Clamp for compact tension specimen of material testing machine under high pressure hydrogen environment

A compact tensile sample and material testing machine technology, applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve problems such as difficult operation, large additional bending moment, and affecting the authenticity of test results, so as to achieve easy use and improve accuracy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples can make those skilled in the technical field understand the present invention more comprehensively, but do not limit the present invention in any way.

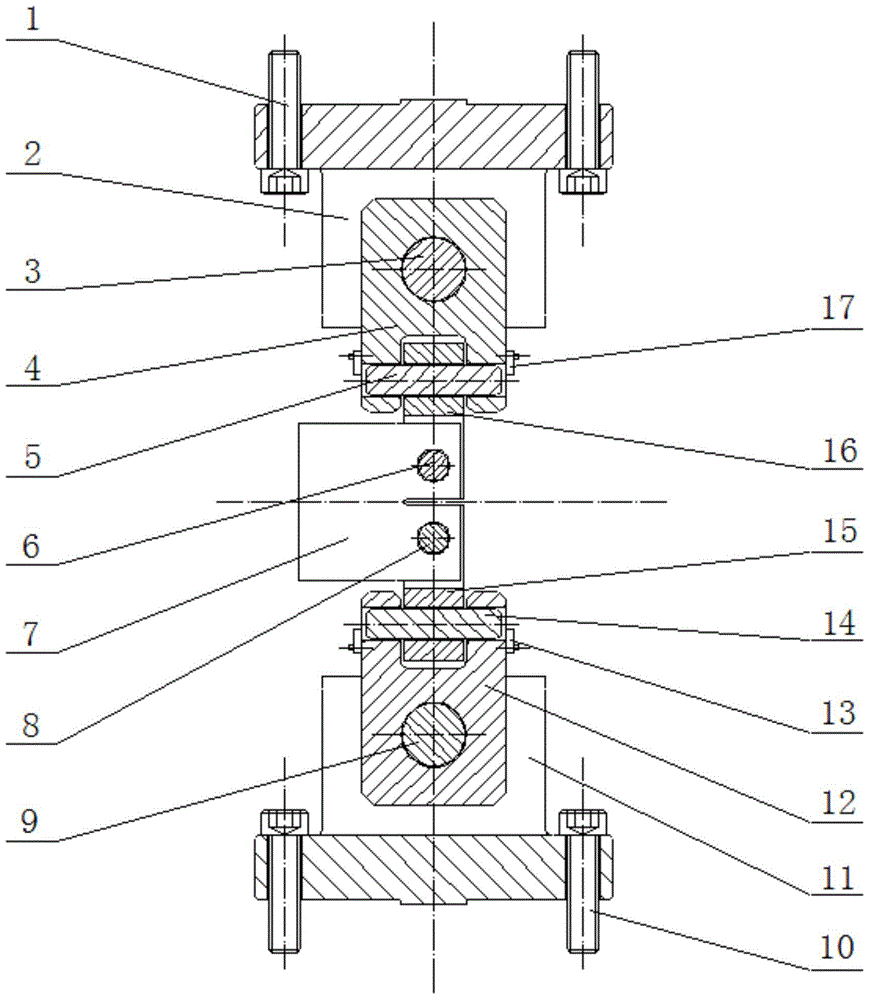

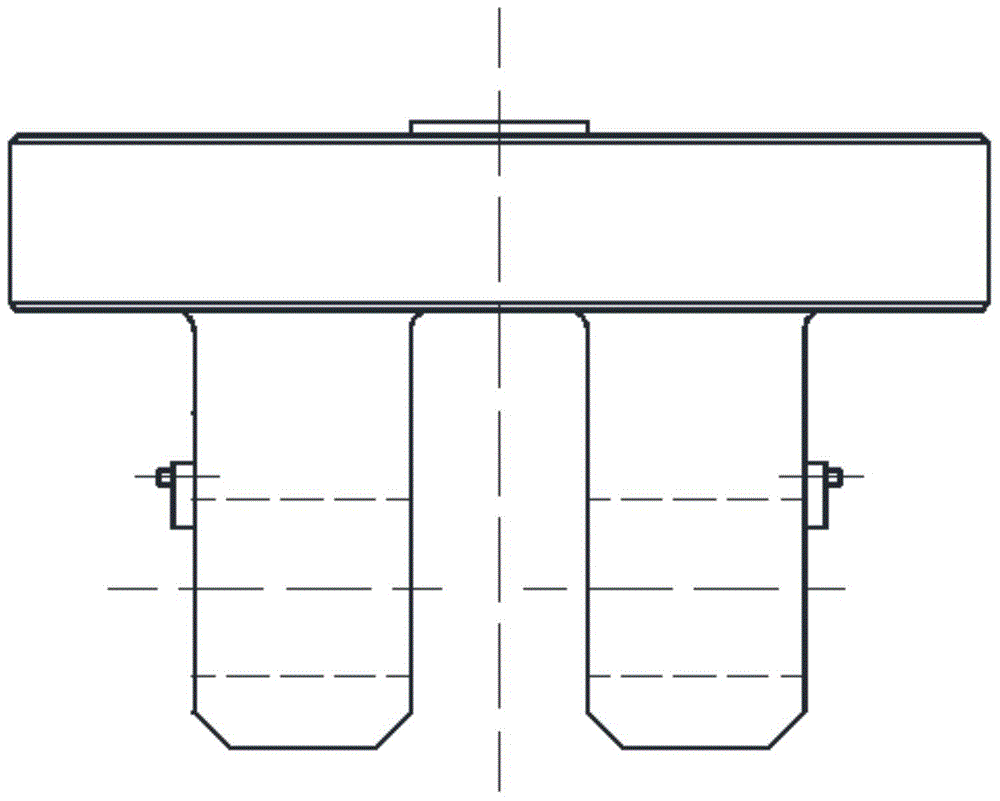

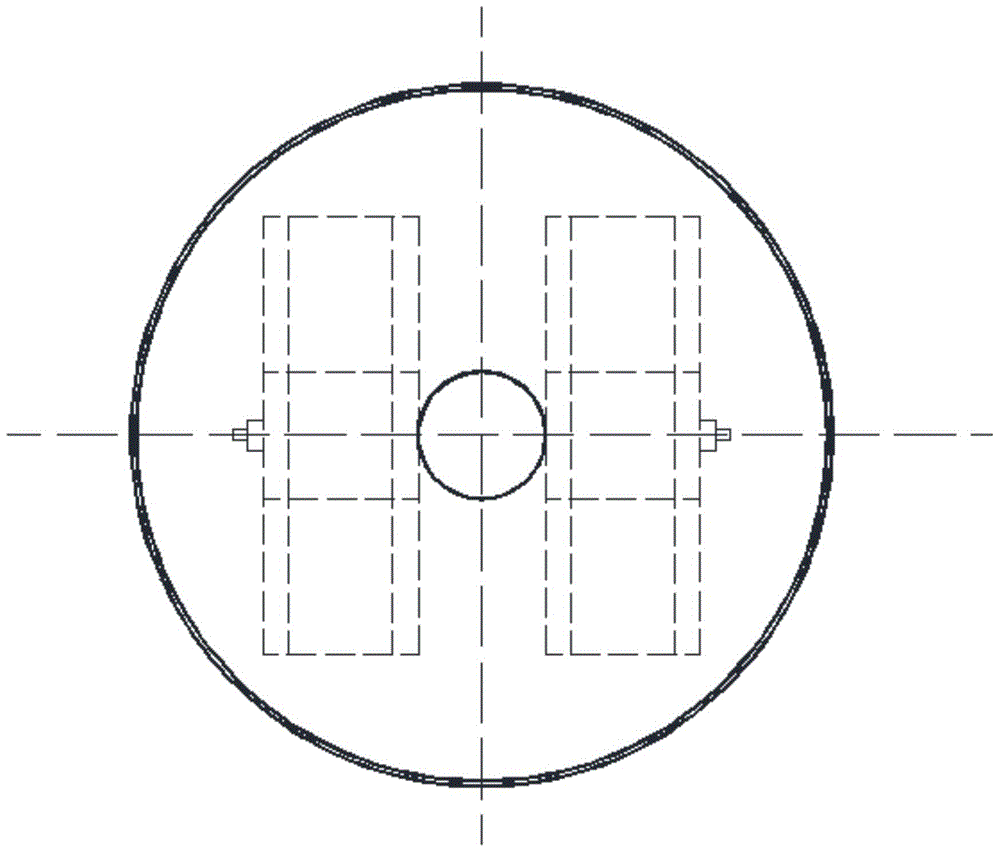

[0023] Such as figure 1 As shown, a specific embodiment of a clamp for a compact tensile sample of a high-pressure hydrogen environment material testing machine is provided, including two parts, an upper clamp and a lower clamp; the upper clamp includes an upper support 2, an upper main U-shaped clamp 4, Last time U-shaped clamp 16, large pin 3 and two small pins (5, 6), wherein: the outer circumference of the cylindrical part of the upper support 2 has a screw hole, which is connected with the upper end of the testing machine through the screw 1, and the rest is composed of two Relative to the rectangular block to form a clamping section, large pin holes are symmetrically opened on the rectangular blocks, and large pin holes are also opened on the symmetrical axis of the rectangular part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com