Hot-rolled round bar for high-pressure oil pipe and manufacturing method

A technology of a high-pressure oil pipe and a manufacturing method, which is applied in the field of hot-rolled round steel for high-pressure oil pipe and its manufacturing field, can solve the problem that the high-pressure oil pipe cannot be satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

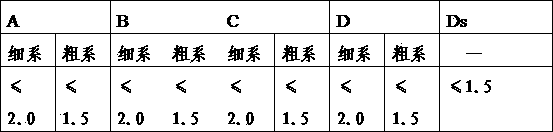

Image

Examples

Embodiment Construction

[0019] The specific implementation of the present invention will be further described below in conjunction with the examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0020] A hot-rolled round steel for high-pressure oil pipes, the chemical composition (smelting composition) mass percentage (wt%) is: C: 0.10 ~ 0.17%, Si: 0.25 ~ 0.45%, Mn: 1.30 ~ 1.60%, P≤0.020% , S≤0.010%, Cr: 0.20 ~ 0.40%, V: 0.05 ~ 0.10%, Al: 0.025 ~ 0.050%, Cu: ≤0.20%, Ni≤0.20%, and the rest is iron and residual trace impurities.

[0021] Preferably, the carbon equivalent of the hot-rolled round steel for high-pressure oil pipes Cev=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15≤0.48%.

[0022] Preferably, the hot-rolled round steel for high-pressure oil pipes contains an appropriate amount of Nb and Ni fine particles.

[0023] A method for manufacturing hot-rolled round steel for high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com