Low-threshold low-viscosity nematic phase liquid crystal material as well as preparation method and applications thereof

A liquid crystal material, low viscosity technology, used in liquid crystal materials, chemical instruments and methods, instruments, etc., can solve the problems of high viscosity and small dielectric anisotropy, and achieve low operating voltage, low threshold voltage and low viscosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

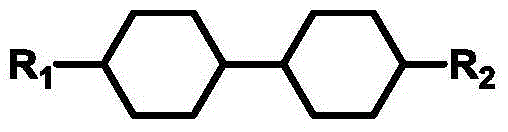

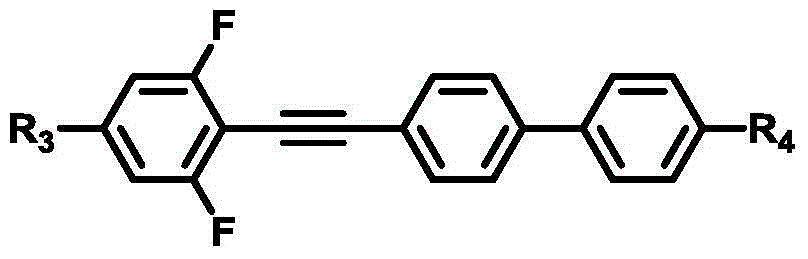

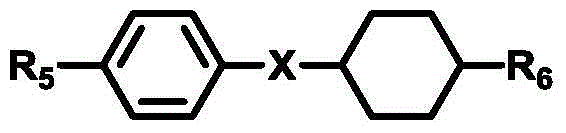

[0045] The liquid crystal material consists of 40.24% component A (A-1: R 1 =C 3 h 7 , R 2 =C 2 h 3 34.15%; A-2: R 1 =C 3 h 7 , R 2 =C 5 h 11 2.85%; A-3: R 1 =OC 2 h 5 , R 2 =C 5 h 9 3.24%), 36.21% of component B (B-1: R 1 =C 2 h 5 , R2 =C 3 h 7 11.23%; B-2: R 1 =C 2 h 5 , R 2 =C 4 h 9 8.64%; B-3: R 1 =C 3 h 9 , R 2 =C 4 h 9 8.78%; B-4: R 1 =C 3 h 9 , R 2 =C 2 h 5 Accounting for 7.56%), 11.55% of component C (C-1: R 1 =OC 4 h 9 , R 2 =C 3 h 7 2.98%; C-2: R 1 =OC 2 h 5 , X=C 2 h 4 , R 2 =C 3 h 7 2.87%; C-3: R 1 =CH 3 , X=C 6 h 12 , R 2 =C 2 h 3 2.67%; C-4: R 1 =F,X=C 6 h 12 , R 2 =C 3 h 7 Accounting for 3.03%), 5.93% of component D (D-1: R 1 =CN,R 2 =C 2 h 3 5.57%; D-2: R 1 = F, R 2 =C 6 h 12 -C 2 h 3 0.09%; D-3: R 1 = F, R 2 =C 6 h 12 -C 2 h 5 Accounting for 0.27%), 3.06% of component E (E: R 1 =C 3 h 7 , R 2 =C 3 h 7 Accounting for 3.06%), 2.68% of component F (F: R 2 =C 4 h 7 2.68%), 0.3...

Embodiment 2

[0053] The liquid crystal material consists of 37.92% component A (A-1: R 1 =C 3 h 7 , R 2 =C 2 h 3 31.37%; A-2: R 1 =C 3 h 7 , R 2 =C 5 h 11 3.91%; A-3: R 1 =OC 2 h 5 , R 2 =C 5 h 9 2.64%), 37.89% of component B (B-1: R 1 =C 2 h 5 , R 2 =C 3 h 7 12.47%; B-2: R 1 =C 2 h 5 , R 2 =C 4 h 9 9.57%; B-3: R 1 =C 3 h 9 , R 2 =C 4 h 9 8.62%; B-4: R 1 =C 3 h 9 , R 2 =C 2 h 5 accounted for 7.23%), 9.63% of component C (C-1: R 1 =OC 4 h 9 , R 2 =C 3 h 7 2.75%; C-2: R 1 =OC 2 h 5 , X=C 2 h 4 , R 2 =C 3 h 7 2.23%; C-3: R 1 =C 2 h 5 , X=C 6 h 12 , R 2 =C 2 h 3 2.14%; C-4: R 1 =C 2 h 5 , X=C 6 h 12 , R 2 =C 3 h 7 accounted for 2.51%), 8.15% of component D (D-1: R 1 = F, R 2 =C 2 h 3 5.88%; D-2: R 1 = F, R 2 =C 6 h 12 -C 2 h 3 Accounting for 2.27%), 3.45% of component E (E: R 1 =C 3 h 7 , R 2 =C 3 h 7 Accounting for 3.45%), 2.96% of component F (F: R 2 =C 4 h 7 Accounting for 2.96%) formed by melt mixing. T...

Embodiment 3

[0062] The liquid crystal material consists of 41.92% component A (A-1: R 1 =C 3 h 7 , R 2 =C 2 h 3 35.49%; A-2: R 1 =C 3 h 7 , R 2 =C 5 h 11 3.91%; A-3: R 1 =OC 2 h 5 , R 2 =C 5 h 9 Accounting for 2.52%), 35.45% of component B (B-1: R 1 =C 2 h 5 , R 2 =C 3 h 7 10.38%; B-2: R 1 =C 2 h 5 , R 2 =C 4 h 9 9.31%; B-3: R 1 =C 3 h 9 , R 2 =C 4 h 9 8.57%; B-4: R 1 =C 3 h 9 , R 2 =C 2 h 5 accounted for 7.19%), 12.17% of component C (C-1: R 1 =OC 4 h 9 , R 2 =C 3 h 73.36%; C-2: R 1 =OC 2 h 5 , X=C 2 h 4 , R 2 =C 3 h 7 2.84%; C-3: R 1 =C 2 h 5 , X=C 6 h 12 , R 2 =C 2 h 3 2.18%; C-4: R 1 =C 2 h 5 , X=C 6 h 12 , R 2 =C 3 h 7 3.09%), 9.29% of component D (D-1: R 1 = F, R 2 =C 2 h 3 6.98%; D-2: R 1 = F, R 2 =C 6 h 12 -C 2 h 3 accounted for 2.31%), 1.87% of component G (G: R 1 =C 3 h 7 Accounting for 1.87%) formed by melt mixing. The molecular structure formula and ratio of each component compound are shown in T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com