Polished crystal tile manufacturing method and polished crystal tile prepared through same

A manufacturing method and technology of polished crystal bricks, which are applied in the field of ceramic tile manufacturing, can solve problems such as high yield and difficulty in producing metallic luster, and achieve the effects of increased yield, strong metallic texture, and reduced manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

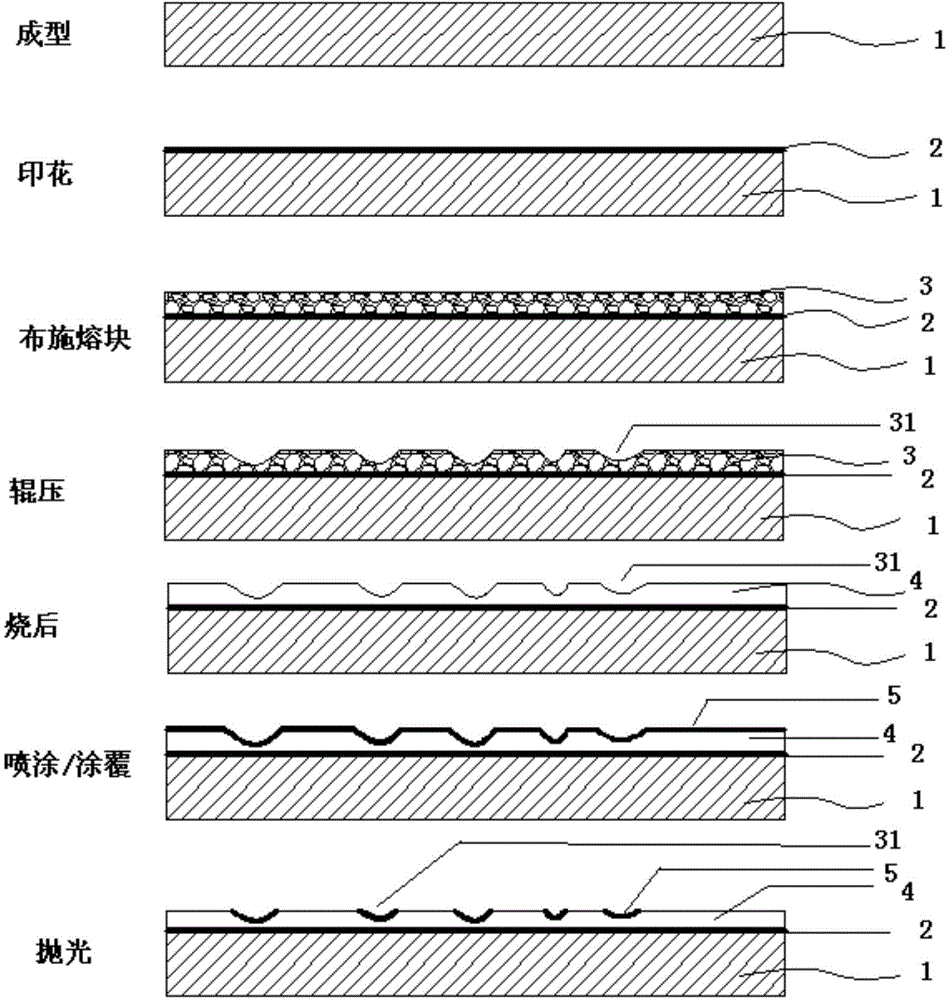

[0032] A polished crystal brick such as figure 1 As shown, it includes a bottom base layer 1, a printing layer 2 and a glass layer 4 from bottom to top, and the surface of the glass layer is distributed with pits 31, and a layer of metallic luster layer 5 is provided on the surface of the pits 31.

[0033] see figure 1 The attached flow chart shows that ceramic tiles with a specification of 1000×1000mm are selected, and the raw materials of the body are well-known in the industry, with feldspar, clay, sand, etc. as the main raw materials, supplemented by talc and other auxiliary materials. Add a whitening zirconium silicate or colored ceramic blank pigment according to actual needs.

[0034] Specifically, refer to figure 1 , its manufacture method comprises the steps:

[0035] A. The raw material ingredients are ball milled and sprayed and granulated (ceramic powder) to be pressed to form brick adobe and dried to form the bottom base layer 1;

[0036] B. Form the printing ...

Embodiment 2

[0046] Refer to attached figure 1 , In this implementation, the polished crystal brick with a specification of 1000×1000mm is manufactured, and its manufacturing process includes the following steps in turn:

[0047] A. The raw material ingredients are ball milled and sprayed to granulate, and then pressed to form bricks and dried to form the bottom base layer 1;

[0048] B. Form the printing layer 2 by roller printing and then cloth the transparent frit to form the transparent frit layer 3;

[0049] C. Spray 0.1% PVA solution fixative for fixation, and press out the lines with the embossed mold of the glue before the fixative is dry, so that the frit layer 3 has a depth of 1-3mm in different shades and sizes. a dimple 31;

[0050] D. Firing: firing in a roller kiln at 1100-1250°C under an oxidizing atmosphere, with a firing cycle of 90-120 minutes;

[0051] E. Spray one layer of fineness 300 mesh sieve in the fired semi-finished product pit 31, the viscosity is 200cps, and...

Embodiment 3

[0056] Refer to attached figure 1 , In this implementation, the polished crystal brick with a specification of 1000×1000mm is manufactured, and its manufacturing process includes the following steps in turn:

[0057] A. The raw material ingredients are ball milled for spray granulation, and then pressed to form adobe and dried to form the bottom base layer 1;

[0058] B. Form the printing layer 2 by inkjet printing, roller printing, and screen printing in sequence, and then form the transparent frit layer 3 with transparent frit;

[0059] C. Spray PVA solution fixative with a content of 0.08% for fixation, and use the embossed mold to press out the lines before the fixative is dry, so that the frit layer has a depth of 1-4mm in different shades and sizes the dimple 31;

[0060] D. Firing: firing in a roller kiln at 1100-1250°C under an oxidizing atmosphere, with a firing cycle of 90-120 minutes;

[0061] E. Spray a layer of fineness 450 mesh sieve in the fired semi-finished...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com