Servo motor with protection structure

A servo motor and protective structure technology, applied in the field of servo motors, can solve problems such as weak protection, demagnetization, and inability to solve demagnetization, and achieve the effect of offsetting torque, increasing heat dissipation, and facilitating alignment and compensation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

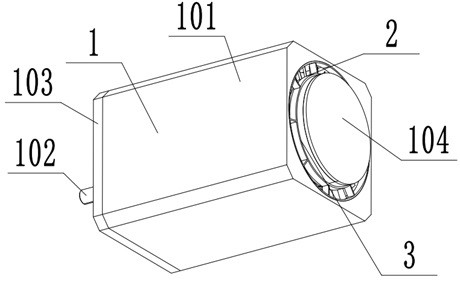

[0025] Example: as Figure 1-Figure 8 The shown servo motor with a protective structure includes a motor body assembly 1 and a heat dissipation and cooling assembly 2 , and the heat dissipation and cooling assembly 2 is installed inside the motor body assembly 1 .

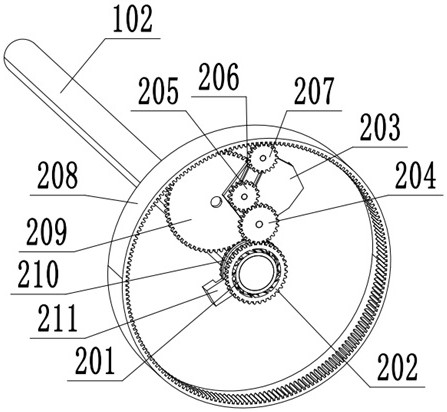

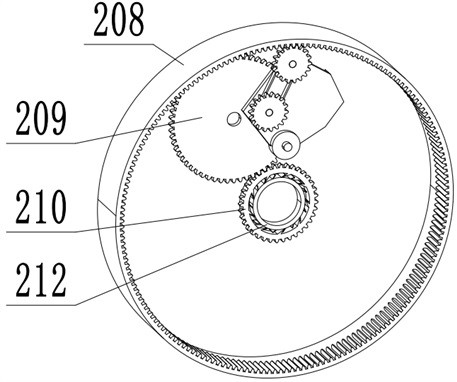

[0026] The motor body assembly 1 includes a motor shaft 102 and a rear base 105. The motor shaft 102 is rotatably mounted on the rear base 105; the heat dissipation and cooling assembly 2 includes a rear inner ratchet 201, a rear outer ratchet 202, a front inner ratchet 212, and a front end. The outer ratchet 210, the rear gear set, the outer gear ring 208, the large gear 209, the rear cooling fan 213, the rear gear set, the outer gear ring 208, and the large gear 209 are all rotatably installed on the rear base 105. The inner ratchet wheel 201 at the end and the inner ratchet wheel 212 at the front end are stacked and fixed on the motor shaft 102. The inner ratchet wheel 201 at the rear end, the outer ratchet whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com