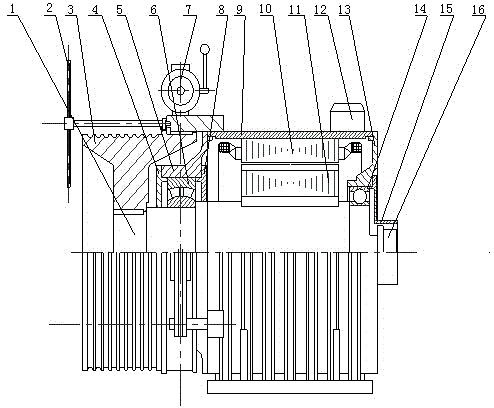

Magnetic-resistance type toothless elevator traction machine

An elevator traction machine, reluctance-type technology, applied in the field of switched reluctance motors, can solve problems such as demagnetization and loss of magnetism, uneven magnetic pole distribution of magnetic steel, and increased cost, so as to reduce vibration and noise, eliminate adverse effects, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

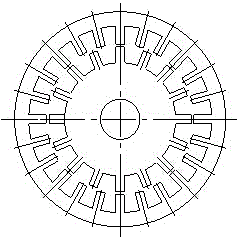

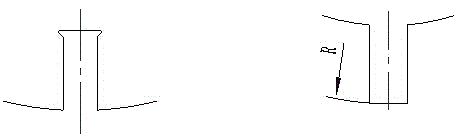

[0039] For the servo switched reluctance motor of the reluctance toothless elevator traction machine, when the rotor is in different positions, the phase inductance L (θ, i) is different, and the energization time of each phase winding can be changed according to the law. The size and waveform of the current produce different speeds and steering, and enter different operating states. The position detection of the controller is a closed loop. It detects the relative position between the stator and the rotor according to the position detector, and conducts the switching elements of the corresponding phase windings according to the given operation command. There is current flowing in the phase winding, and magnetic flux is generated, and the rotor is subjected to the magnetic pulling force generated by the tendency to move to the minimum reluctance position, and it rotates under the action of this force until the salient pole of the rotor turns and is drawn by it. until the attra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com