Sludge and silt sintered brick with clay brick surface layer and preparation method thereof

A technology of clay sintering and sintering bricks, which is applied to home appliances, ceramic products, and other home appliances. It can solve the problems of clay bricks that cannot meet the performance, wall cracking, and easy hollowing of plastering, etc., to improve cracking and cost. Low, the effect of rational allocation of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

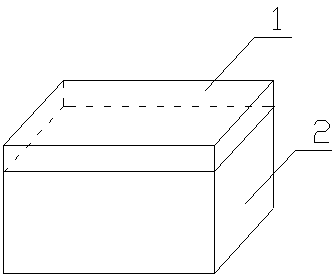

[0040] As shown in the figure, the sintered brick of the present invention includes two layers of brick bodies: clay sintered layer 1 and silt sludge sintered layer 2 . Wherein the thickness of the clay sintered layer is 5mm;

[0041] The clay sintered layer is composed of the following raw materials in mass percentage: 70% clay, 15% cinder and coal gangue, 10% sawdust, 5% rice husk and straw;

[0042] The sludge sludge sintering layer is composed of the following raw materials in mass percentage: 50% river and lake sludge, 20% urban sludge, 15% coal cinder and coal gangue, 10% wood chips, 5% rice husk and straw.

[0043] Among them, coal slag, coal gangue, sawdust, rice husk and straw are crushed, with a particle size of 2.5mm and a water content of 10%.

Embodiment 2

[0045] As shown in the figure, the sintered brick of the present invention includes two layers of brick bodies: clay sintered layer 1 and silt sludge sintered layer 2 . Wherein the thickness of the clay sintered layer is 8mm.

[0046] The clay sintered layer is composed of the following raw materials in mass percentage: 70% clay, 15% cinder and coal gangue, and 15% domestic garbage particles;

[0047] The sludge sludge sintering layer is composed of the following raw materials in mass percentage: 50% river and lake sludge, 20% urban sludge, 15% coal cinder and coal gangue, and 15% domestic garbage particles.

[0048] Among them, the domestic waste particles are selected from sorted combustible organic matter, and the combustible organic matter, coal cinder and coal gangue are crushed, with a particle size of 2.5mm and a moisture content of 10%.

[0049] Product Example 3

[0050] As shown in the figure, the sintered brick of the present invention includes two layers of brick...

Embodiment 4

[0055] As shown in the figure, the sintered brick of the present invention includes two layers of brick bodies: clay sintered layer 1 and silt sludge sintered layer 2 . The thickness of the clay sintered layer is 20mm.

[0056] The clay sintered layer is composed of the following raw materials in mass percentage: 85% clay, 7% cinder and coal gangue, and 8% domestic garbage particles;

[0057] The sludge sludge sintering layer is composed of the following raw materials in mass percentage: 70% river and lake sludge, 15% urban sludge, 7% coal cinder and coal gangue, and 8% domestic garbage particles.

[0058] Among them, the domestic waste particles are selected from sorted combustible organic matter, and the combustible organic matter, coal cinder and coal gangue are crushed, with a particle size of 2.5mm and a moisture content of 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com