A long-period structure reinforced magnesium alloy semi-solid slurry and its preparation method

A semi-solid slurry and reinforced magnesium alloy technology, which is applied in the field of metal materials, can solve the problem of semi-solid slurry research on Mg-Ni-RE magnesium alloy with long-period structural reinforcement that has not yet been found, and achieves no component pollution and easy process Good effect of control and ingredient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

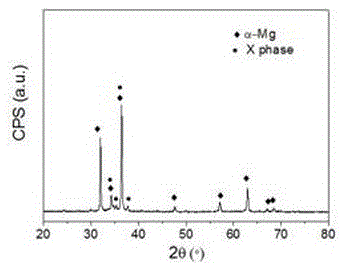

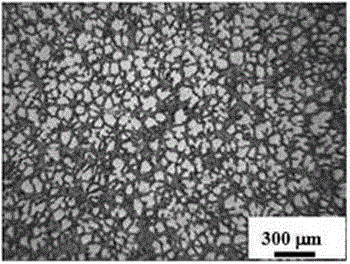

[0021] Example: Mg-Gd-Nd-Ni magnesium alloy semi-solid slurry, the slurry contains the following components (by weight percentage): 86.7% magnesium, 2.2% nickel, 5.8% gadolinium, 5.3% neodymium.

[0022] In the first step, according to the alloy composition of 86.7% magnesium, 2.2% nickel, 5.8% gadolinium, and 5.3% neodymium, magnesium, nickel, and rare earth gadolinium and neodymium raw materials are prepared. The purity of the magnesium, nickel, gadolinium, and neodymium raw materials used is above 99.9%. , Nickel, gadolinium, and neodymium are small particles, the size of which is less than 1mm.

[0023] In the second step, put the raw material of the first step into a graphite crucible and melt it in a high-frequency induction heating furnace. Realize the slow heating of raw materials until they are melted to obtain master alloy ingots.

[0024] In the third step, the above-mentioned master alloy ingot was put into a stainless steel crucible, reheated to 600° C. in a resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com