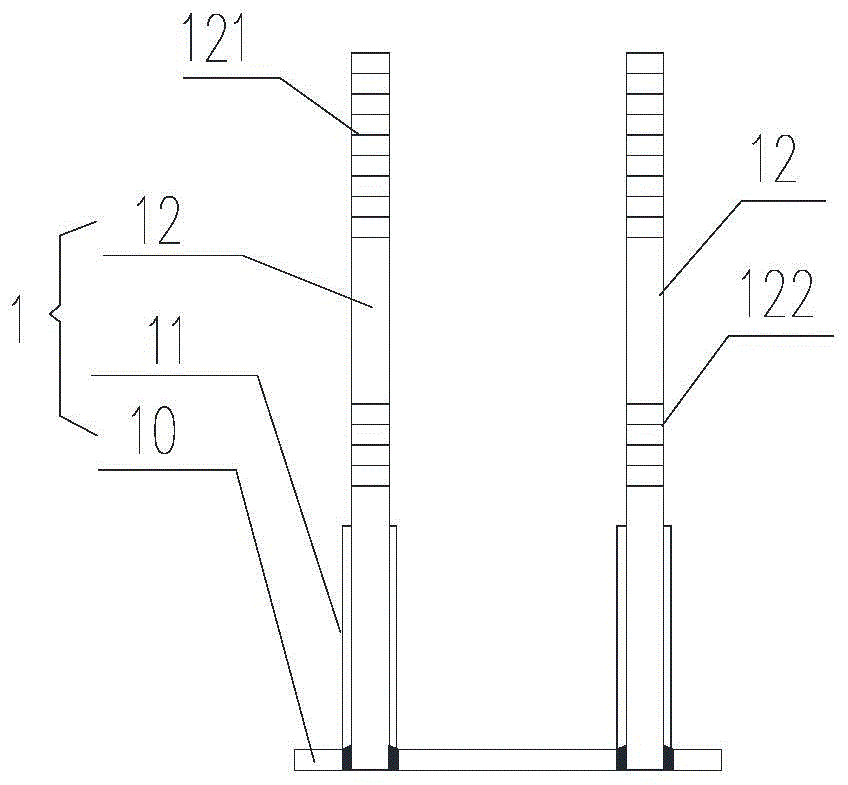

[0026] Such as figure 1 The shown detachable cantilevered steel beam pre-embedded fixing device with horizontal fixed components includes the cantilevered steel beam 5 with an I-shaped cross section, concrete structural parts 6, horizontal fixed components 3, pressure plates 4, The bottom plate 10, at least two screws 12, and first nuts 2 threadedly matched with the screws 12 respectively. The screws 12 are arranged on both sides of the cantilever steel beam 5, and the screws 12 are arranged vertically and spaced apart, and the components are fixed horizontally One end of 3 is detachably connected with the screw 12, the other end of the horizontal fixing assembly 3 is press-fitted with the side surface of the cantilever steel beam 5 in the horizontal direction, and the lower part of each screw 12 and the bottom plate 10 are embedded in the concrete structure 6 , The bottom plate 10 is fixed to the bottom end of each screw 12, the top end of each screw 12 passes through the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com