Lithium ion battery pole piece and preparation method thereof

A lithium ion battery and pole piece technology is applied in the field of lithium ion battery pole pieces and their preparation to achieve the effects of enhancing the bonding effect, improving the cycle stability system and curbing shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

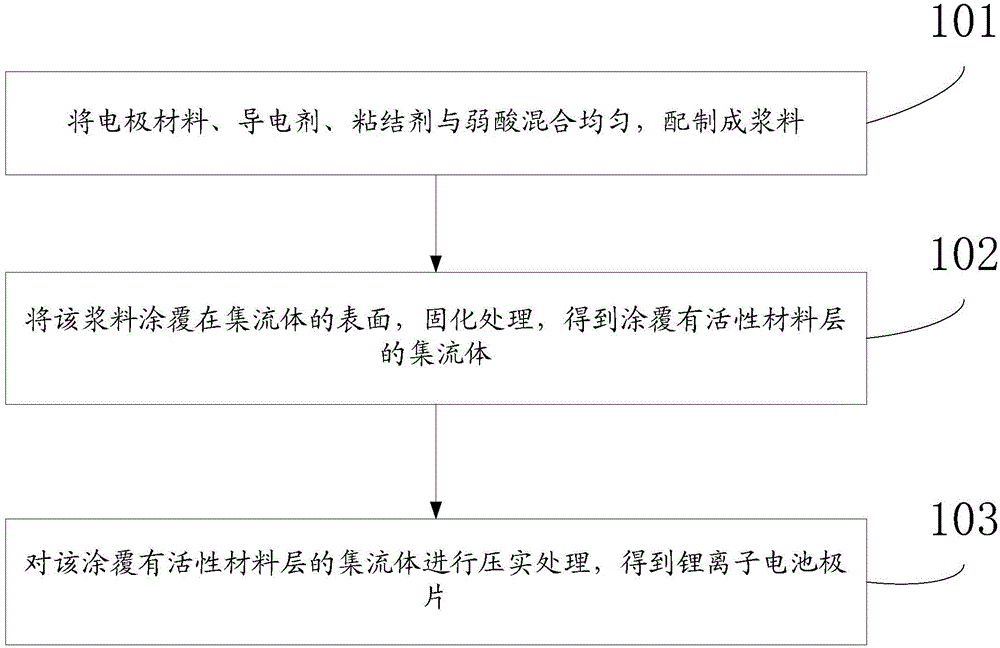

[0049] In the third aspect, the embodiment of the present invention provides a method for preparing a lithium-ion battery pole piece, with figure 1 A flow chart of the preparation method. as attached figure 1 As shown, the method includes:

[0050] Step 101. Mix electrode material, conductive agent, binder and weak acid evenly to prepare slurry.

[0051] Step 102 , coating the slurry on the surface of the current collector and curing it to obtain a current collector coated with an active material layer.

[0052] Step 103, compacting the current collector coated with the active material layer to obtain a lithium-ion battery pole piece.

[0053] Wherein, the amount of the weak acid in step 101 is suitable to be able to corrode the current collector and make the surface of the current collector have a roughness of 0.3-3.5 microns.

[0054] In the method provided by the embodiment of the present invention, weak acid is used to slightly corrode the surface of the current collec...

Embodiment 1

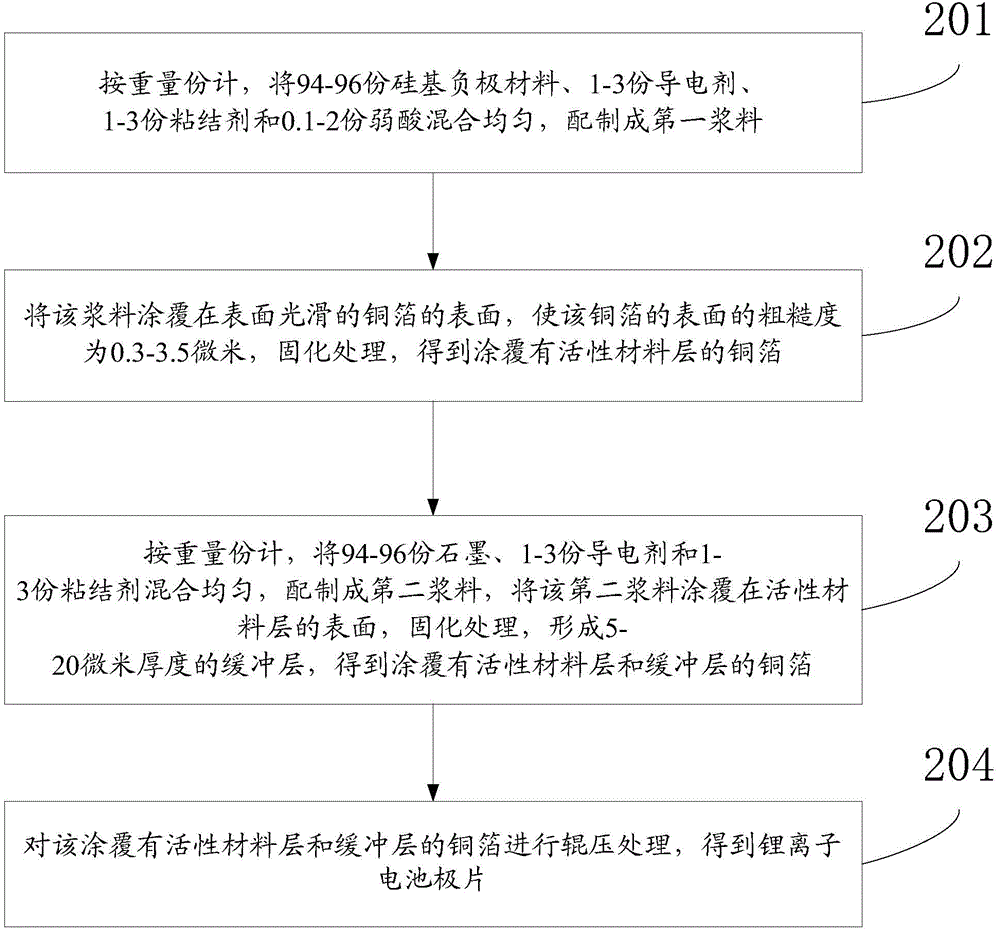

[0067] In parts by weight, 94 parts of the silicon carbon material, 3 parts of the conductive agent, and 3 parts of the binder were uniformly mixed. Then add 2 parts of oxalic acid therein, stir evenly again, obtain the first slurry. The prepared first slurry is evenly coated on the surface of the copper foil with a smooth surface so that the surface roughness of the copper foil is 1.0 μm, and cured to obtain the copper foil coated with the active material layer.

[0068] In parts by weight, 94 parts of graphite, 3 parts of conductive agent and 3 parts of binder are mixed evenly to prepare a second slurry, which is coated on the surface of the obtained active material layer to form a buffer layer , and make the buffer layer have a thickness of 10 microns to obtain a copper foil coated with an active material layer and a buffer layer. The copper foil coated with the active material layer and the buffer layer was rolled to obtain the desired lithium-ion battery pole piece in th...

Embodiment 2

[0072] In parts by weight, 96 parts of the silicon carbon material, 2 parts of the conductive agent, and 2 parts of the binder are uniformly mixed. Then add 2 parts of formic acid therein, stir evenly again, obtain the first slurry. The prepared first slurry was evenly coated on the surface of the copper foil with a smooth surface so that the surface roughness of the copper foil was 1.5 μm, and cured to obtain the copper foil coated with the active material layer.

[0073] In parts by weight, 95 parts of graphite, 3 parts of conductive agent and 2 parts of binder are uniformly mixed to prepare a second slurry, which is coated on the surface of the obtained active material layer to form a buffer layer , and make the buffer layer have a thickness of 20 microns to obtain a copper foil coated with an active material layer and a buffer layer. The copper foil coated with the active material layer and the buffer layer was rolled to obtain the desired lithium-ion battery pole piece i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com