Anticorrosive paint for power cables

A technology for anti-corrosion coatings and power cables, applied in anti-corrosion coatings, coatings, plastic/resin/wax insulators, etc. The effect of preventing acid, alkali, salt and damp heat, reducing safety hazards and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A kind of anticorrosion coating for power cable, it is prepared according to the following method:

[0018] Step 1) Preparation of material A: sequentially add acrylic acid, N-methylpyrrolidone, polyoxyethylene lauryl ether, emulsified silicone oil and phthalate into the reactor, and stir at 1000 rpm for 5 minutes to obtain material A; Wherein, the weight ratio of acrylic acid, N-methylpyrrolidone, polyoxyethylene lauryl ether, emulsified silicone oil and phthalate is 10:6:5:3:1;

[0019] Step 2) Preparation of material B: send borax, white graphite and aluminum tripolyphosphate to a ball mill, grind to a powder with a particle size of 500 mesh, then mix the powder with sodium silicate evenly, which is material B; wherein, borax, sodium The weight ratio of water glass, white graphite and aluminum tripolyphosphate is 3:2:1:1;

[0020] Step 3) preparing material C: mixing nano silica gel powder and nano titanium dioxide according to a weight ratio of 1:1, which is materi...

Embodiment 2

[0025] A kind of anticorrosion coating for power cable, it is prepared according to the following method:

[0026] Step 1) Preparation of material A: sequentially add acrylic acid, N-methylpyrrolidone, polyoxyethylene lauryl ether, emulsified silicone oil and phthalate into the reactor, and stir at 1000 rpm for 5 minutes to obtain material A; Wherein, the weight ratio of acrylic acid, N-methylpyrrolidone, polyoxyethylene lauryl ether, emulsified silicone oil and phthalate is 10:6:5:3:1;

[0027] Step 2) Preparation of material B: send borax, white graphite and aluminum tripolyphosphate to a ball mill, grind to a powder with a particle size of 500 mesh, then mix the powder with sodium silicate evenly, which is material B; wherein, borax, sodium The weight ratio of water glass, white graphite and aluminum tripolyphosphate is 3:2:1:1;

[0028] Step 3) preparing material C: mixing nano silica gel powder and nano titanium dioxide according to a weight ratio of 1:1, which is materi...

Embodiment 3

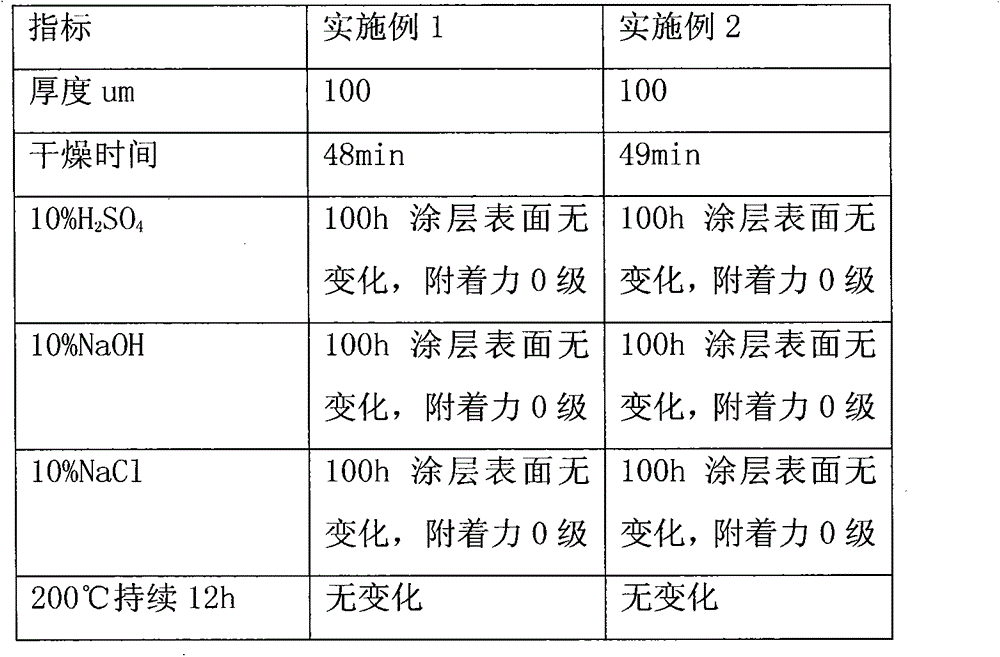

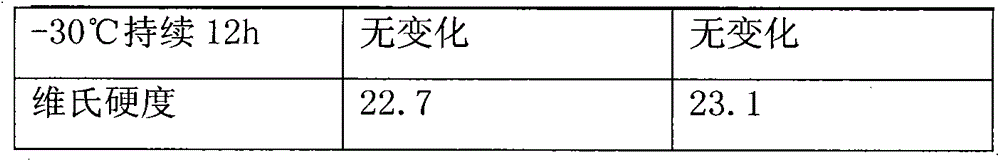

[0033] Use the cable surface performance parameter determination of the anticorrosion paint prepared by embodiment 1 and embodiment 2, specifically refer to table 1:

[0034] Table 1

[0035]

[0036]

[0037] From the data in Table 1, it can be found that the anti-corrosion coatings prepared in Example 1 and Example 2 of the present invention have better performance, can effectively prevent the corrosion of acid-base salts, and have better high temperature resistance, flame retardancy and mechanical properties .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com