Ceramsite recycled concrete as well as hollow block masonry and preparation method thereof

A technology of recycled concrete and ceramsite, which is applied in the field of building materials, can solve the problems of blank research on recycled concrete and few research on concrete, and achieve the effect of sustainable social development, resource saving and ecological environment protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

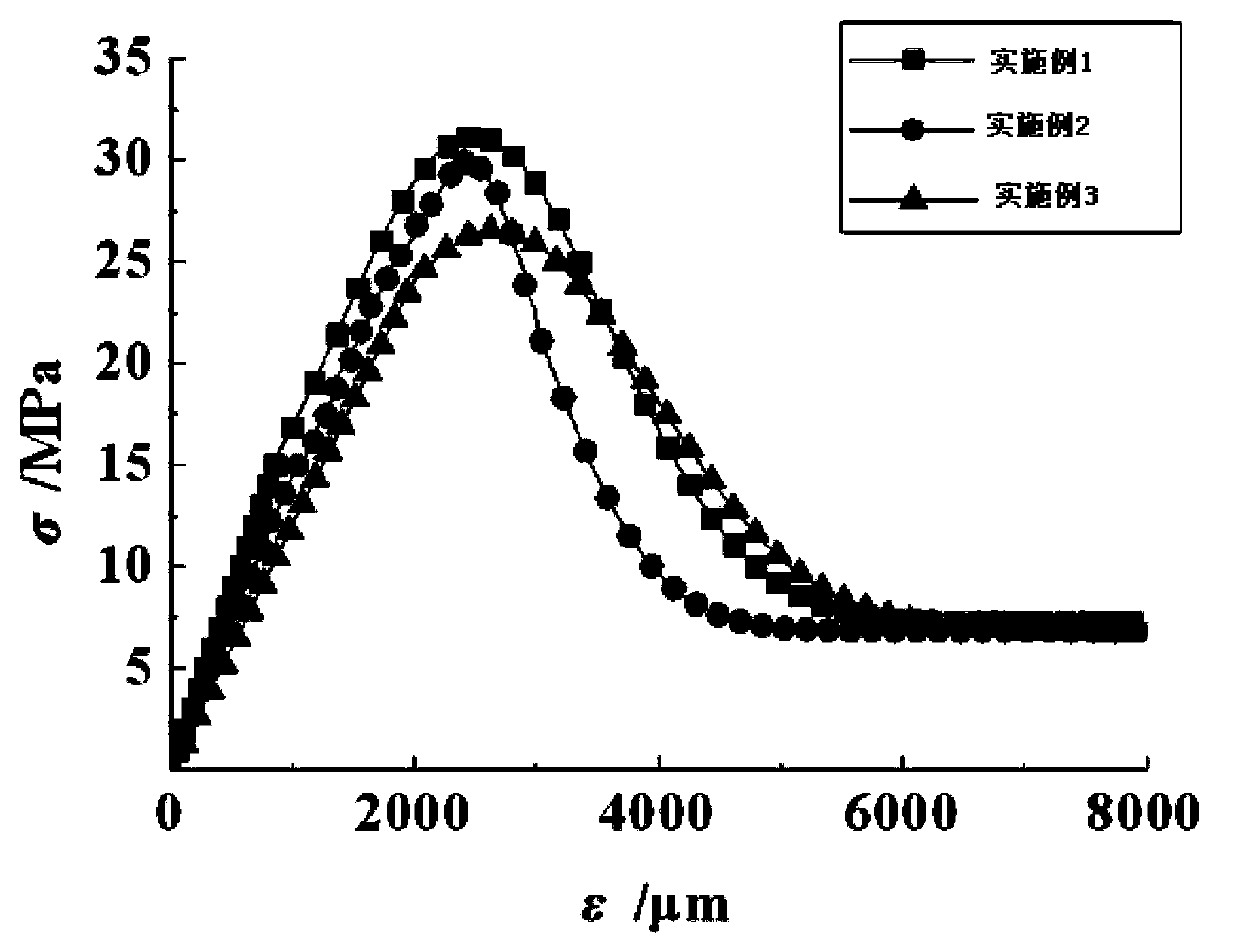

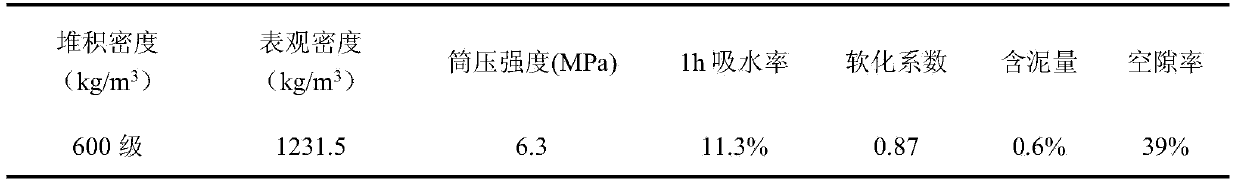

Embodiment 1

[0032] 1.1 The ceramsite recycled concrete of the present invention is made up of the raw material of following weight parts (Kg):

[0033] Ceramsite 360, recycled fine aggregate 860, cement 400, water 200.

[0034] 1.2 The preparation method of ceramsite recycled concrete of the present invention:

[0035] (1) Soak the ceramsite and the regenerated fine aggregate in water for 1 hour, then remove and dry until there is no accumulated water on the surface for later use;

[0036] (2) Mix and stir the pre-wetted ceramsite and regenerated sand for 30 seconds, so that the regenerated sand can fill the voids of the ceramsite, then add cement and stir for 30 seconds, so that the cement is evenly distributed in the coarse and fine aggregates, and finally add water Stir for another 2 minutes to prepare ceramsite recycled concrete.

[0037] 1.3 The method of making hollow block masonry by using the ceramsite recycled concrete of this embodiment:

[0038] (1) For the second mold loadi...

Embodiment 2

[0044] 2.1 The ceramsite recycled concrete of the present invention is composed of the following raw materials in parts by weight (Kg):

[0045] Ceramsite 440, recycled fine aggregate 660, cement 520, water 150.

[0046] 2.2 The preparation method of ceramsite recycled concrete of the present invention:

[0047] (1) Soak the ceramsite and the regenerated fine aggregate in water for 1 hour, then remove and dry until there is no accumulated water on the surface for later use;

[0048] (2) Mix and stir the pre-wetted ceramsite and regenerated sand for 30 seconds, so that the regenerated sand can fill the voids of the ceramsite, then add cement and stir for 30 seconds, so that the cement is evenly distributed in the coarse and fine aggregates, and finally add water Stir for another 2 minutes to prepare ceramsite recycled concrete.

[0049] 2.3 The method of using the ceramsite recycled concrete of this embodiment to manufacture hollow block masonry:

[0050] (1) For the second mo...

Embodiment 3

[0056] 3.1 The ceramsite recycled concrete of the present invention is composed of the following raw materials in parts by weight (Kg):

[0057] Ceramsite 402, recycled fine aggregate 760, cement 400, water 180.

[0058] 3.2 The preparation method of ceramsite recycled concrete of the present invention:

[0059] (1) Soak the ceramsite and the regenerated fine aggregate in water for 1 hour, then remove and dry until there is no accumulated water on the surface for later use;

[0060] (2) Mix and stir the pre-wetted ceramsite and regenerated sand for 30 seconds, so that the regenerated sand can fill the voids of the ceramsite, then add cement and stir for 30 seconds, so that the cement is evenly distributed in the coarse and fine aggregates, and finally add water Stir for another 2 minutes to prepare ceramsite recycled concrete.

[0061] 3.3 The method of using the ceramsite recycled concrete of this embodiment to manufacture hollow block masonry:

[0062] (1) For the second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com