Method for improving fermentability and nutritional property of gluten protein-free dough

A gluten- and protein-free technology, which is applied in the directions of dough processing, pre-baking dough processing, baking, etc., can solve the problems of limited improvement in the fermentation performance of gluten-free dough, and achieve easy industrial production, simple preparation method, and improved performance. The effect of the ability to hold the gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The addition amount of carboxypropyl methylcellulose in gluten-free fermented dough of embodiment 1

[0033] Take 140g of potato starch, 40g of whole potato powder, and 20g of whey protein concentrate, mix well, and dissolve 0, 0.15, 0.25, 0.75, 1.0, 1.5, 2.0g of carboxypropyl methylcellulose (HPMC) in 100g of 50°C water respectively , then add the above mixture and stir at a low speed of 80-90rpm for 5min to mix evenly, then stir at a medium speed of 110-120rpm for 5min; weigh 1.0% yeast and dissolve it in 50g of water, activate it at 35°C for 10min and add it to the above mixture, stir at a medium speed of 110-120rpm 5min until the dough is formed, then fermented at 36°C and 85% humidity for 50min.

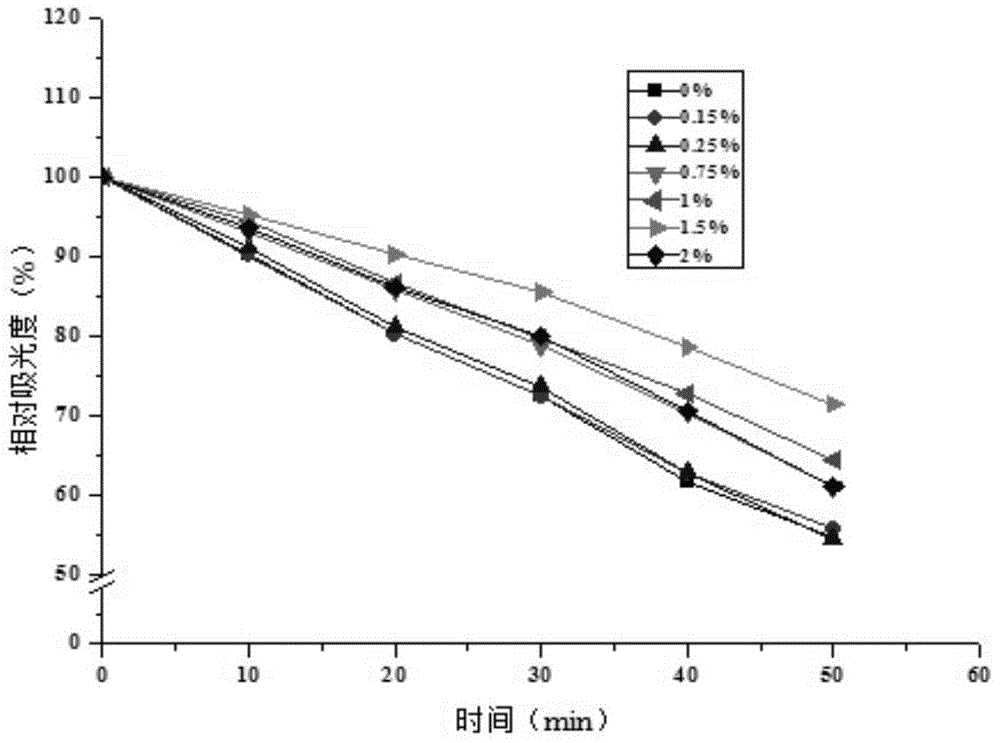

[0034] The dough made by the above method, along with the increase of HPMC addition, the water absorption of dough increases, the viscosity increases, and the consistency of dough increases (the change of turbidity reduces, figure 1 ), the fermentability of the dough gra...

Embodiment 2

[0035] The amount of whey protein isolate in embodiment 2 gluten-free fermented dough

[0036] Take 40g of whole potato powder, 0, 5, 10, 15, 20, 25g of whey protein isolate (WPI), 200g of potato starch, and 1g of HPMC, dissolve in 100g of water at 50°C, stir at a low speed of 80-90rpm for 5min to mix evenly, then mix at a medium speed of 110 Stir at -120rpm for 5min; weigh 2g of yeast and dissolve in 50g of water, activate at 35°C for 10min and add to the above mixture, stir at a medium speed of 110-120rpm for 5min until dough forms. Take 5g of dough and put it into a test tube, then ferment for 50min at 36°C and 85% humidity.

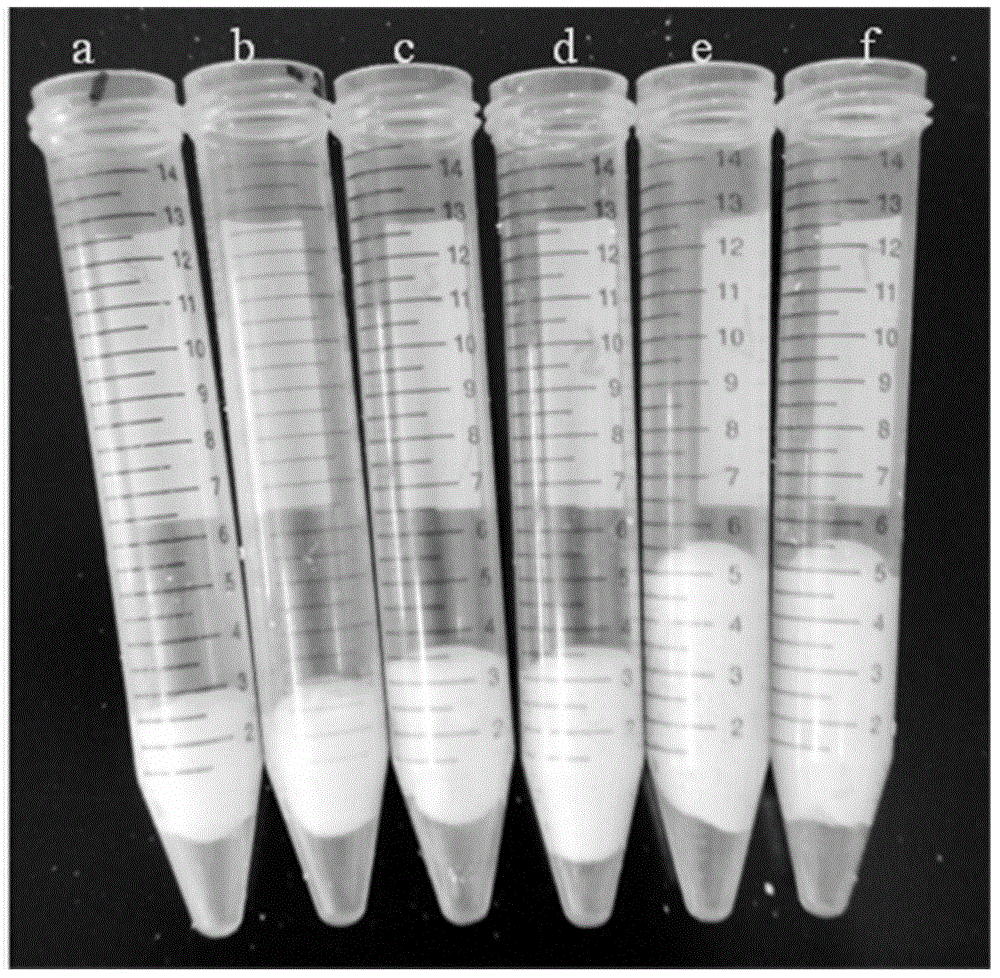

[0037] The dough made by the above method, along with the increase of WPI addition, the fermentability of dough increases, and the fermentation volume increases ( figure 2 ).

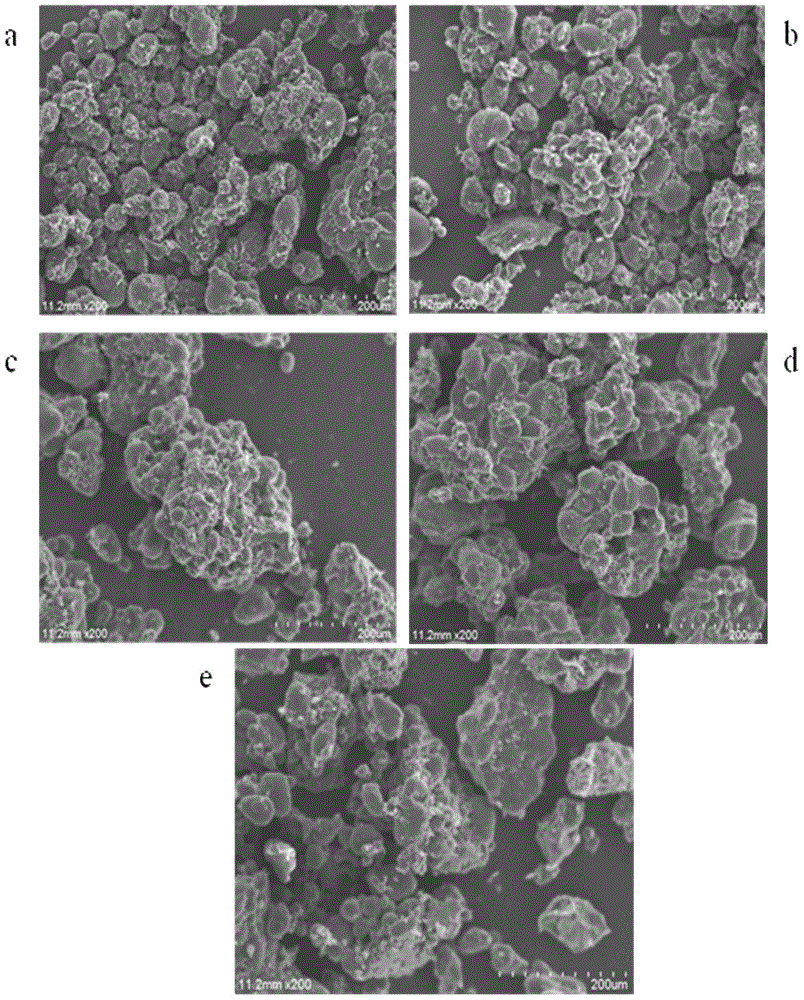

[0038] The effects of different additions of whey protein isolate on the dough structure and the effects of different additions of whey protein isolate on the structure of f...

Embodiment 3

[0039] The preparation of the gluten-free dough of embodiment 3 fermentability and nutritional characteristic improvement

[0040]Dissolve 0.02g of protease A and 0.6g of TGase in 50g of warm water at 30°C and activate for 10 minutes at 50°C; dissolve 2g of yeast in 30g of warm water at 30°C and activate for 10min at 35°C; dissolve 2g of citrus pectin and 0.5g of HPMC in 50g of water at 50°C Make a gel solution; take 80g of potato powder, 100g of potato starch, and 20g of whey protein, add the above gel solution, stir at a low speed of 80-90rpm for 5min and mix well, add the activated protease A and TGase solution at a medium speed of 110-120rpm Stir for 5 minutes, then add the activated yeast solution and 20g of warm water, and stir for 5 minutes at a medium speed of 110-120rpm until the dough is formed. Finally, ferment for 45 minutes at 37°C and 85% humidity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com