Ultraviolet-curable pollution-resistant coating

An ultraviolet light and stain-resistant technology, applied in the field of coatings, can solve the problems of oil-based pen imprinting, limited application, poor stain resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

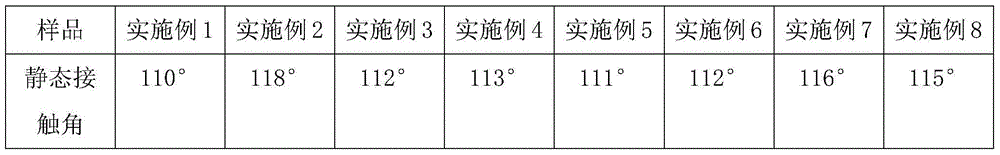

Examples

Embodiment 1

[0019] UV-curable stain-resistant coatings, in parts by weight, consist of the following components: 60 parts of modified epoxy acrylate Hengguang 6101, 58 parts of epoxy acrylate, 20 parts of polyurethane acrylate Hengguang 7402, polyester modified acrylic acid Ester Hengguang 5212 30 parts, dipentaerythritol pentaacrylate 12 parts, tripropylene glycol diacrylate 13 parts, anti-pollution photocuring additive polydimethylsiloxane 7 parts, photoinitiator 1-hydroxycyclohexylphenylmethicone 1 part of ketone, 32 parts of diluent pentaerythritol tetraacrylate, 42 parts of acrylate leveling agent MONENG-11542. Put each component into the reaction vessel according to their respective parts by weight, ultrasonically disperse for 60 minutes, heat to 75°C, stir and disperse at high speed for 3.5 hours.

Embodiment 2

[0021] UV-curable stain-resistant coatings, in parts by weight, consist of the following components: 66 parts of modified epoxy acrylate Hengguang 6106, 62 parts of epoxy acrylate, 23 parts of polyurethane acrylate Hengguang 7402-6, modified polyester 34 parts of permanent acrylate Hengguang 5218, 15 parts of dipentaerythritol pentaacrylate, 18 parts of tripropylene glycol diacrylate, 8 parts of anti-pollution photocuring auxiliary polymethylphenylsiloxane, photoinitiator 2-methyl- 5 parts of 2-(4-morpholinyl)-1-[4-(methylthio)phenyl]-1-propanone, 37 parts of diluent pentaerythritol hexaacrylate, 3 parts of acrylate leveling agent MONENG-1154 . Add each component into the reaction vessel according to their respective parts by weight, ultrasonically disperse for 65 minutes, heat to 80°C, and disperse with high-speed stirring for 5.5 hours.

Embodiment 3

[0023] UV-curable stain-resistant coatings, in parts by weight, consist of the following components: 75 parts of modified epoxy acrylate Hengguang 6116, 68 parts of epoxy acrylate, 25 parts of polyurethane acrylate Hengguang 7402, polyester modified acrylic acid Ester Hengguang 5212 35 parts, dipentaerythritol pentaacrylate 18 parts, tripropylene glycol diacrylate 23 parts, anti-pollution photocuring auxiliary agent organo-modified polysiloxane 8 parts, photoinitiator 2-hydroxy-2-methyl Base-1-[4-(2-hydroxyethoxy)phenyl]-1-acetone 8 parts, diluent hydroxyethyl acrylate 39 parts, acrylate leveling agent MONENG-1154 4 parts. Add each component into the reaction vessel according to their respective parts by weight, ultrasonically disperse for 70 minutes, heat to 85°C, and disperse with high-speed stirring for 4 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com