A Construction Method of Subgrade Foam Concrete Filling Technology Adjacent to Existing Subway Facilities

A technology with existing subways and construction methods, applied in roads, buildings, roads, etc., can solve the problems of easy cracking of concrete, restricting widespread use, low strength, etc., to increase stability and safety factor, ensure strength, and improve strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

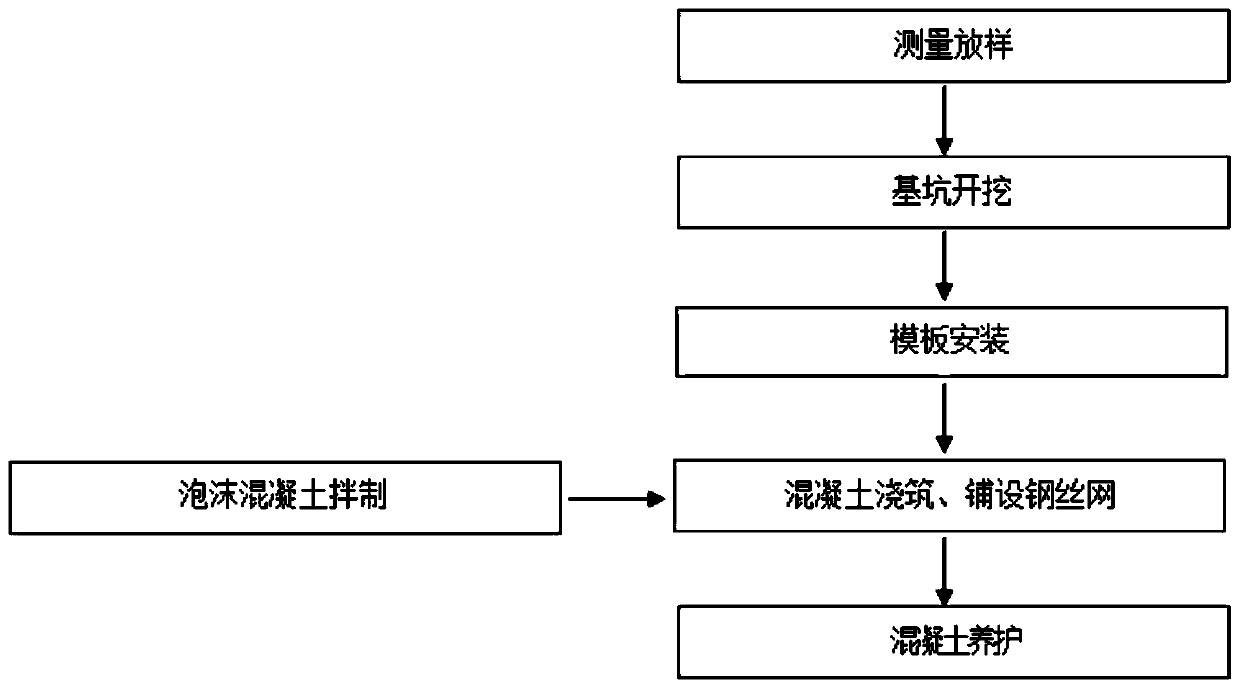

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principles of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

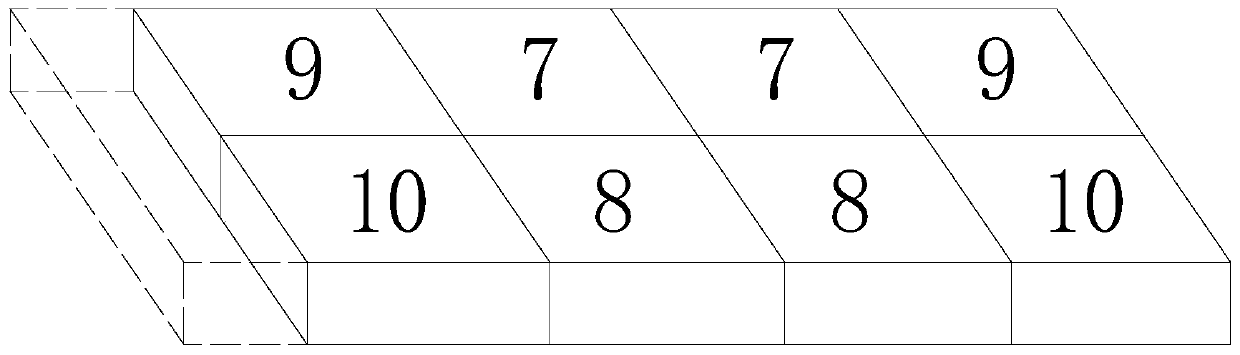

[0028] The invention prepares the foamed concrete by adjusting the mixing ratio to meet its different strength requirements. like image 3 , Figure 4 As shown, the foam concrete is poured in blocks and layers, divided into 4 sections vertically, left and right sections horizontally, and 2 layers vertically. The same layer of foam concrete, the middle part includes the first position 7 and the second position 8, the lateral side of the first position 7 is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com