High-power microwave (HPM) medium window for improving vacuum side power capacity

A high-power microwave and power-capacity technology, applied in waveguide-type devices, electrical components, circuits, etc., can solve the problem that the electric field polarization direction slot distribution cannot be determined.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

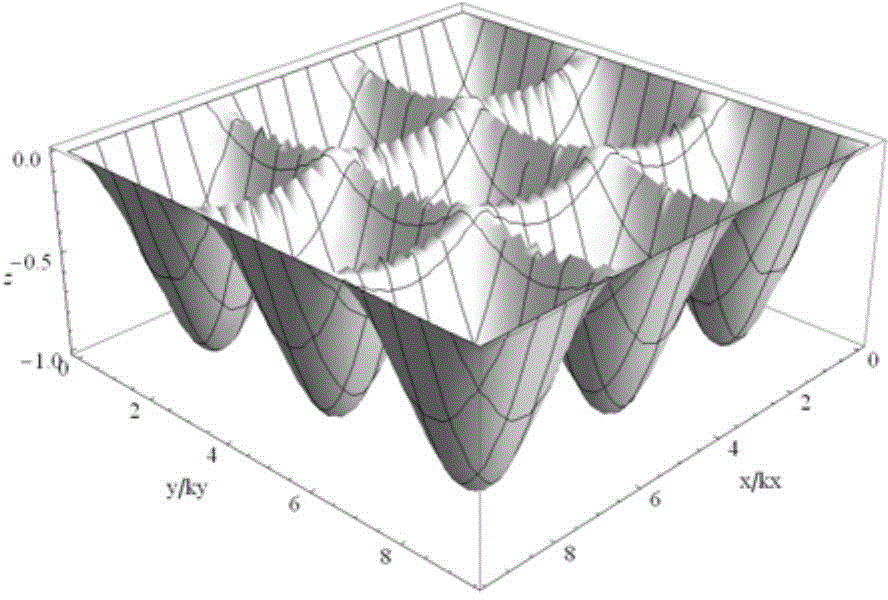

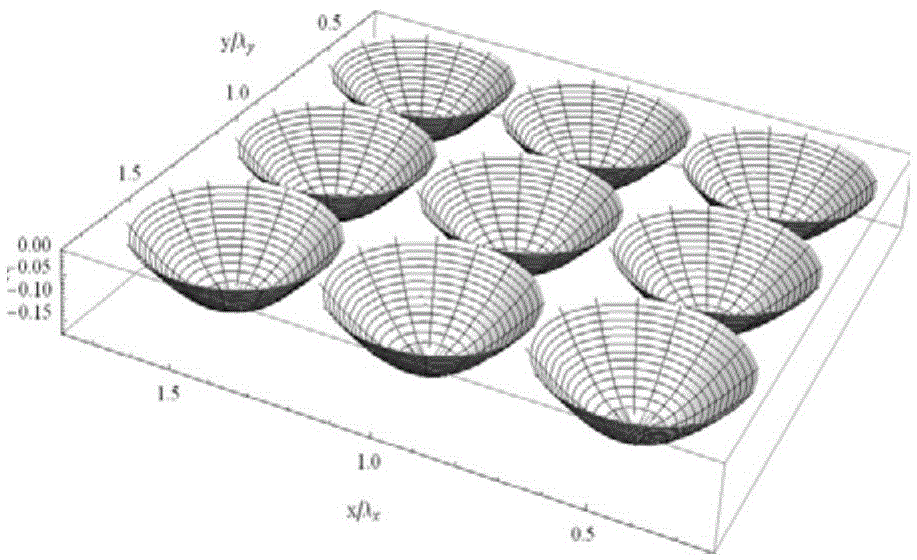

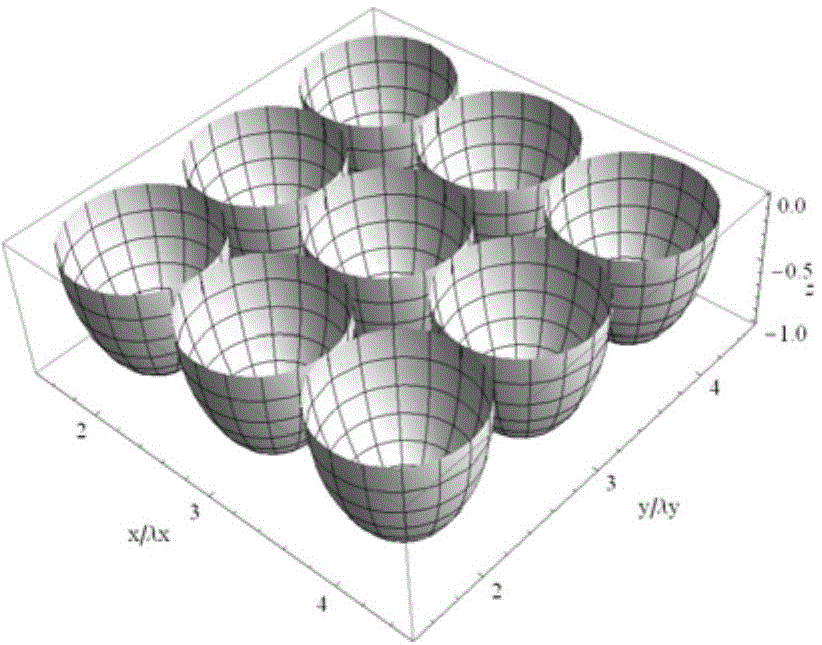

[0049] The invention provides a high-power microwave dielectric window which improves the power capacity of the vacuum side. The surface of the high-power microwave dielectric window is composed of several curved surface periodic structural units. In the present invention, the surface formed by the curved periodic structural unit is preferably a three-dimensional periodic function surface. The present invention constrains electrons in the functional structure through a three-dimensional periodic function surface, changes the trajectory, transit time and collision energy of the multiplied electrons, and uses microwaves (frequency f×10 9 Hz) The restoring force provided by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com