Four-axel single-tire bearing electric bus

An electric bus and single-tire technology, which is applied to vehicle components, steering mechanisms, steering rods, etc., can solve the problems of inconvenience for passengers to get up and sit, and the large load of a single bridge. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

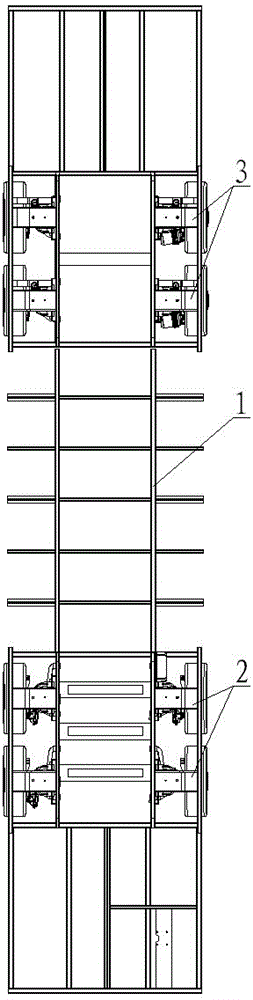

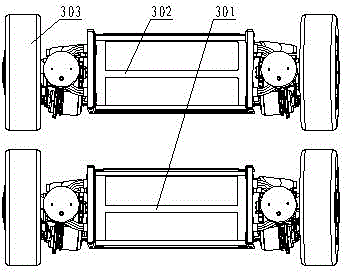

[0023] Such as figure 1 As shown, a four-axle single-tire electric bus includes a chassis 1, a steering mechanism 2 and a driving mechanism 3, wherein the steering mechanism 2 and the driving mechanism 3 are fixed on the chassis 1, and the steering mechanism 2 is located on the driving mechanism 3 front side. The steering mechanism 2 of the present embodiment includes a first steering axle 201 and a second steering axle 202, the first steering axle 201 and the second steering axle 202 are arranged laterally and parallel to each other, and the first steering axle 201 and the second steering axle 202 are horizontal The heights are the same and there is a certain distance in the longitudinal direction. Both sides of the first steering axle 201 and the second steering axle 202 are provided with steering wheels 207 . The drive mechanism 3 of the present embodiment includes a drive axle, an electric drive system and a drive wheel 303, wherein the drive axle includes a first drive a...

Embodiment 2

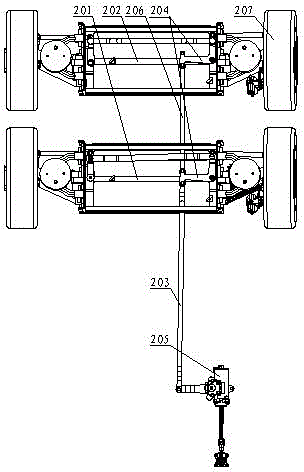

[0026] Such as figure 2 As shown, this embodiment makes the following further limitations on the basis of Embodiment 1: the steering mechanism 2 of this embodiment also includes a longitudinal tie rod 203, a steering booster 205 and an intermediate tie rod 206, wherein the first steering axle 201 and The second steering bridge 202 is connected with a steering rocker arm 204, and the trailing rod 203 and the intermediate tie rod 6 are arranged longitudinally and coaxially. Both ends of the arm 204 and the middle tie rod 206 are respectively connected to the steering rocker arm 204 on the first steering axle 201 and the steering rocker arm 204 on the second steering axle 202 .

[0027] When this embodiment is applied, the steering booster 205 drives the longitudinal tie rod 203 to move, the longitudinal tie rod 203 transmits power to the steering rocker arm 204 on the first steering axle 201, and the steering rocker arm 204 on the first steering axle 201 drives the intermediate...

Embodiment 3

[0029]This embodiment makes the following further limitations on the basis of Embodiment 2: the steering rocker arm 204 of this embodiment includes a horizontally arranged transverse connecting plate and a longitudinally arranged longitudinal connecting plate, wherein the front end of the longitudinal connecting plate and the transverse connecting plate Connection, the longitudinal connecting plate is connected with the transverse connecting plate to form an "L" shape as a whole. In order to increase the structural strength of the steering rocker arm 204, the transverse connection plate and the longitudinal connection plate of the steering rocker arm 204 are integrated into one body in this embodiment. In this embodiment, the steering rocker arm 204 on the first steering bridge 201 is arranged on the first steering bridge 201 through the limit pin passing through the connecting portion of the transverse connecting plate and the longitudinal connecting plate, and the steering ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com