Durable dental material with improved transparent properties

A dental material and dental technology, which can be used in dental impression materials, medical preparations with non-active ingredients, dentistry, etc., and can solve the problems of insufficient opacity of dental materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

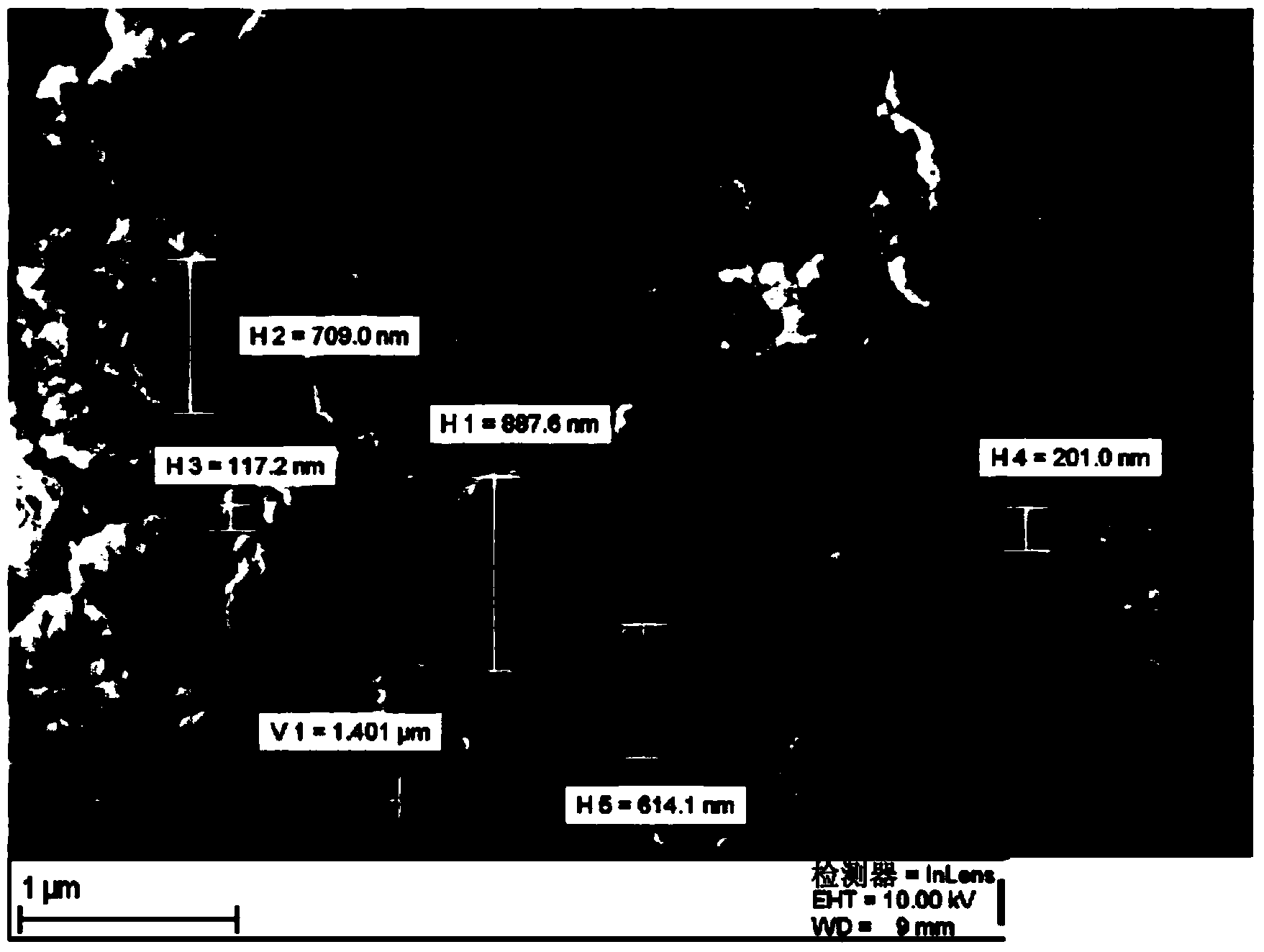

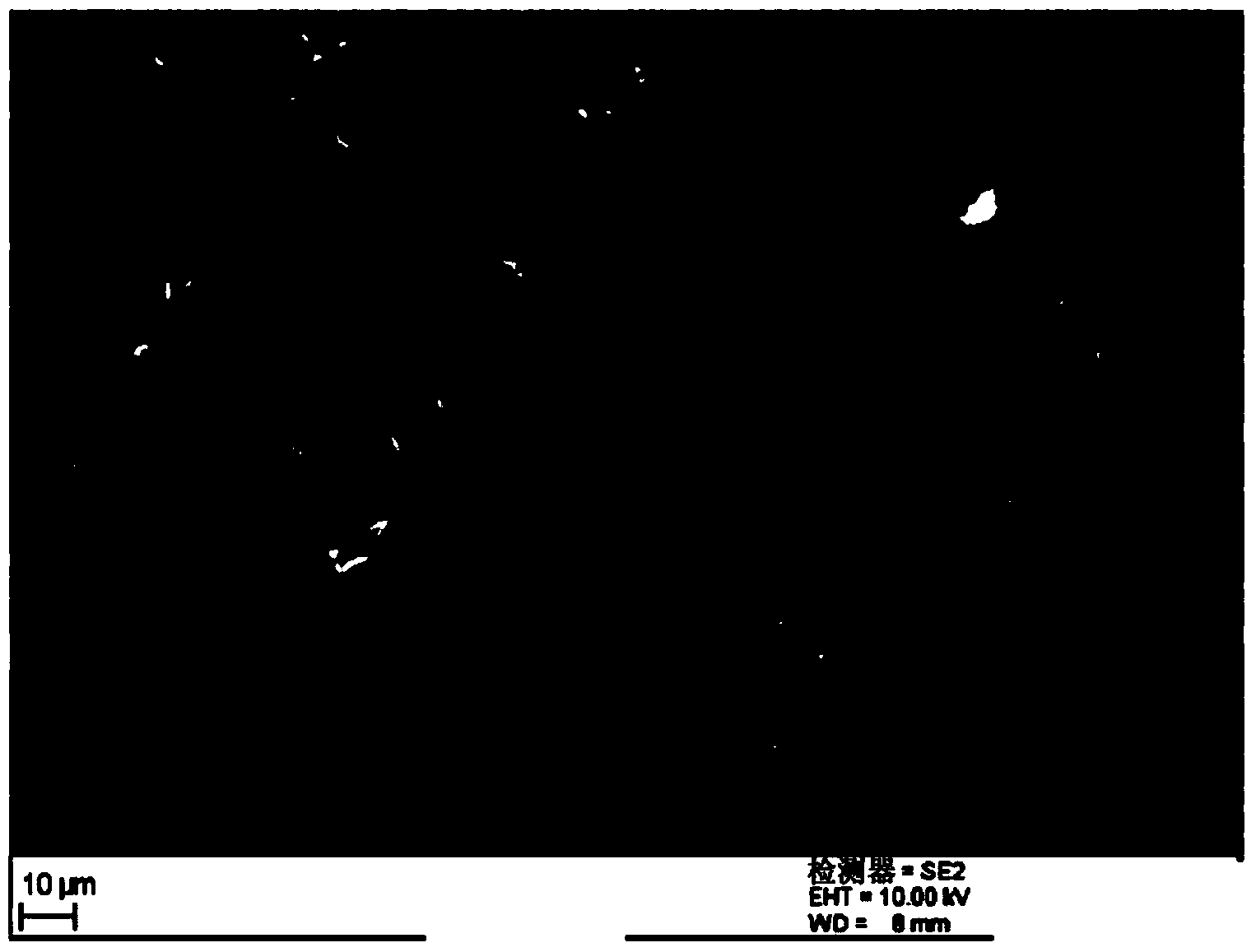

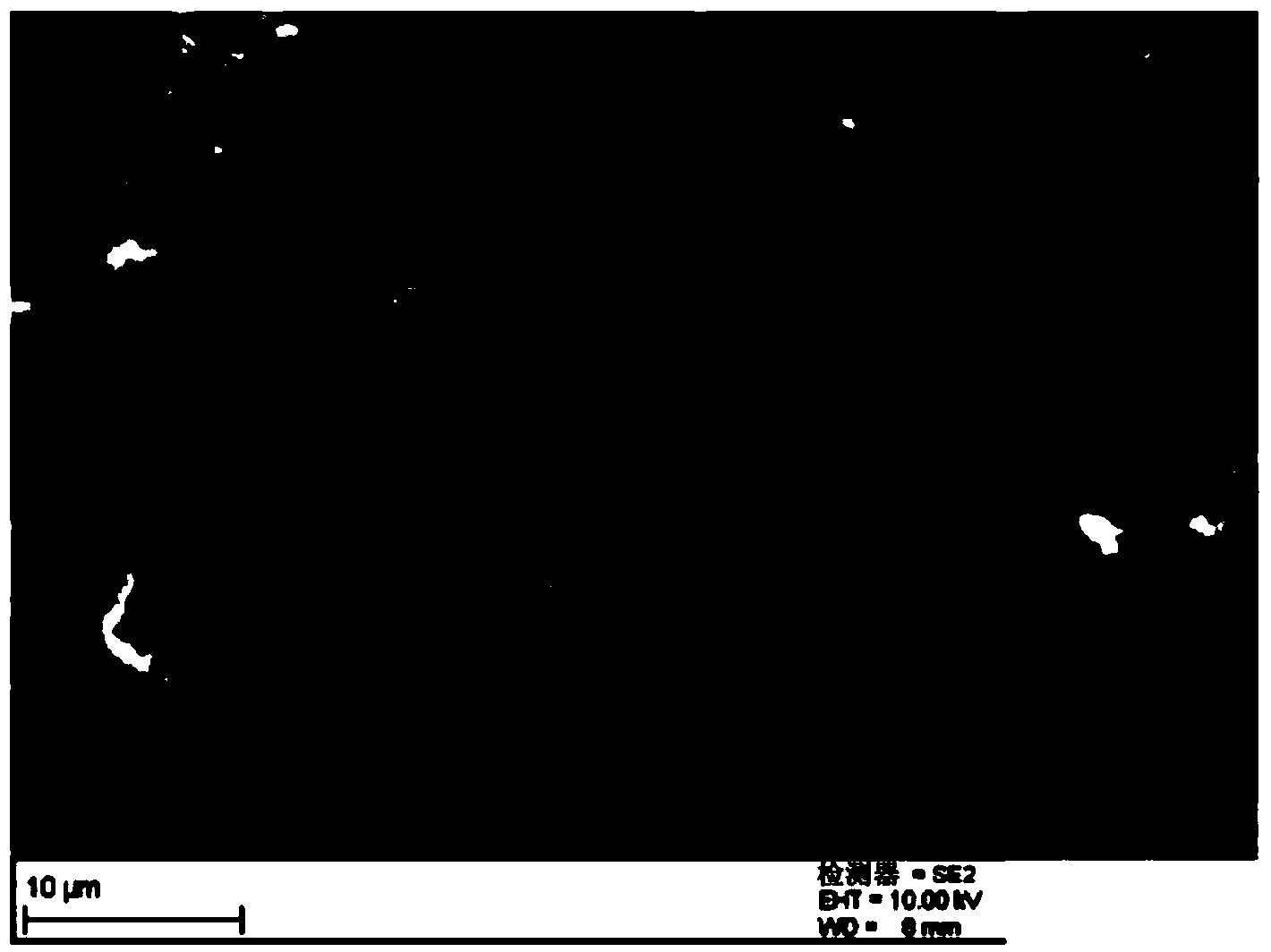

Image

Examples

Embodiment Construction

[0070] Measurement of abrasive properties

[0071] The wear behavior of dental materials was determined using a testing machine manufactured by the company Willytec / SD-Mechatronik. In general, abrasion and tearing of natural teeth or dental materials due to in vivo wear can result from a variety of mechanisms, such as abrasion due to antagonistic teeth, abrasion due to abrasive particles in chewed food, and / or wear and tear due to cleaning with toothbrush and / or toothpaste. The mechanism of wear and tear can be simulated under laboratory conditions by various simulation methods.

[0072] 3- Moderate abrasion (ACTA-method) is used to simulate the abrasion caused by chewing food: the material to be tested is placed in a rotating wheel with 12 Made, 240min -1 ) in the opposite direction at 180min -1 run. The two wheels are supported by bearings in a suspension of water and poppy seeds (Poppy Seed Abrasive, MA, 110 g poppy: 200 g water). The counter wheel is pressed ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com