High ammonia-nitrogen tail liquid zero-discharge treatment system and high ammonia-nitrogen tail liquid zero-discharge treatment method applied after alkaline etching waste liquid treatment

A technology for etching waste liquid and treatment system, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. high concentration problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

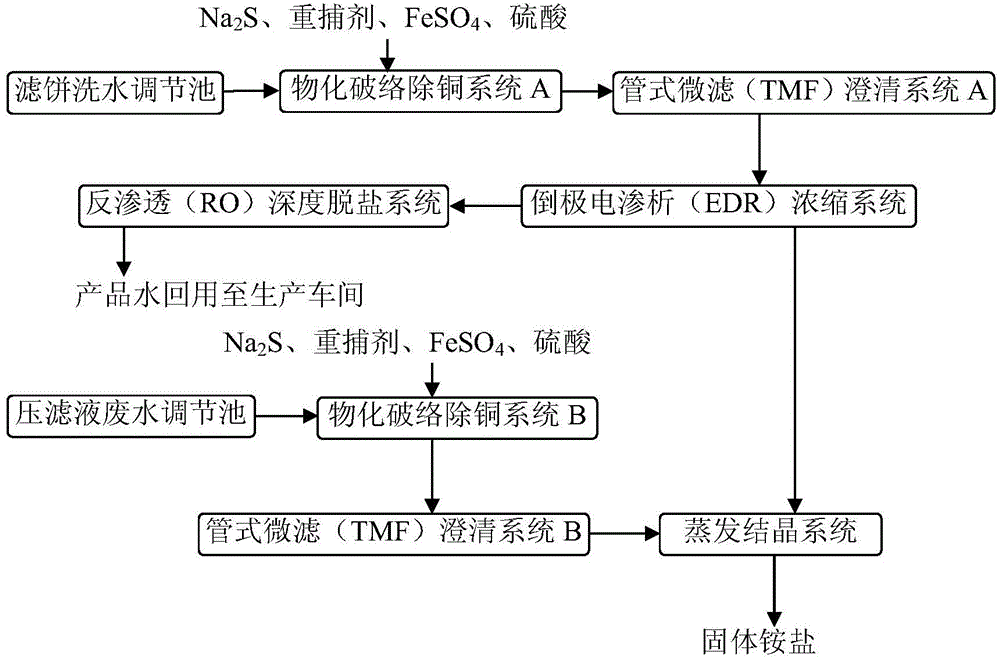

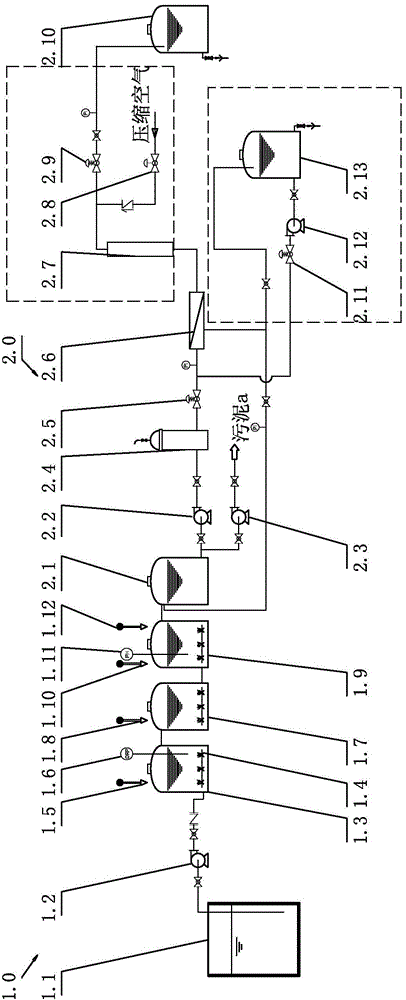

[0035] A zero-emission treatment system for high-ammonia nitrogen tail liquid after alkaline etching waste liquid treatment, the treatment system includes the following subsystems: Physicochemical Decomposition and Copper Removal System 1.0, Tubular Microfiltration (TMF) Clarification System 2.0, Inversion Electroosmosis Extreme (EDR) concentration system 3.0, reverse osmosis (RO) deep desalination system 4.0 and evaporation crystallization system 5.0. In this specific embodiment, the processing capacity is 1-2m 3 / h.

[0036] like figure 1 As shown, the tail liquid after the treatment of alkaline etching waste liquid in PCB enterprises includes press filtrate and filter cake washing water. , in the physical and chemical decomplexation copper removal system 1.0 and the tubular microfiltration (TMF) clarification system 2.0 respectively, and the filter cake washing water is concentrated by the electrodialysis (EDR) concentration system 3.0, and then followed by the physical a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com