A mesoporous hemostatic particle with antibacterial properties and its preparation method and application

A technology of hemostatic granules and hemostatic powder, applied in the field of biomaterials, can solve the problems of powder scattering, adhesion, aggregation and hygroscopicity, high debridement difficulty, and increased debridement difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The preparation method of antibacterial hemostatic granule of the present invention, comprises the following steps:

[0059]a) Dissolve the surfactant in a polar solvent, add the silver source and then add the silicon source, adjust the pH of the system to 2-10, obtain the sol through the sol-gel process, age and dry the sol to obtain silver-containing silicon Xerogel-based hemostatic powder, optionally, mixing the obtained hemostatic powder with an auxiliary agent to obtain a powder;

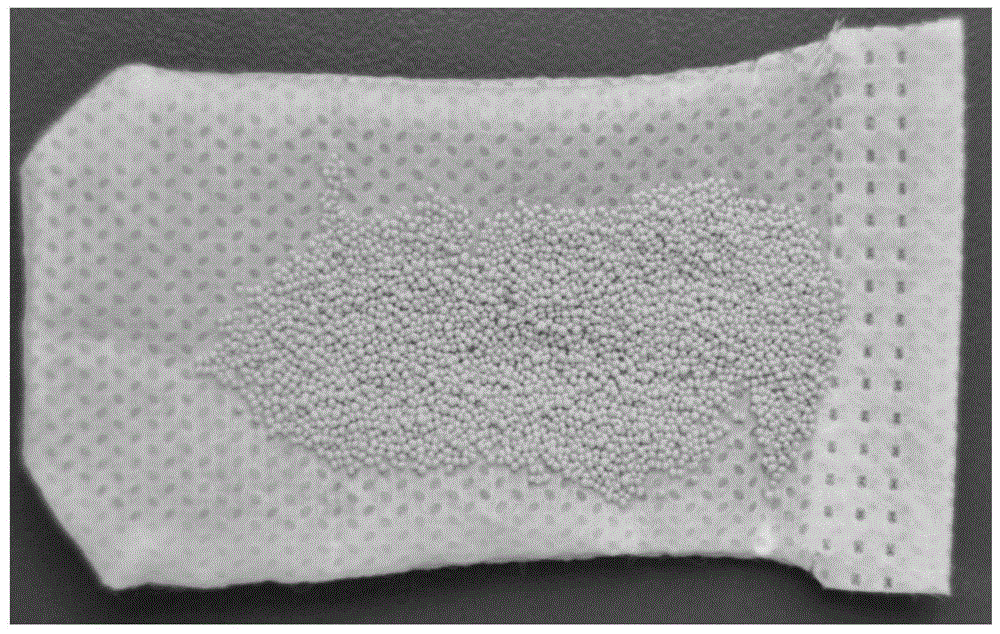

[0060] (b) Spray the binder solution on the hemostatic powder or powder obtained in step (a) in a granulator, then granulate, and dry and sieve to obtain a hemostatic particle base of 500 microns to 700 microns;

[0061] (c) sintering and shaping the hemostatic particle base obtained in step (b) to obtain antibacterial hemostatic particles with an average particle size of 450 microns-700 microns,

[0062] in,

[0063] The silver source is one or a combination of two or more of silver n...

Embodiment 1

[0102] Preparation of Antibacterial Hemostatic Granules

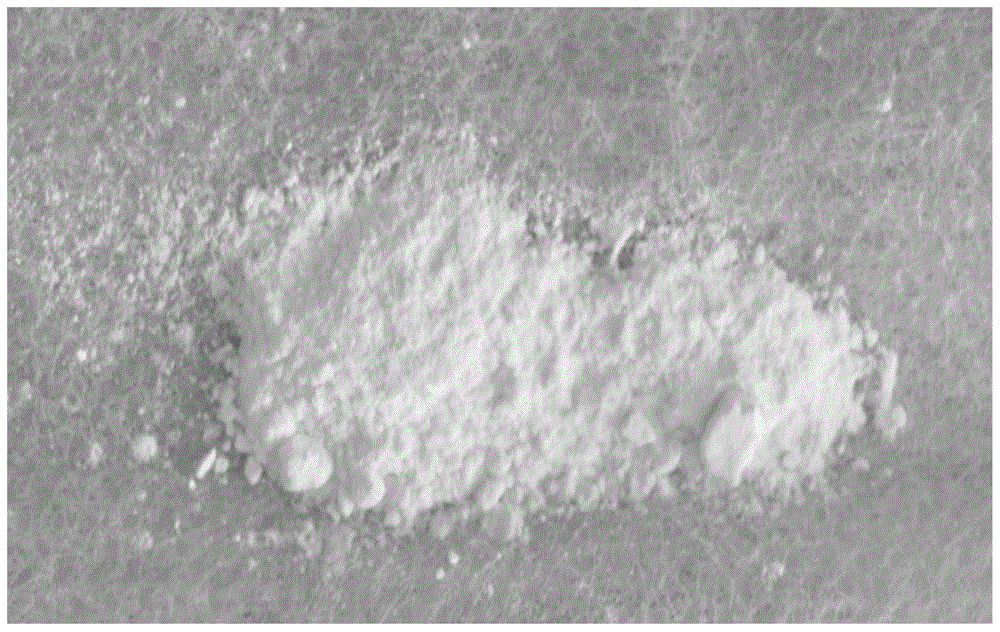

[0103] Dissolve 3g of P123 (polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer) in 140g of deionized water, mix well, place in a water bath at 35°C, add 1g of AgNO 3 Keep stirring for 4-5 hours in the dark, then add 10g TEOS (tetraethyl orthosilicate) drop by drop, adjust the pH value to about 2 with nitric acid, stir evenly, raise the temperature to 60°C and continue stirring, and react for 5 hours to obtain a stable and transparent The sol, the sol is aged, washed and dried to constant weight to obtain a silicon dioxide powder containing Ag containing P123 ( figure 1 ).

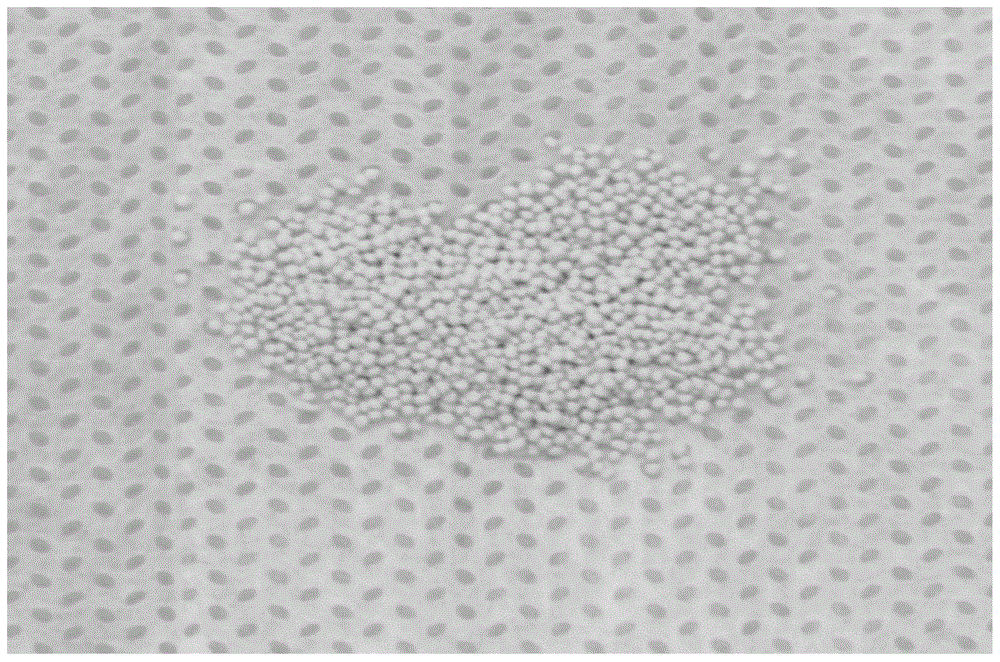

[0104] Mix 10g of silicon dioxide powder containing silver and P123 with 1g of starch to obtain a powder, add it to a swash plate granulator, spray about 10g of an aqueous solution of 5% (w / w) natural clay, and make the powder and aqueous solution In close contact with each other, the spheronizing speed is 80rpm, and the s...

Embodiment 2

[0109] Preparation of Antibacterial Hemostatic Granules

[0110] Dissolve 20g of CTAB (cetyltrimethylammonium bromide) in 400g of deionized water, mix well, place in a water bath at 35°C, add 9g of AgNO 3 Keep stirring for 4-5 hours after avoiding light, then add 75g TEOS (tetraethyl orthosilicate) drop by drop, adjust the pH value to about 10 with NaOH, stir evenly, raise the temperature to 60°C and continue stirring, and react for 5 hours to obtain a stable and transparent The sol is aged, washed, and dried to constant weight to obtain a silicon dioxide powder containing Ag and CTAB.

[0111] 0.5g carboxymethyl cellulose is dissolved in water to prepare 2.5% (w / w) binder solution liquid material, 10g silicon dioxide powder containing Ag and CTAB is added in the swash plate granulator, sprayed into the solution There is about 30g of liquid material of carboxymethyl cellulose, so that silicon dioxide and liquid material are in close contact with each other to form agglomerate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com