A device and method for treating low-temperature methanol washing ammonium crystallization and purifying barren liquid methanol

A technology of low-temperature methanol washing and methanol water washing tower, which is applied in the fields of combustible gas purification, combustible gas purification/transformation, petroleum industry, etc., can solve problems such as affecting the absorption capacity of lean liquid methanol, increasing the cost of sewage methanol treatment, and increasing methanol consumption, etc. Achieve the effect of promoting recycling, reducing cooling consumption and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

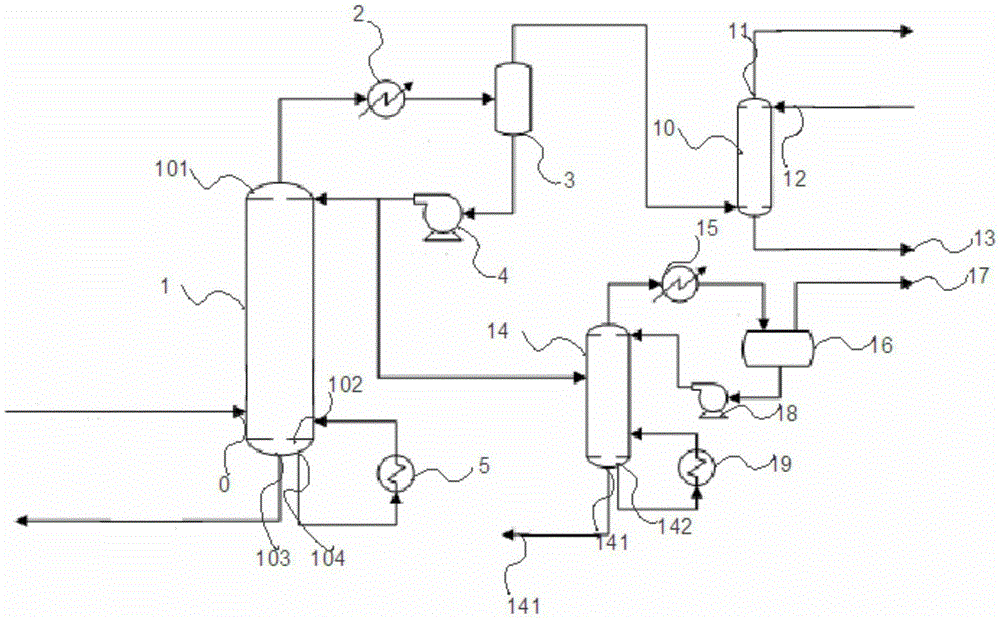

[0040] image 3 It is a schematic process flow diagram of the low-temperature methanol washing heat regeneration system described in Example 1 of the present invention, as image 3 Shown:

[0041] from H 2 The bottom of the S enrichment tower is rich in H 2 The S methanol solution enters the thermal regeneration tower 1 after being reheated. The gas phase at the top 1 of the thermal regeneration tower enters the H 2 After the S water cooler 2 is partially condensed, it enters the gas phase separator 3 at the top of the thermal regeneration tower. One liquid phase returns to the thermal regeneration tower 1, and the other liquid phase enters the alcohol ammonia separation tower 14. The gas phase enters the bottom of the methanol water washing tower, and the waste water at the bottom of the tail gas washing tower enters the top of the methanol water washing tower from the inlet 121 as a washing solution. The gas phase washed with methanol is sent to the downstream sulfur rec...

Embodiment 2

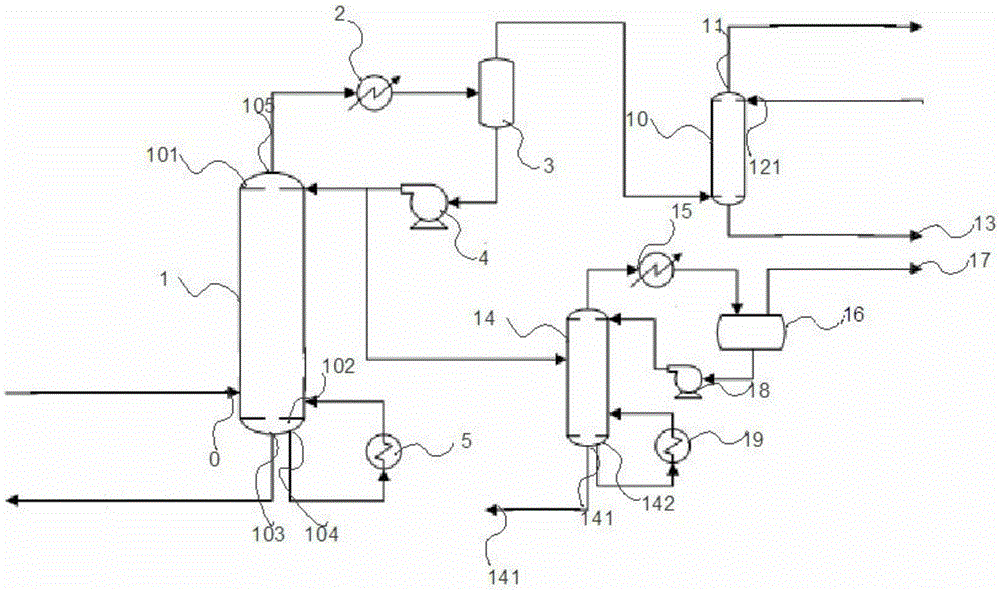

[0056] Figure 4 It is a schematic process flow diagram of the low-temperature methanol washing heat regeneration system described in Example 2 of the present invention, as Figure 4 Shown:

[0057] from H 2 The bottom of the S enrichment tower is rich in H 2 The S methanol solution enters the thermal regeneration tower 1 after being reheated. The gas phase at the top of the thermal regeneration tower enters the H 2 After the S water cooler 2 is partially condensed, it enters the gas phase separator 3 at the top of the thermal regeneration tower. One liquid phase is returned to the thermal regeneration tower 1, and another liquid phase is discharged to the bottom of the alcohol ammonia separation tower 14. The gas phase enters the bottom of the methanol water washing tower 10, and the waste water at the bottom of the tail gas washing tower enters the top of the methanol water washing tower from the inlet 121 as a washing solution. The gas phase washed with methanol is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com