Titanium dioxide/metal core-shell structure composite nano-particle and preparing method thereof

A technology of composite nanoparticles and titanium dioxide, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, nanotechnology, etc., can solve the problem that the surface area cannot be fully utilized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

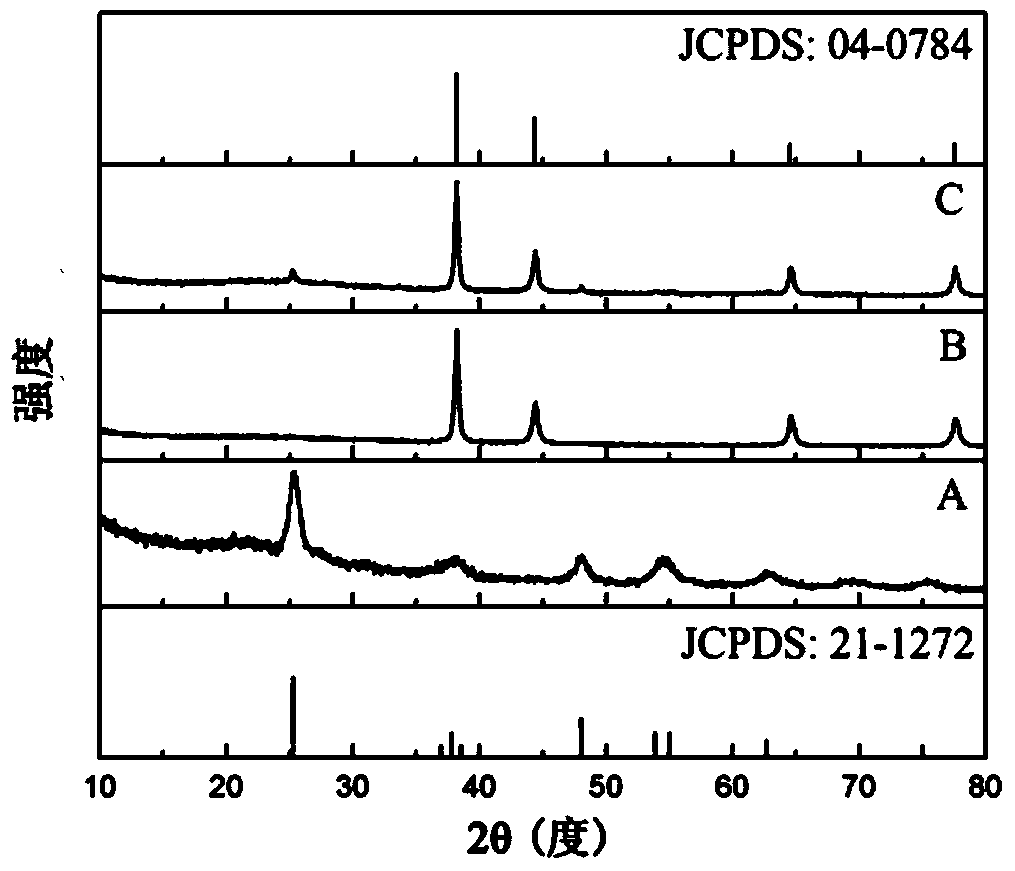

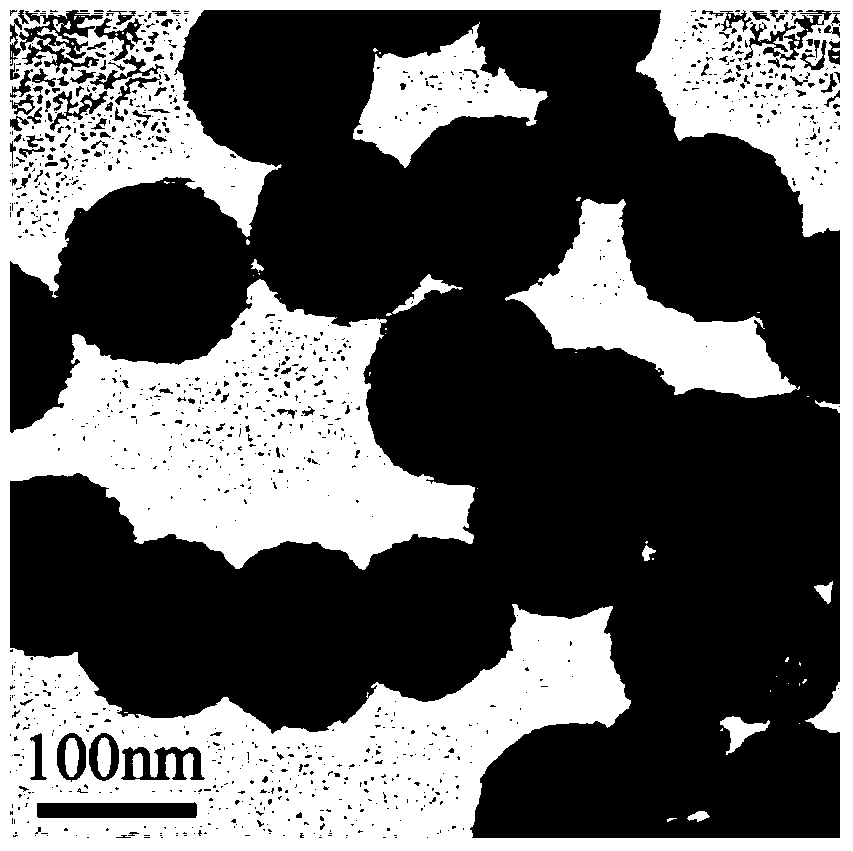

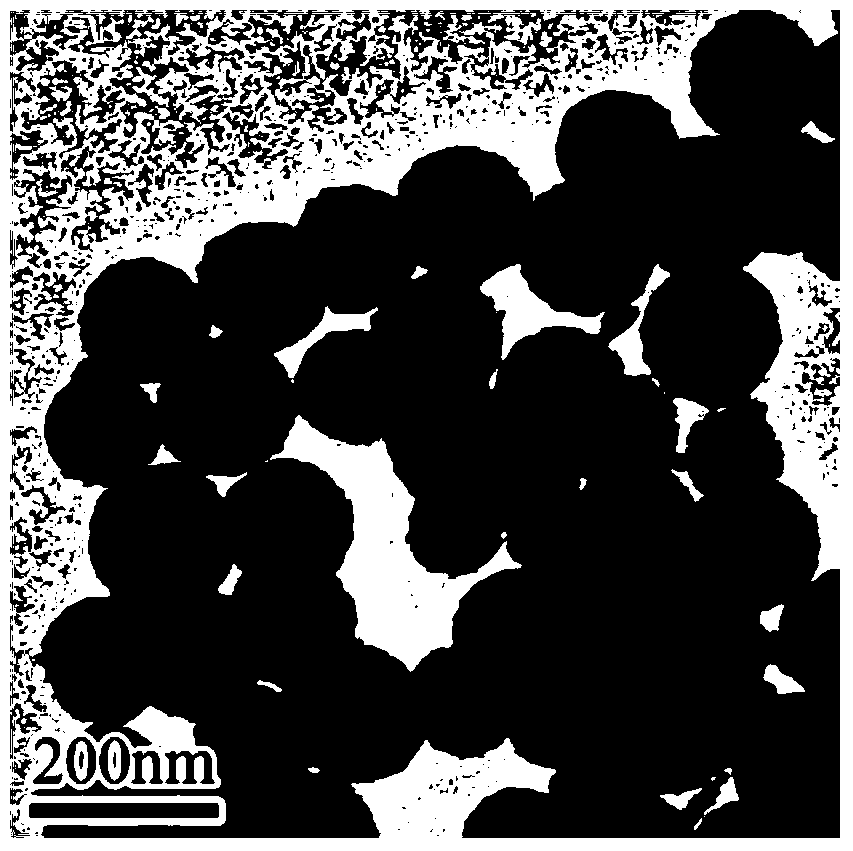

[0037] Correspondingly, the present invention also provides a preparation method of titanium dioxide / gold core-shell composite nanoparticles, comprising the following steps:

[0038] a) providing an aqueous solution of titanium dioxide hollow nanoparticles whose inner surface is modified with amino groups;

[0039] b) Dispersing the aqueous solution of titanium dioxide hollow nanoparticles with amino groups modified on the inner surface in the aqueous solution of chloroauric acid, ultrasonically reacting after the first stirring in the dark, heating in a water bath at 40-80°C, and stirring for the second time in the dark centrifuged and dried to obtain AuTiO 2 Composite nanoparticles, which means coated;

[0040] c) the AuTiO 2 The composite nanoparticles are annealed at high temperature to obtain titanium dioxide / gold core-shell composite nanoparticles.

[0041]The invention uses titanium dioxide hollow nanoparticles modified with amino groups on the inner surface as raw m...

Embodiment 1

[0062] a. In a 50ml glass bottle, mix cyclohexane, Tritox X-100, n-hexanol, deionized water and ammonia water evenly, with a volume ratio of 150:35:35:8:2, and stir until clear and transparent;

[0063] b. 300 microliters of tetraethyl orthosilicate, 150 microliters of N-aminoethyl-γ-aminopropyltrimethoxysilane and 1 milliliter of cyclohexane were mixed evenly, and then added to the mixed solution in the previous step at one time, Stir for 24 hours;

[0064] c. Add an equal volume of ethanol to the mixed solution formed in the previous step to break the emulsion, then centrifuge and wash it, and then disperse it in 16 ml of isopropanol to form O-SiO with a concentration of 0.1 mol / L 2 Nanosphere isopropanol solution, "O" means organic hybrid.

[0065] d. In a 50 ml glass bottle, mix isopropanol, deionized water and ammonia water to form a mixed solution, and 1 ml of O-SiO with a concentration of 0.1 mol / L 2 The nanosphere isopropanol solution is added to the aforementioned m...

Embodiment 2

[0072] a. In a 50ml glass bottle, mix cyclohexane, Tritox X-100, n-hexanol, deionized water and ammonia water evenly, with a volume ratio of 150:35:35:8:2, and stir until clear and transparent;

[0073] b. 300 microliters of tetraethyl orthosilicate, 150 microliters of N-aminoethyl-γ-aminopropyltrimethoxysilane and 1 milliliter of cyclohexane were mixed evenly, and then added to the mixed solution in the previous step at one time, Stir for 24 hours;

[0074] c. Add an equal volume of ethanol to the mixed solution formed in the previous step to break the emulsion, then centrifuge and wash it, and then disperse it in 16 ml of isopropanol to form O-SiO with a concentration of 0.1 mol / L 2 Nanosphere isopropanol solution, "O" means organic hybrid.

[0075] d. In a 50 ml glass bottle, mix isopropanol, deionized water and ammonia water to form a mixed solution, and 1 ml of O-SiO with a concentration of 0.1 mol / L 2 The nanosphere isopropanol solution is added to the aforementioned m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com