Slide opening and hinge opening two-purpose window structure

A dual-purpose, sliding-to-open technology, applied in the layout of wing sashes, door/window fittings, building structures, etc., can solve the problems of inability to maintain the strength of the square frame structure, blocking, inclination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

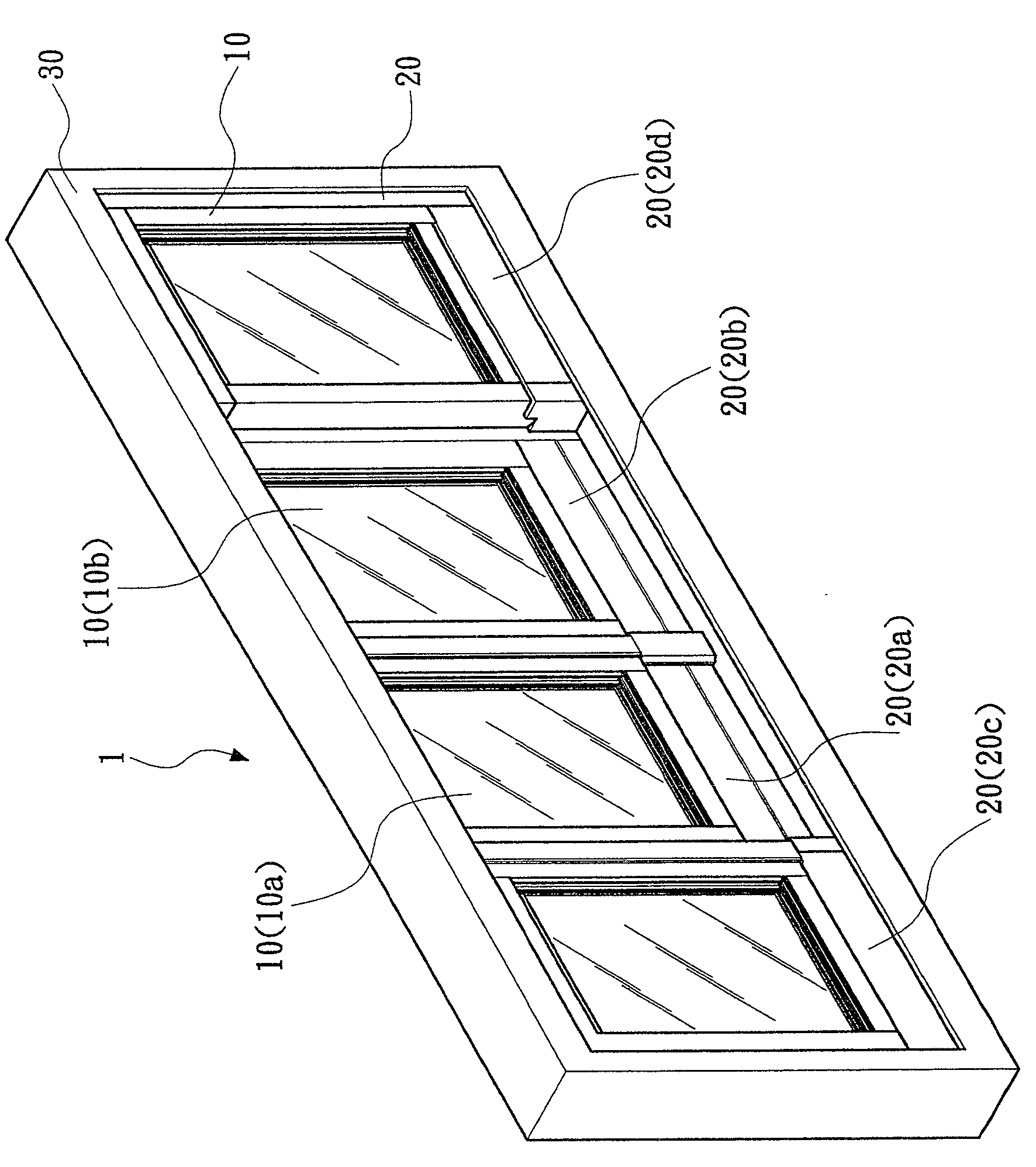

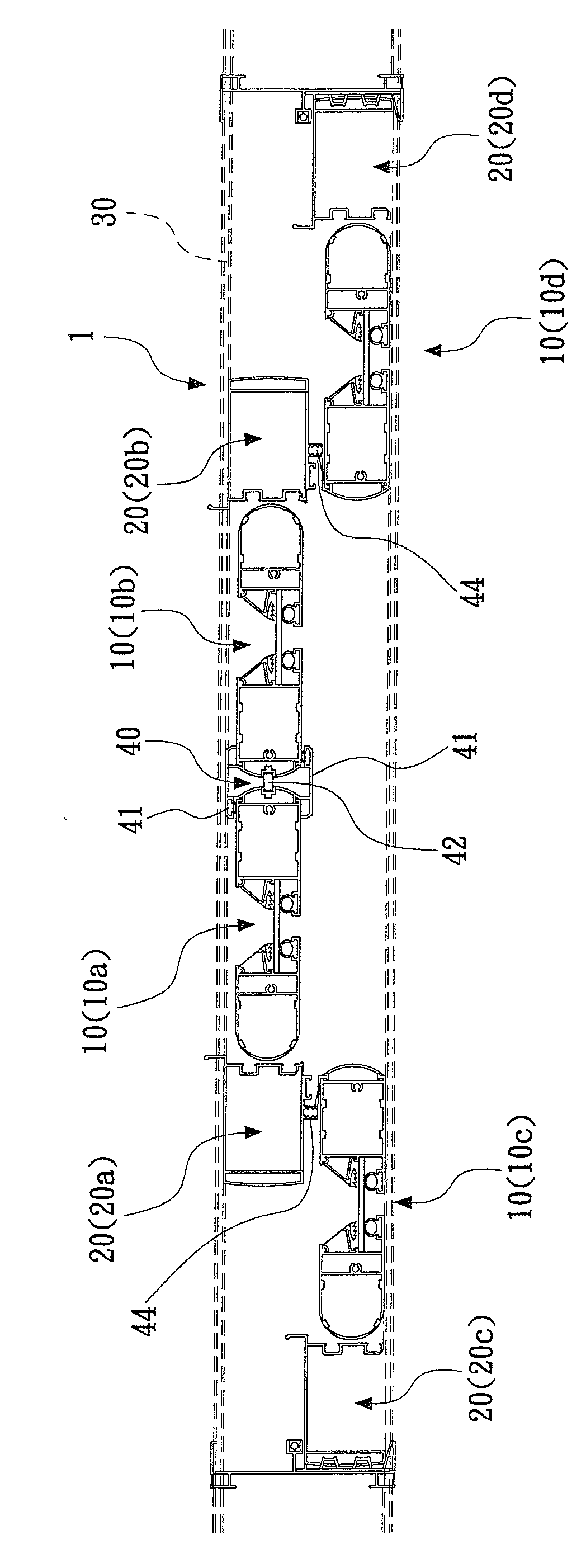

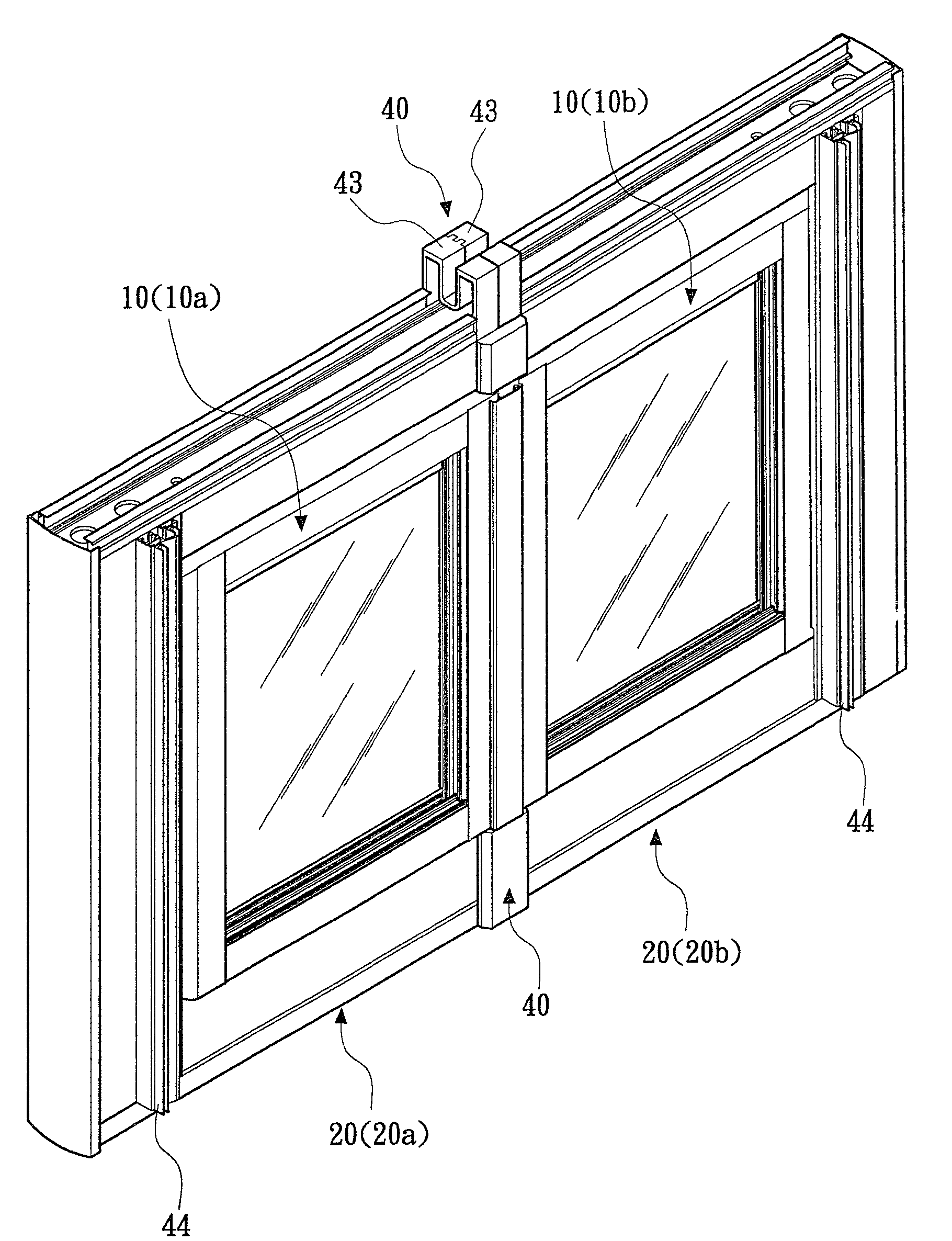

[0016] refer to figure 1 The shown two-track four-window split window assembly 1 of the present invention, the window assembly 1 includes: several inner windows 10, and each inner window 10 is pivotally connected to a C-shaped middle frame 20, all the middle frames 20 are set in the upper and lower tracks of an outer frame 30, and in the figure, the outer frame 30 is provided with inner and outer tracks, and the inner and outer tracks are respectively provided with left and right tracks. Each two pieces are the C-shaped middle frame 20 and the inner window body 10 that are split, wherein, the two C-shaped middle frames 20a, 20b and the inner window body 10a, 10b are inner rails (near indoor), and the other two C-shaped The frame 20c, 20d and the inner window 10c, 10db are on the outer track (nearly outside) in the model. Please also see figure 2 , image 3 , Figure 4 , Figure 5 As shown, a waterproof device 40 is provided at the junction of the two C-shaped middle fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com