Polymerization preparation method of similar nano inorganic powder material modified styrene resin

A styrenic resin and nano-inorganic technology, which is applied in the field of polymerization and preparation of styrenic resin modified by nano-inorganic powder materials to achieve the effects of good product performance, good flexibility and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

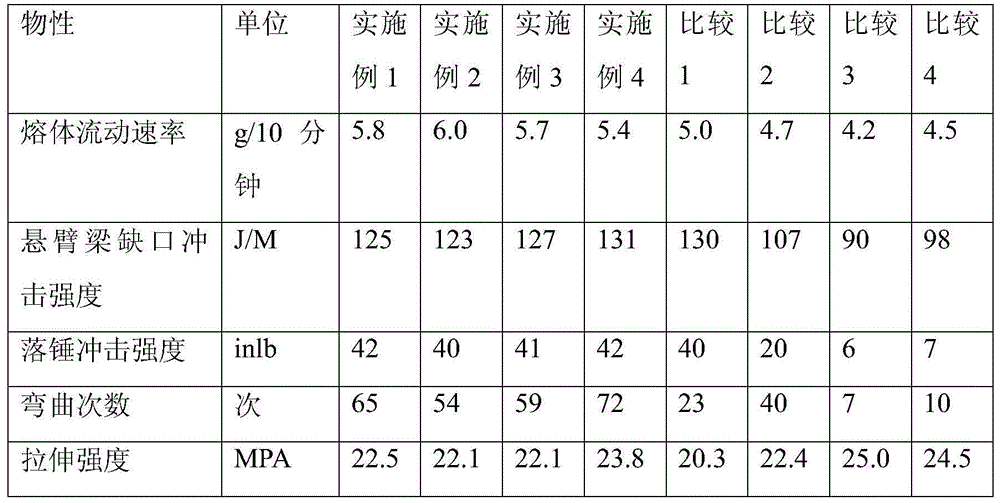

Examples

Embodiment 1

[0024] 3% by weight of mineral oil and 9% by weight of low cis polybutadiene rubber in the feed liquid are dissolved in 88% by weight of styrene monomer to prepare a rubber solution and then sent to the first stage as the feed liquid In a continuous stirred tank reactor, thermal initiation is used, and the polymerization is carried out at a reaction temperature of 115-130°C to reach a conversion rate of 30%, and then it is sent to the subsequent three stages of plug flow which gradually increases at a subsequent reaction temperature of 130-175°C. Reactor polymerization, in which the average particle size of 1% by weight of the feed liquid is 200nm barium sulfate, and the average particle size of 1% by weight of the feed liquid is 50nm of silicon oxide and 1% by weight of the feed liquid. Ethylene, mineral oil accounting for 1% by weight of the feed liquid, and ethylbenzene accounting for 1% by weight of the feed liquid are mixed into the second stage plug flow reactor, and the p...

Embodiment 2

[0026] The same reaction conditions as in Example 1, except that the average particle size of 1% by weight of the feed liquid is 200nm barium sulfate and the average particle size of 1% by weight of the feed liquid is 50nm of silica and the amount of silica Styrene with a liquid weight ratio of 1%, mineral oil with a weight ratio of 1% for the feed liquid, and ethylbenzene with a weight ratio of 1% for the feed liquid are mixed and added in the third-stage reactor. See Table 1 for specific physical properties.

Embodiment 3

[0028] The same reaction conditions and powder material addition time as in Example 1, except that the nano-inorganic powder material in Example 1 was changed to 4.9μm ultrafine kaolin and 10μm each accounting for 1% by weight of the feed liquid. Superfine talcum powder. See Table 1 for specific physical properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com