On-line identification method of photographic rotational speed of rotating equipment

A technology of rotating equipment and identification method, applied in the direction of devices using optical methods, etc., can solve problems such as inability to stop, and achieve the effect of ensuring normal operation and overcoming inability to stop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

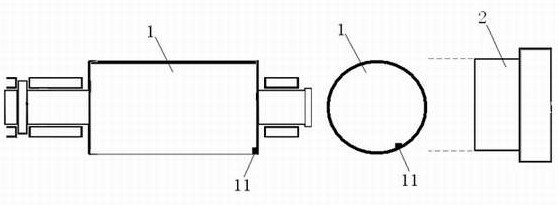

[0023] Example figure 1 with figure 2 As shown, the photographic rotating speed online identification method of rotating equipment of the present invention comprises the following steps:

[0024] Step 1. Set up a camera system 2 with continuous shooting function on one side of the equipment rotating body 1, and at the same time identify a feature point 11 on the outer edge of the equipment rotating body 1;

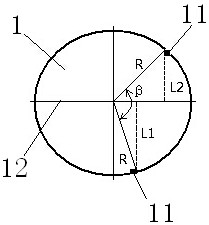

[0025] Step 2: Set the continuous shooting speed of the camera system 2 to 5 frames per second, and take pictures of the rotating body 1, take the first and second photos, and the angle that the rotating body 1 turns within 1 / 5 second is The angle β between the feature point 11 in the first photo and the feature point 11 in the second photo along the direction of rotation plus n times 360 degrees, where n=0,1,2,3,4... ;

[0026] Step 3: Calculate the included angle β by measuring the vertical distance from the feature point 11 to the axis 12 in the photograph and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com