An automatic control system for core components of a mass spectrometer

A technology of mass spectrometer and optical system, which is applied in the field of optical system for automatic control of laser analysis spot of mass spectrometer, can solve the problems of controlling the size of laser spot and difficulty in adapting to the needs of application targets, and achieve the effect of enhancing the actual use function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

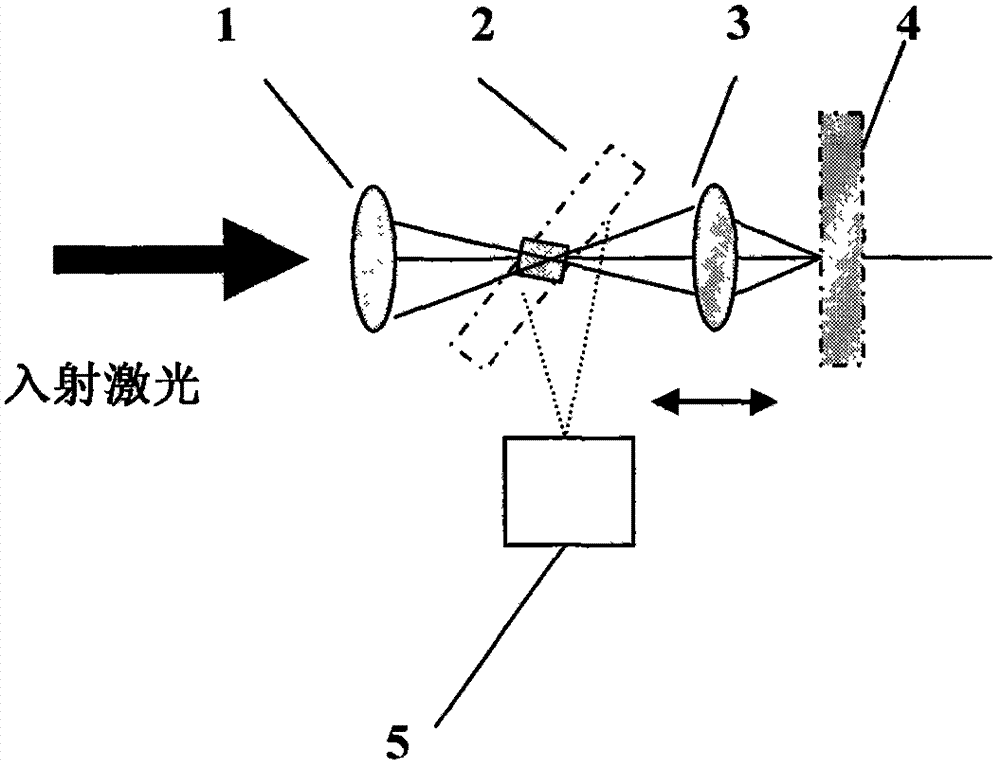

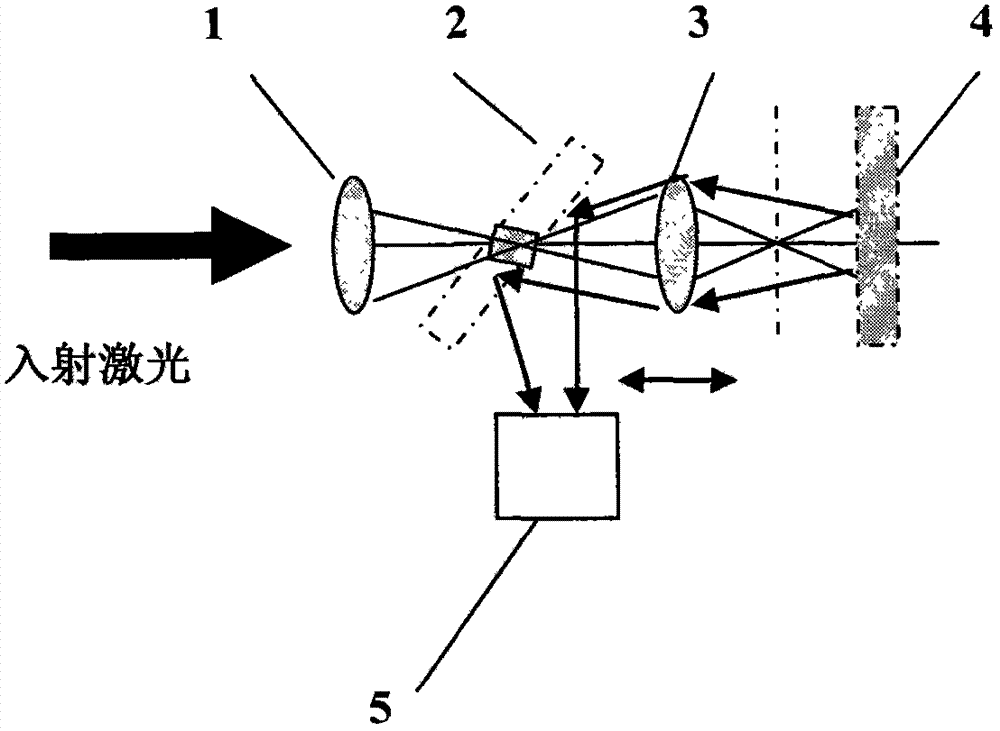

[0013] Such as figure 1 and figure 2 As shown, an optical system for automatic control of the laser analysis spot size of a mass spectrometer consists of an incident lens 1, a mirror 2 with a central transmission hole, a relay lens 3, a correction mirror 4 and a photodetector 5. The incident lens 1, the reflector 2 with the central transmission hole, the relay lens 3 and the correction reflector 4 are arranged in sequence in space, the reflector 2 with the central transmission hole is placed at 45 degrees to the optical axis of the incident laser, and the photodetector 5 placed in the vertical direction of the incident laser optical axis. The incident lens 1 focuses the incident laser light to the central hole position of the reflective mirror 2 with the central transmission hole and makes it pass through the reflective mirror 2 with the central hole, and the relay lens 3 will focus and emit from the reflective mirror 2 with the central transmission hole The laser light is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com